The End of GCode

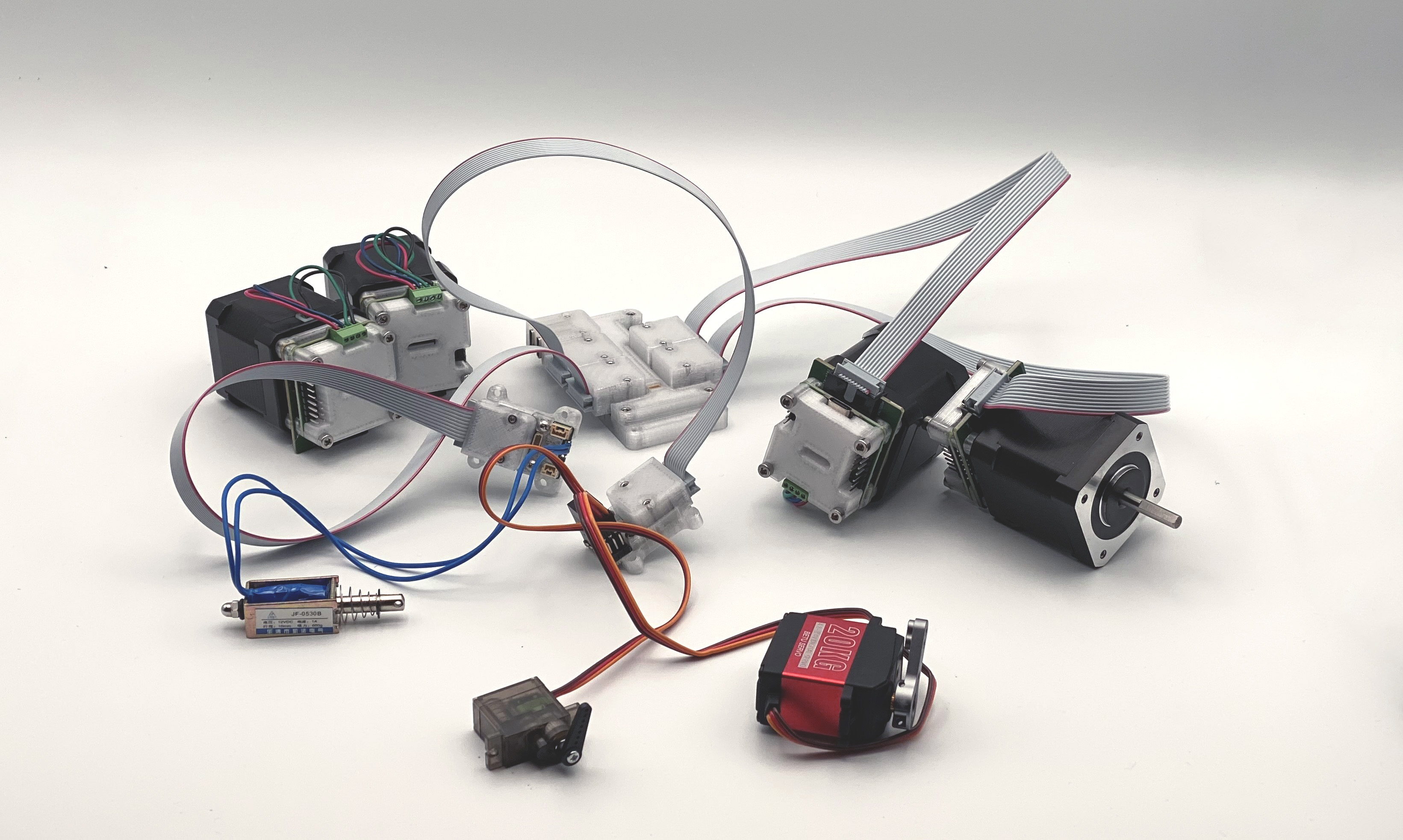

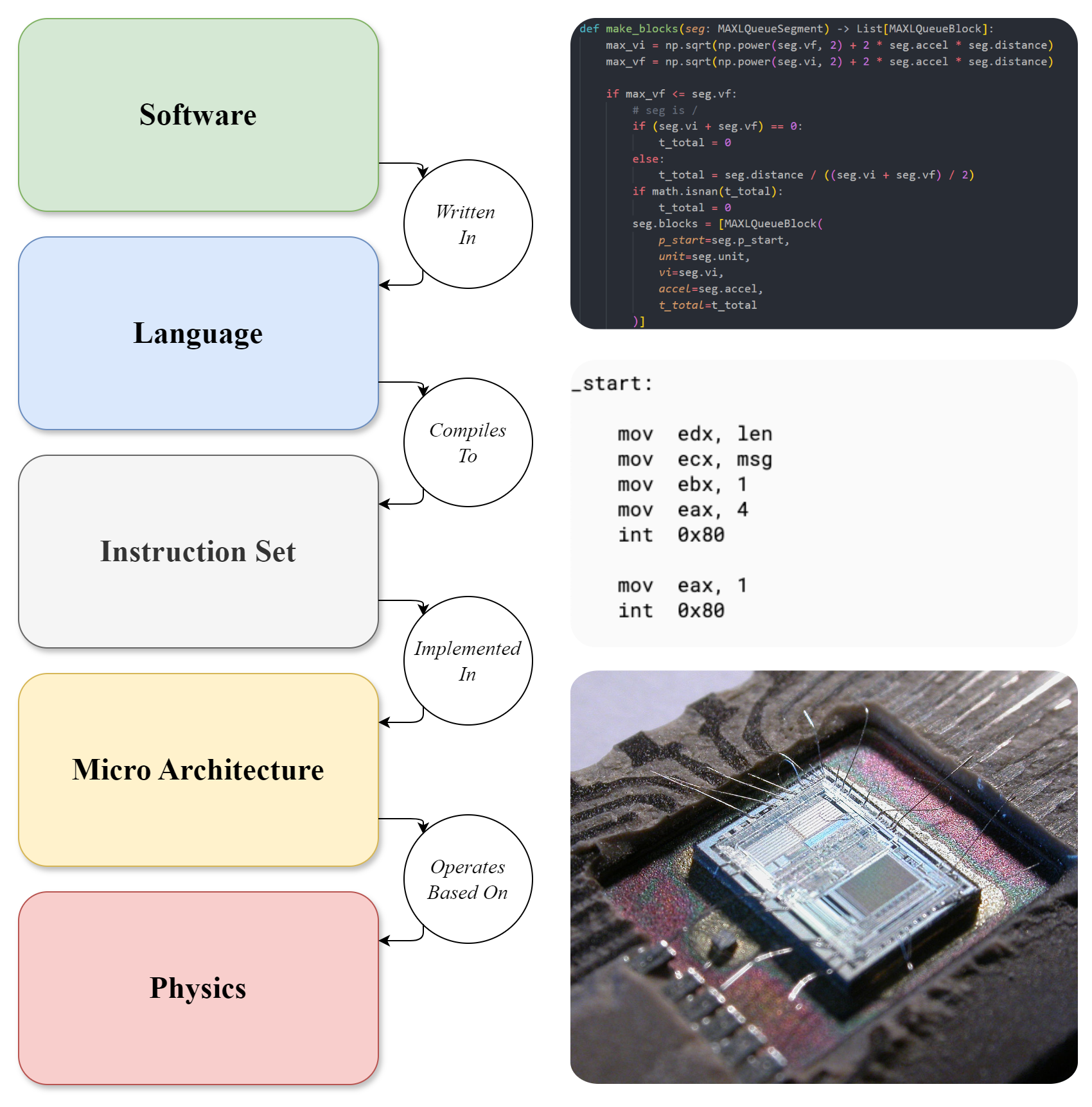

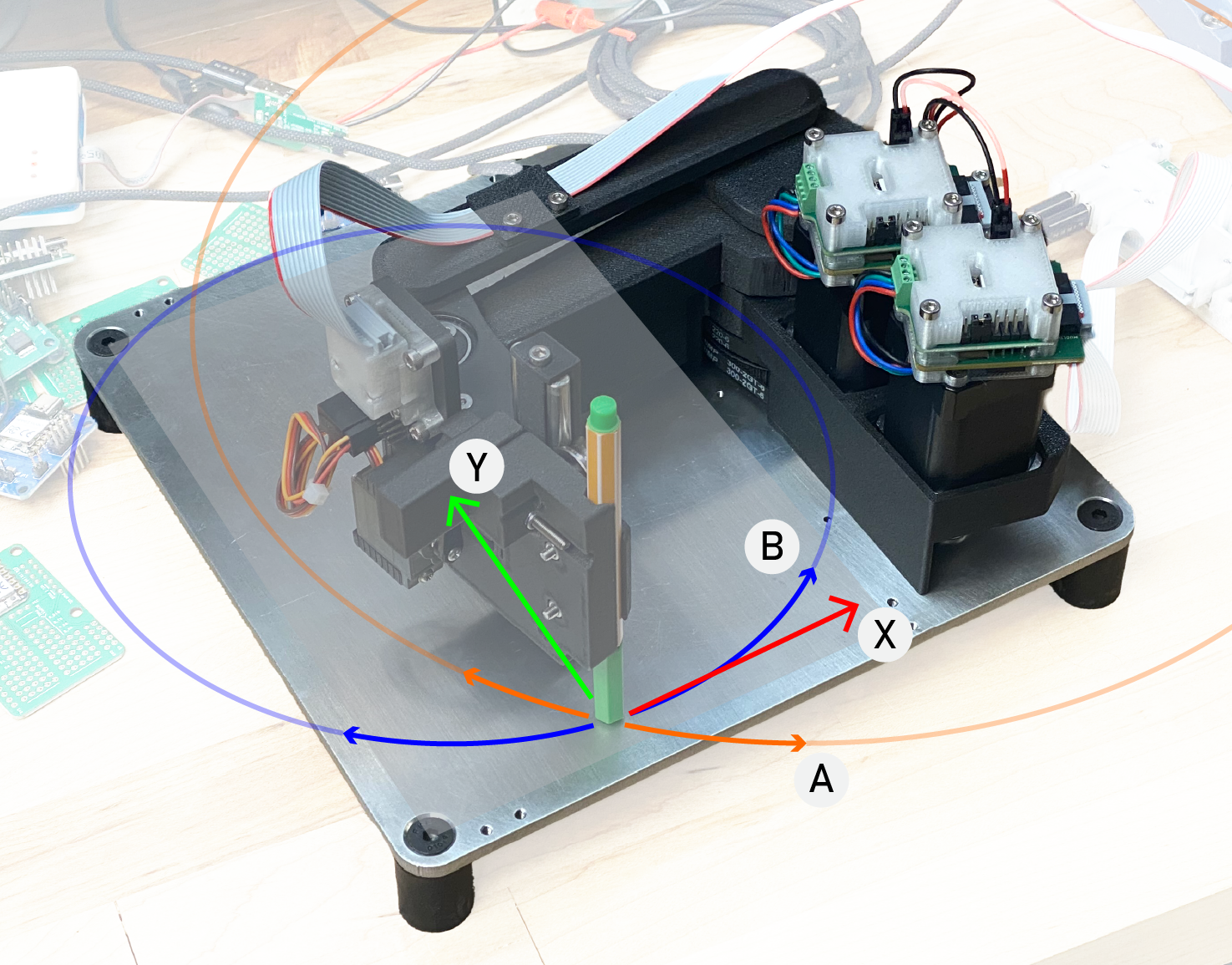

Machine Architectures for Feedback Systems Assembly

PhD Thesis Proposal

Jake Robert Read

MIT Center for Bits and Atoms

Neil Gershenfeld

Director, Center for Bits and Atoms

Massachusetts Institute of Technology

Director, Center for Bits and Atoms

Massachusetts Institute of Technology

Nadya Peek

Associate Professor, Human Centered Design and Engineering

University of Washington

Associate Professor, Human Centered Design and Engineering

University of Washington

Jon Seppala

Director, nSoft Consortium

National Institute of Standards and Technology

Director, nSoft Consortium

National Institute of Standards and Technology

How can we make it easier to use and understand machines?

How can we make it easier to develop and improve machines?

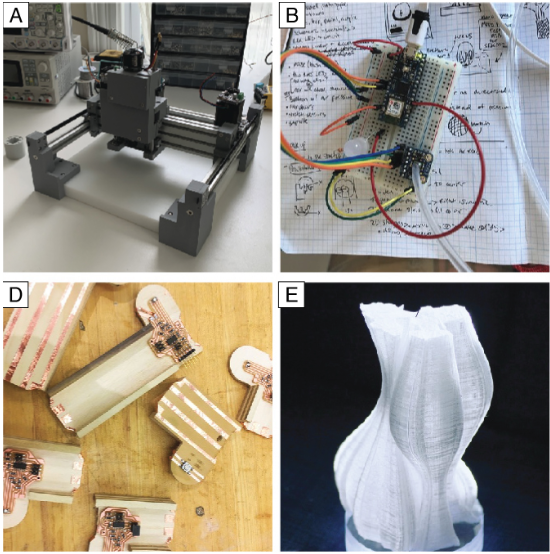

Peek, Nadya, et al. "Making at a distance: teaching hands-on courses during the pandemic."

Extended Abstracts of the 2021 CHI Conference on Human Factors in Computing Systems. 2021.

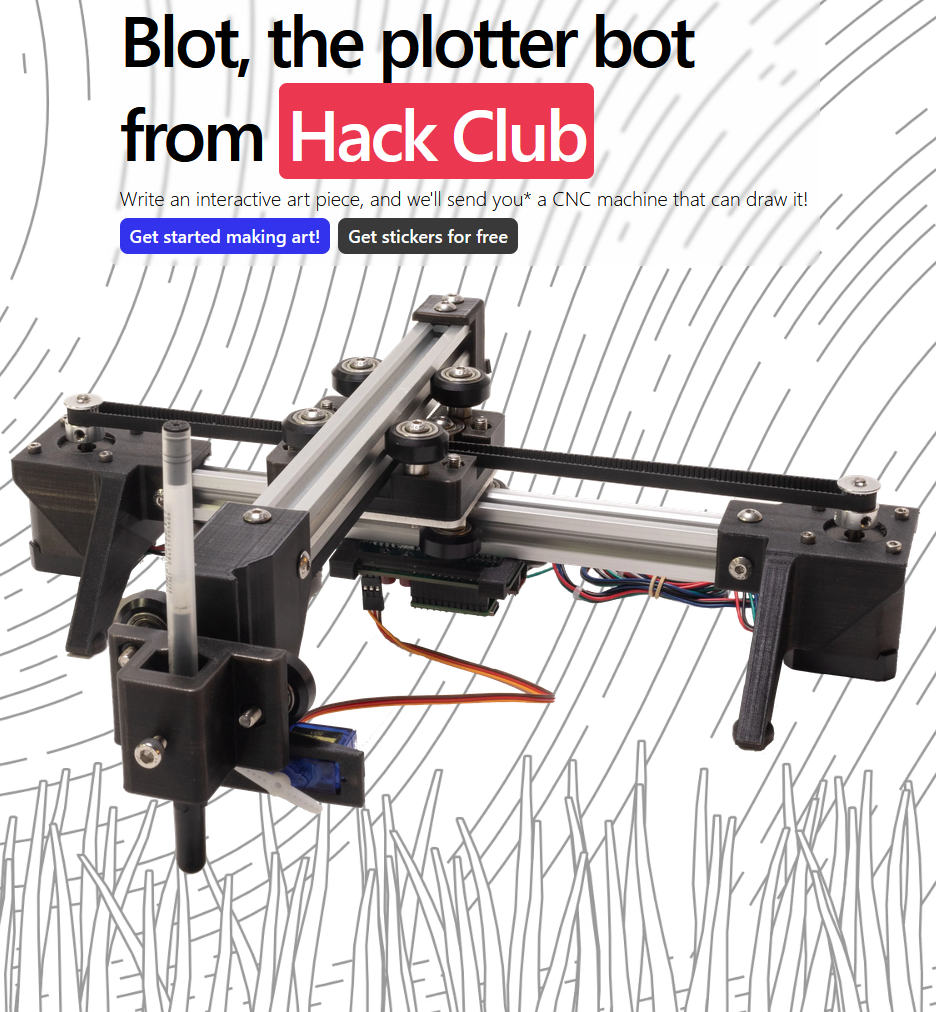

Hack Club and Leo McElroy

https://blot.hackclub.com/

https://blot.hackclub.com/

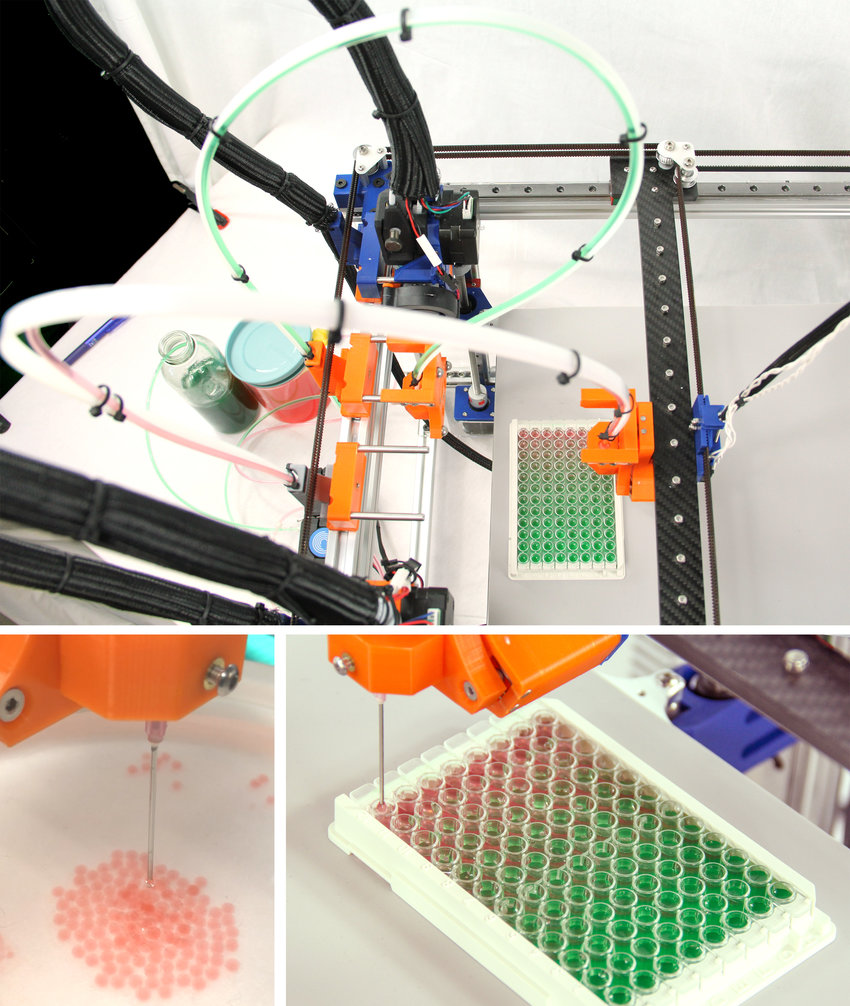

Vasquez, Joshua, et al. "Jubilee Demo: An Extensible Machine for Multi-Tool Fabrication."

Extended Abstracts of the 2020 CHI Conference on Human Factors in Computing Systems. 2020.

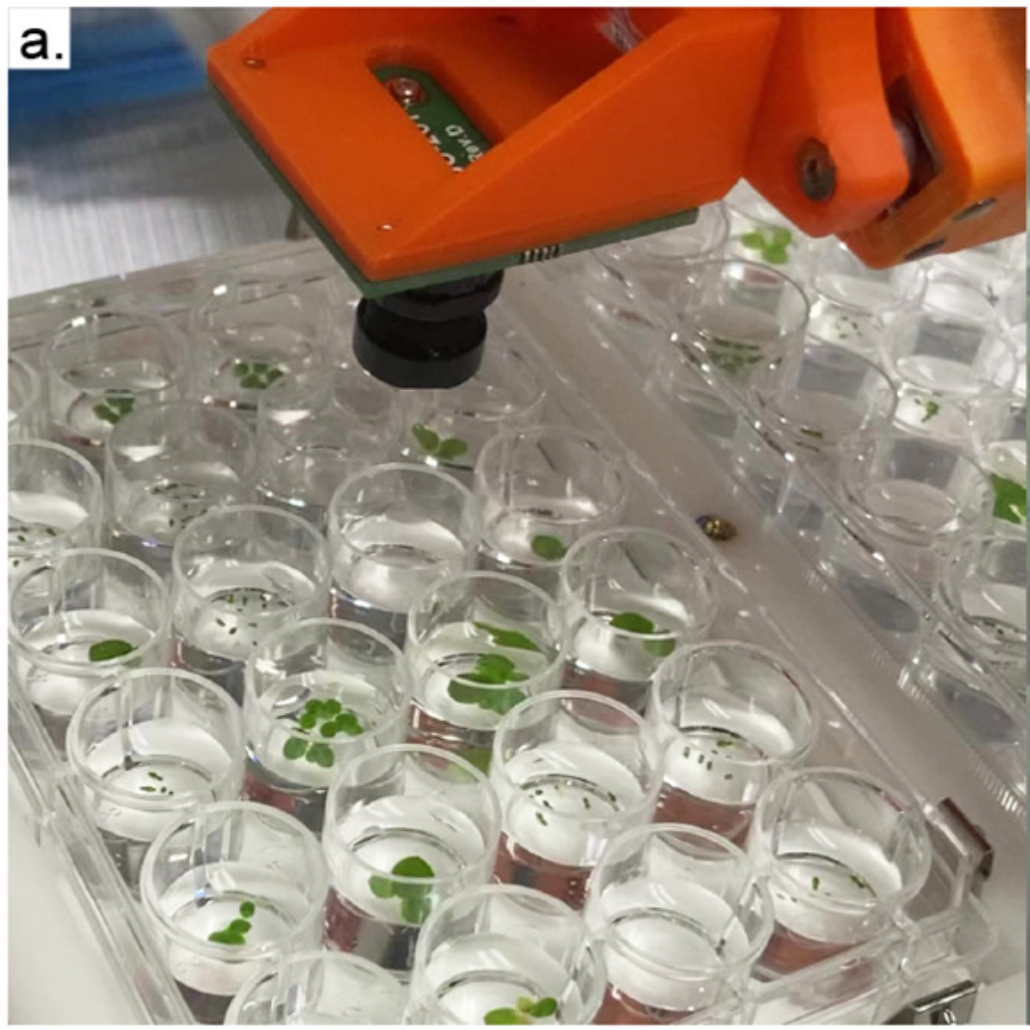

Subbaraman, Blair, et al. "The Duckbot: A system for automated imaging and manipulation of

duckweed." Plos one 19.1 (2024): e0296717.

Strieth-Kalthoff, Felix, et al. "Delocalized, asynchronous, closed-loop discovery of organic

laser emitters." Science 384.6697 (2024): eadk9227.

From The

Economist

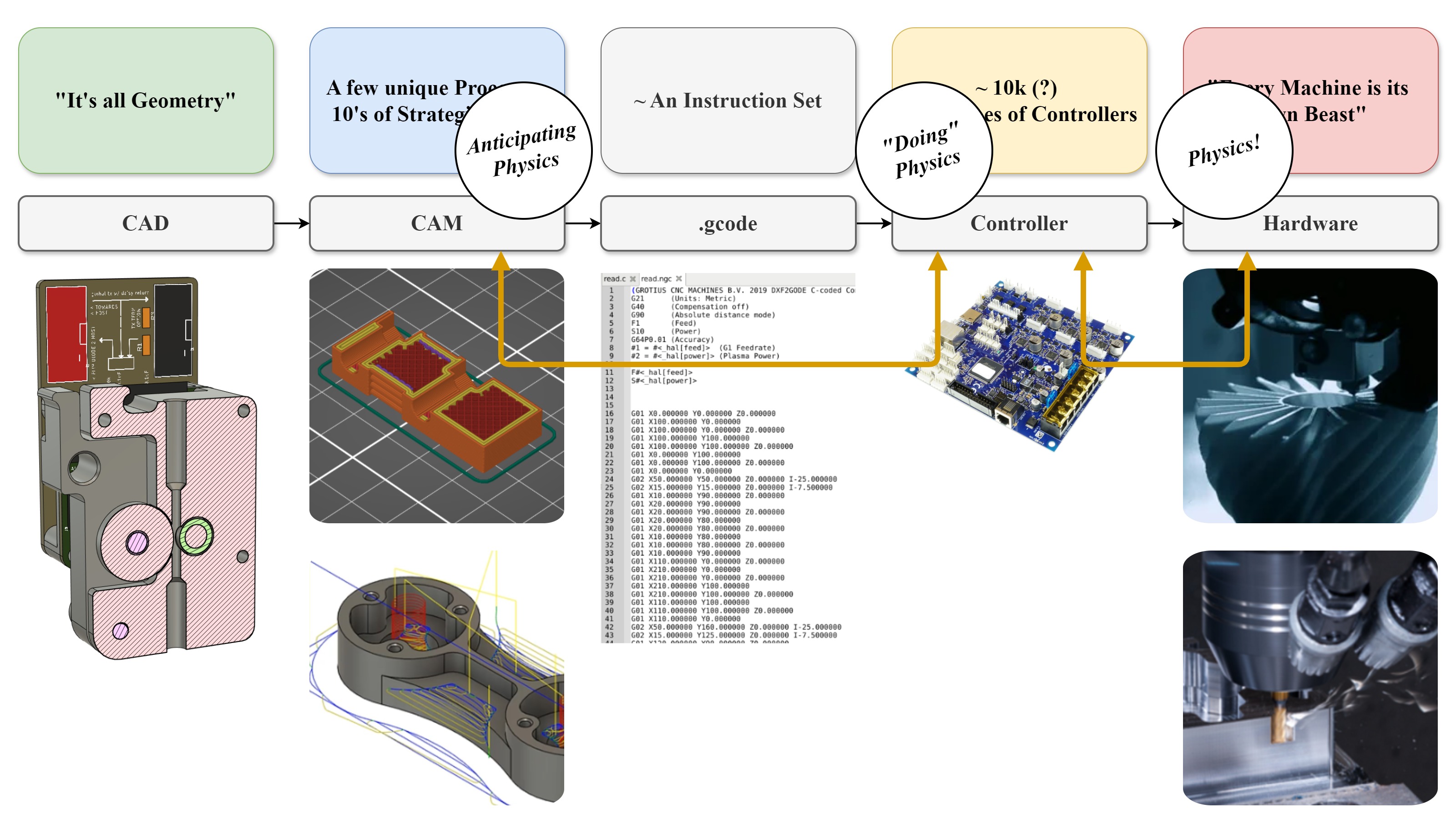

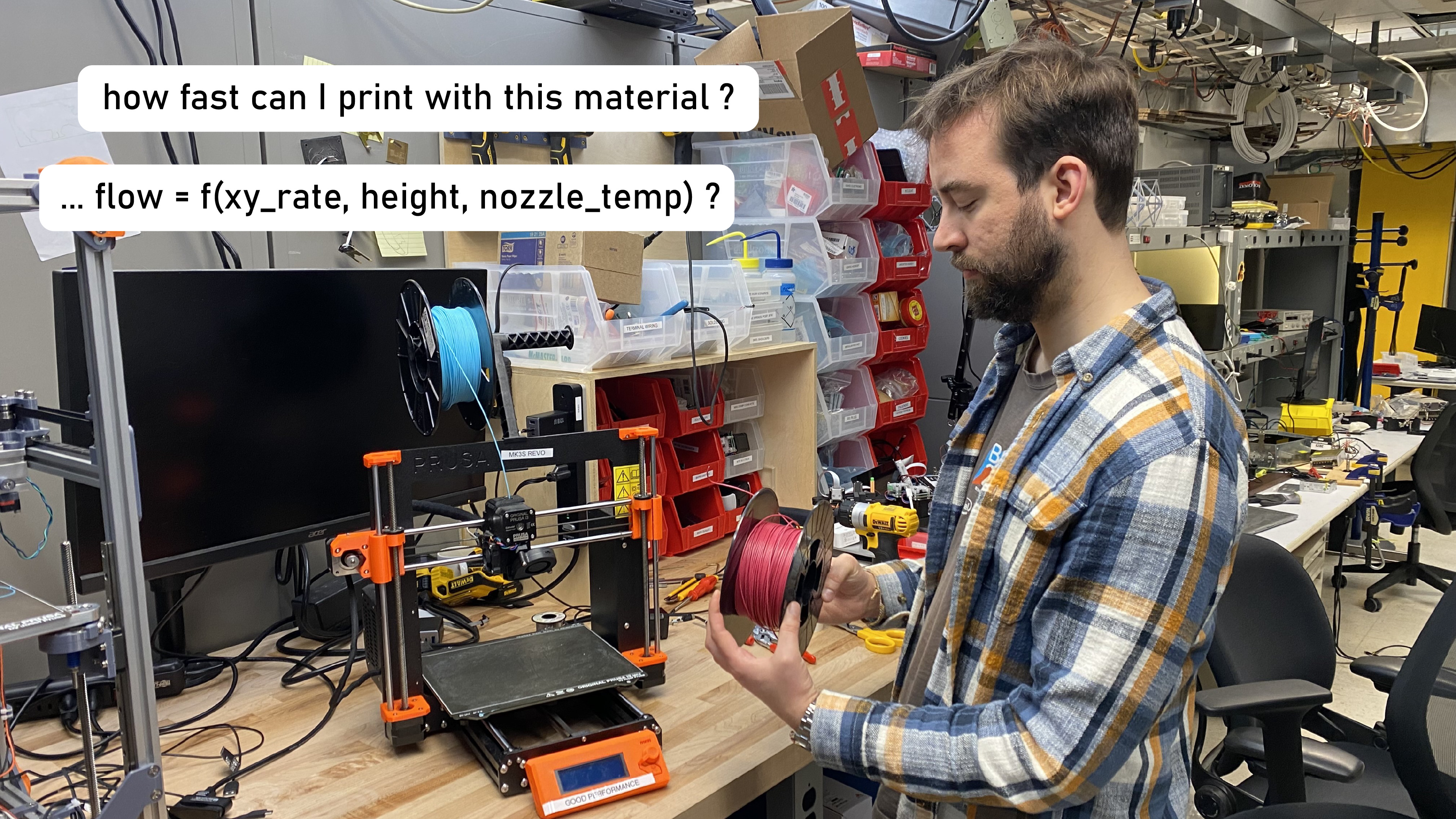

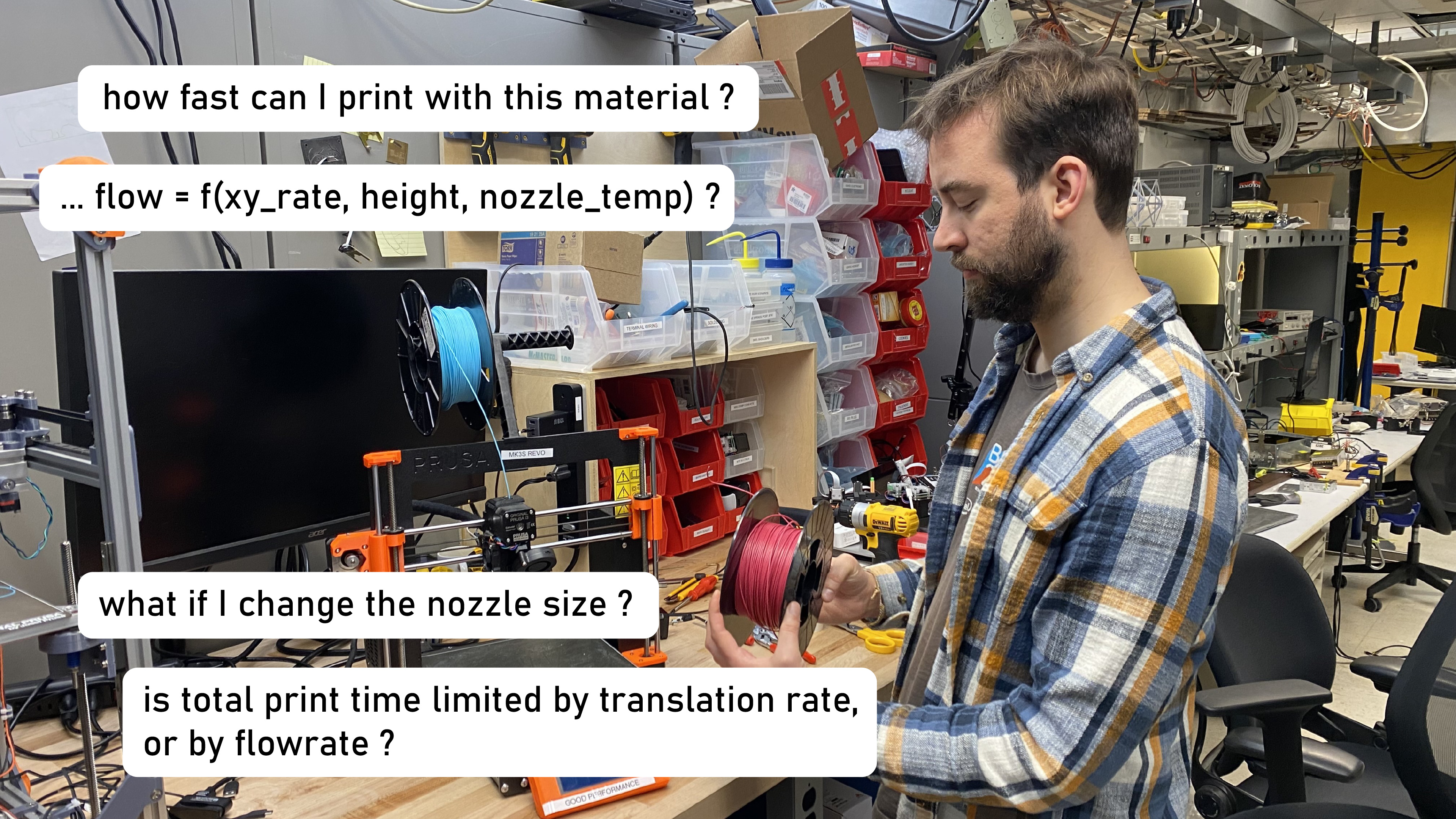

Nor can we improve those jobs' productivity; we aren't developing new automation rapidly

enough.

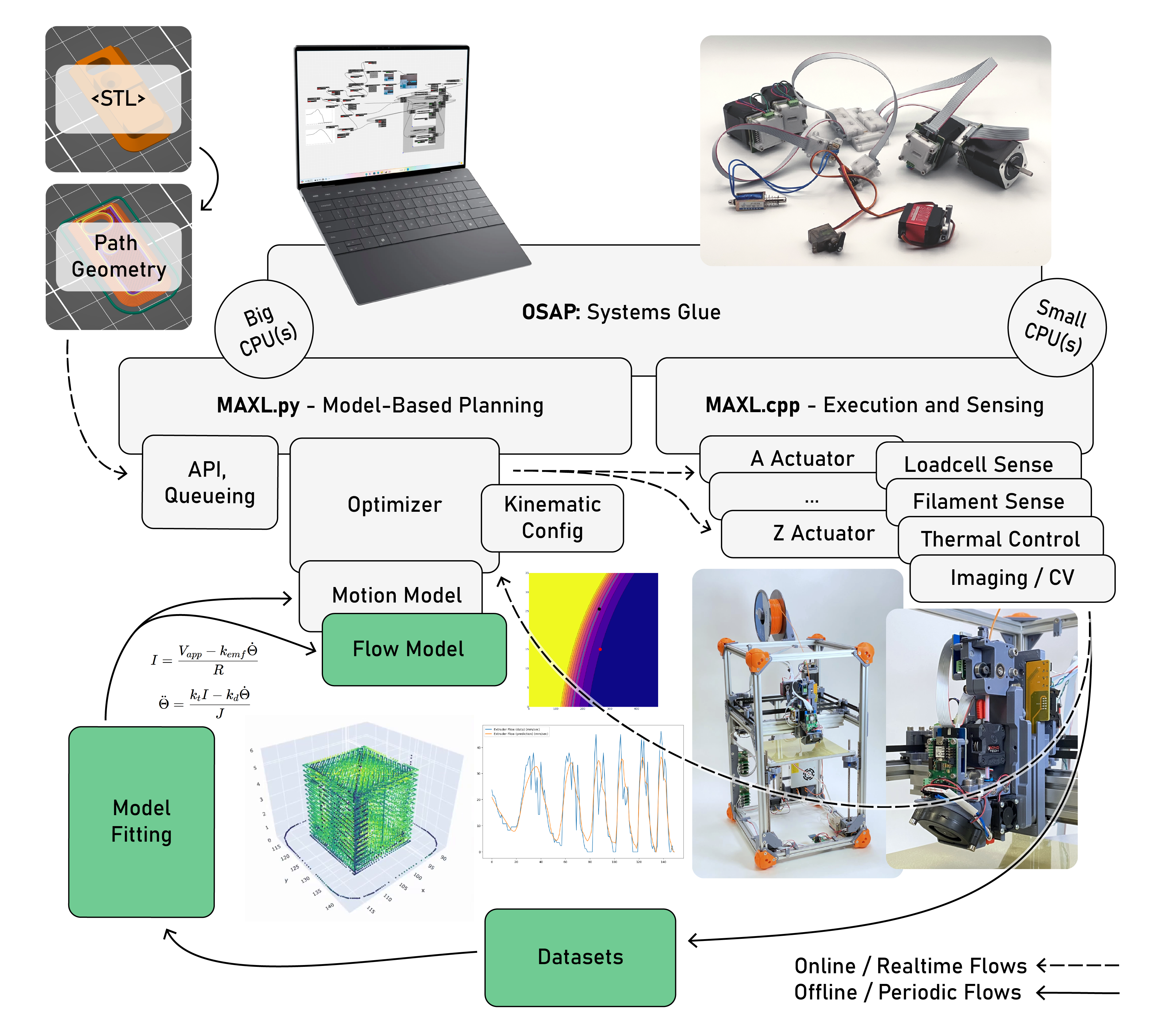

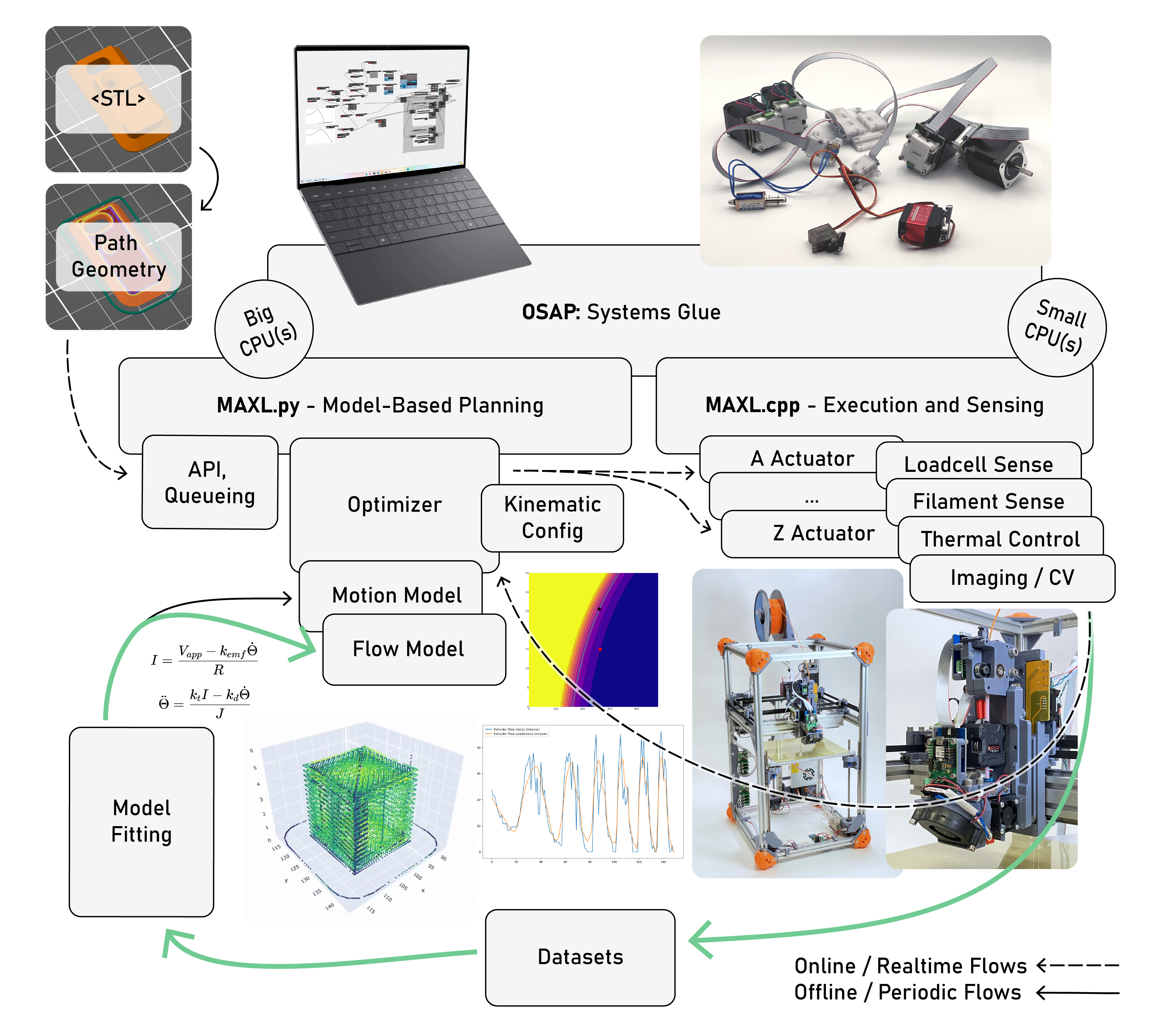

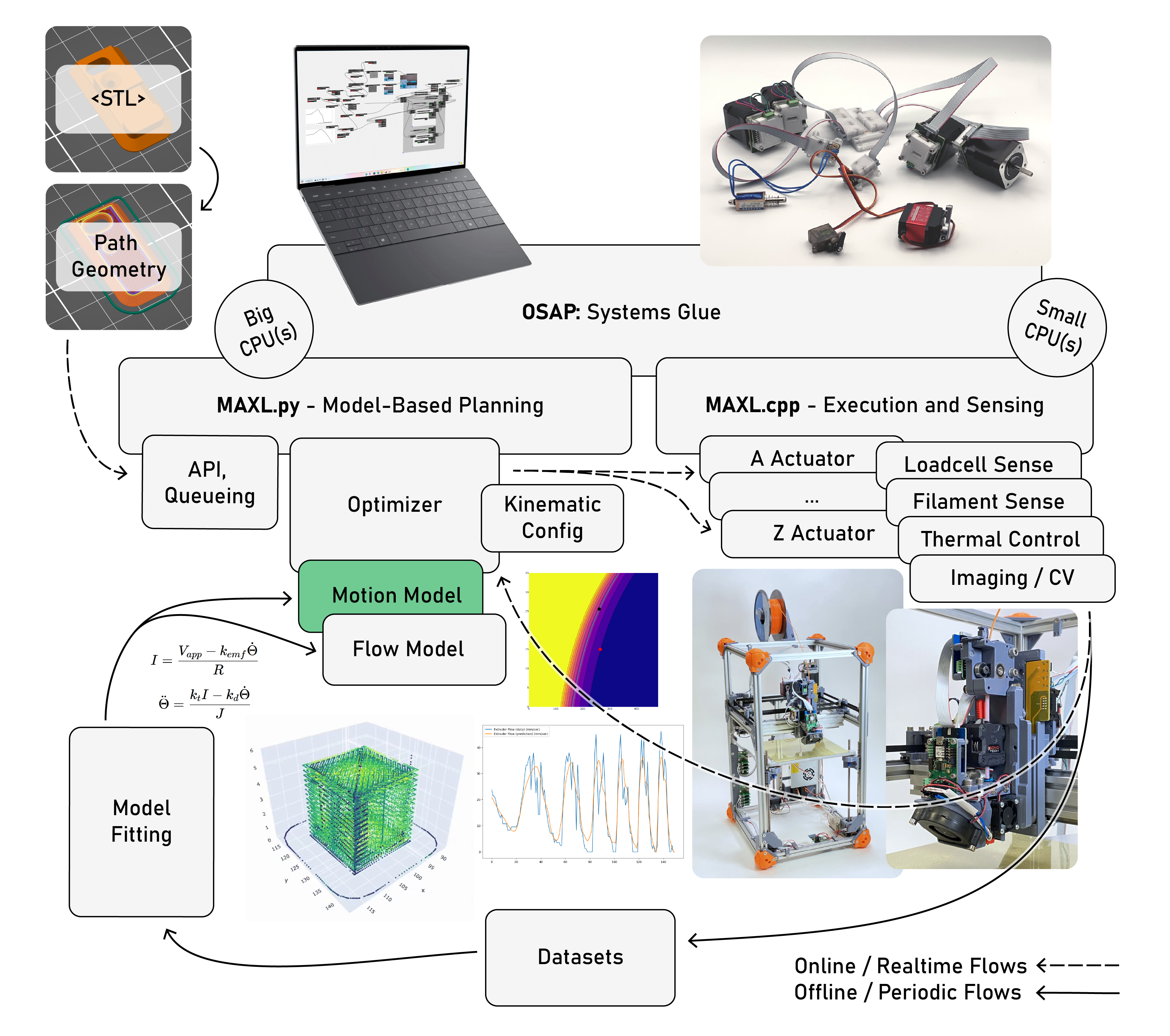

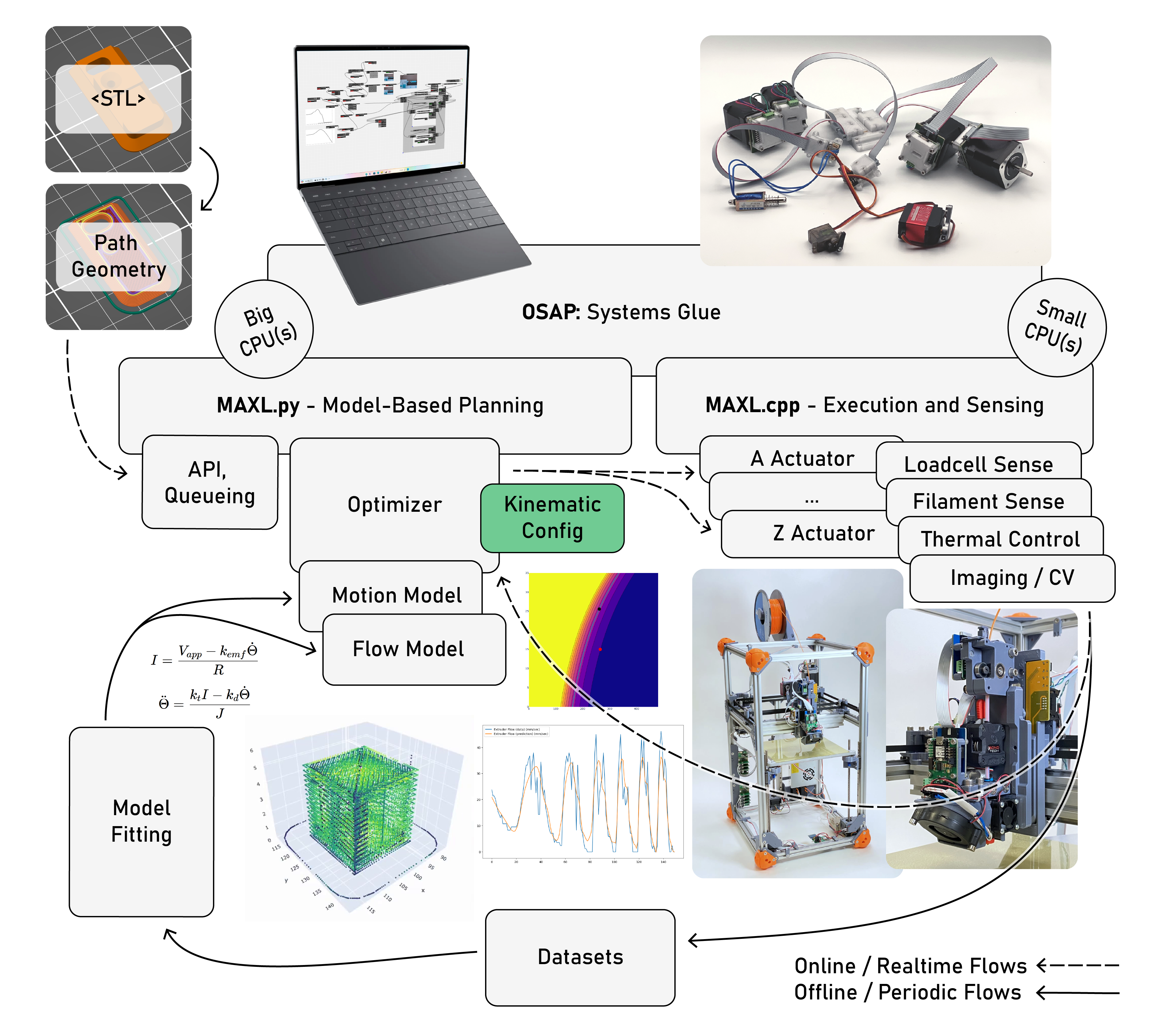

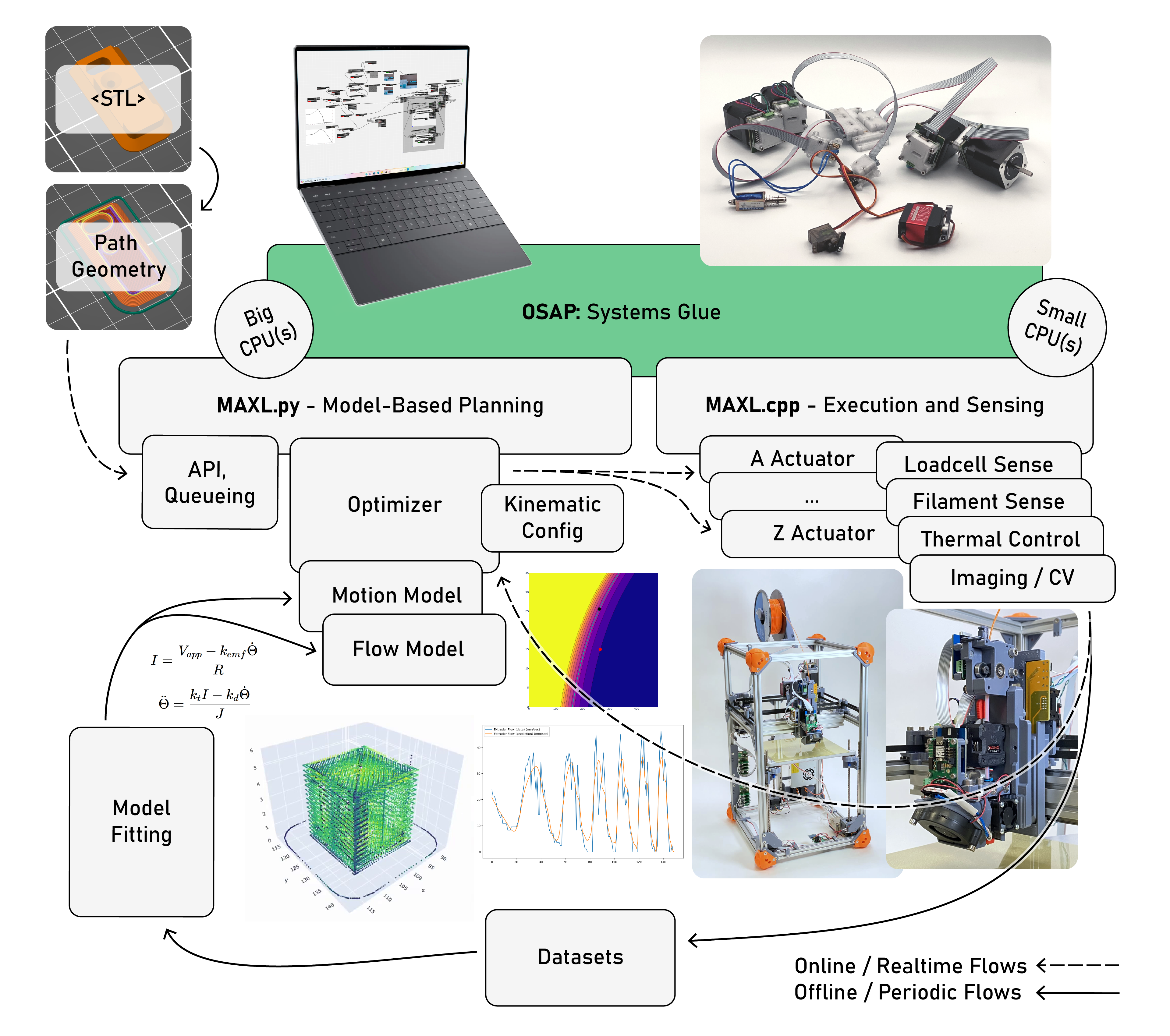

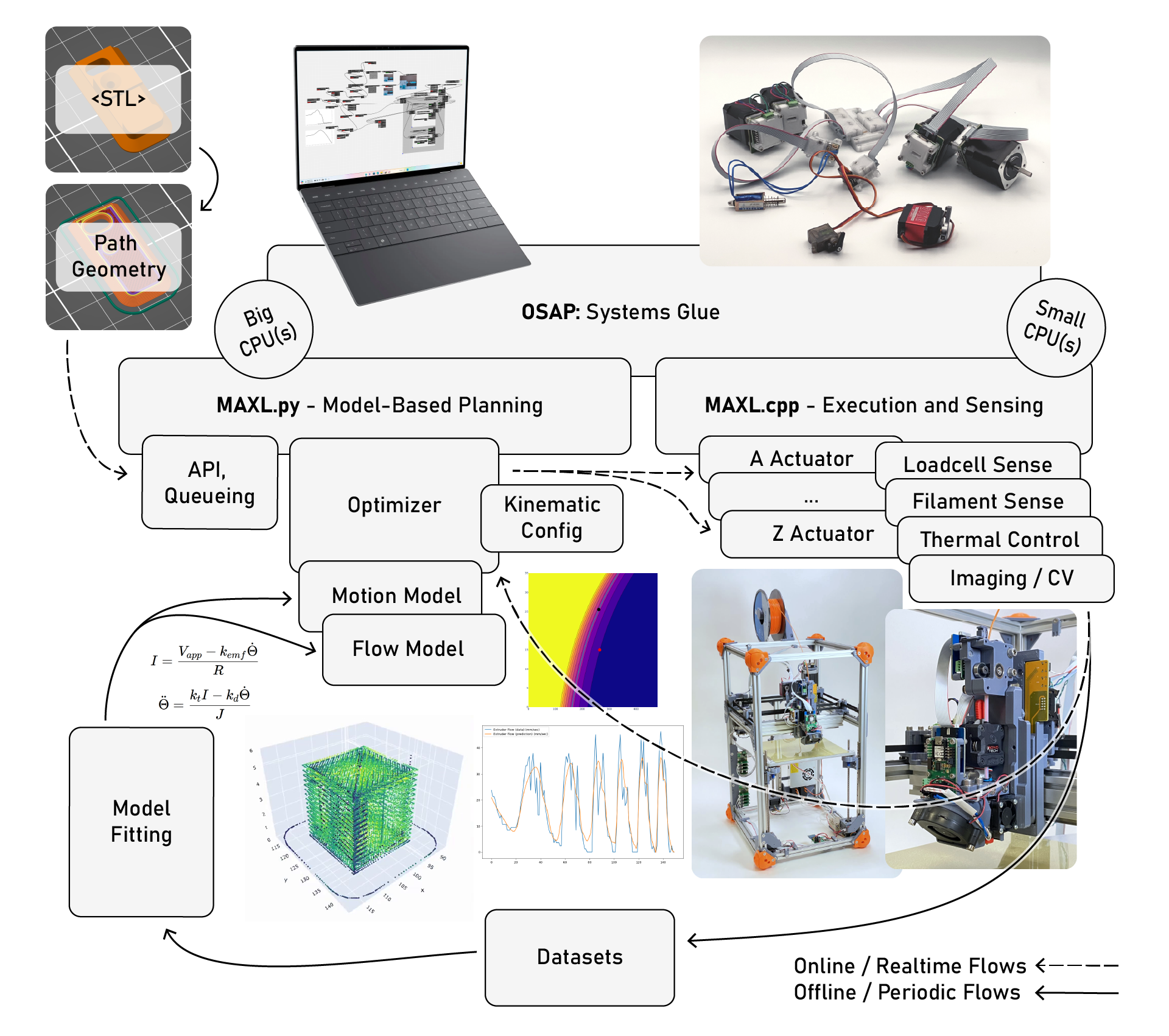

Proposing to replace...

Best-guess, iterative parameter tuning.

With...

Models of machine physics generated with in-situ data.

Guarantee that we don't exceed physical limits.

Improve performance by operating close to those limits.

A more intuitive tool for users to understand their equipment.

With...

Modular distributed controllers based on feedback.

Span multiple layers of configuration and control.

Generate as much data as they consume.

Interface to digital twins.

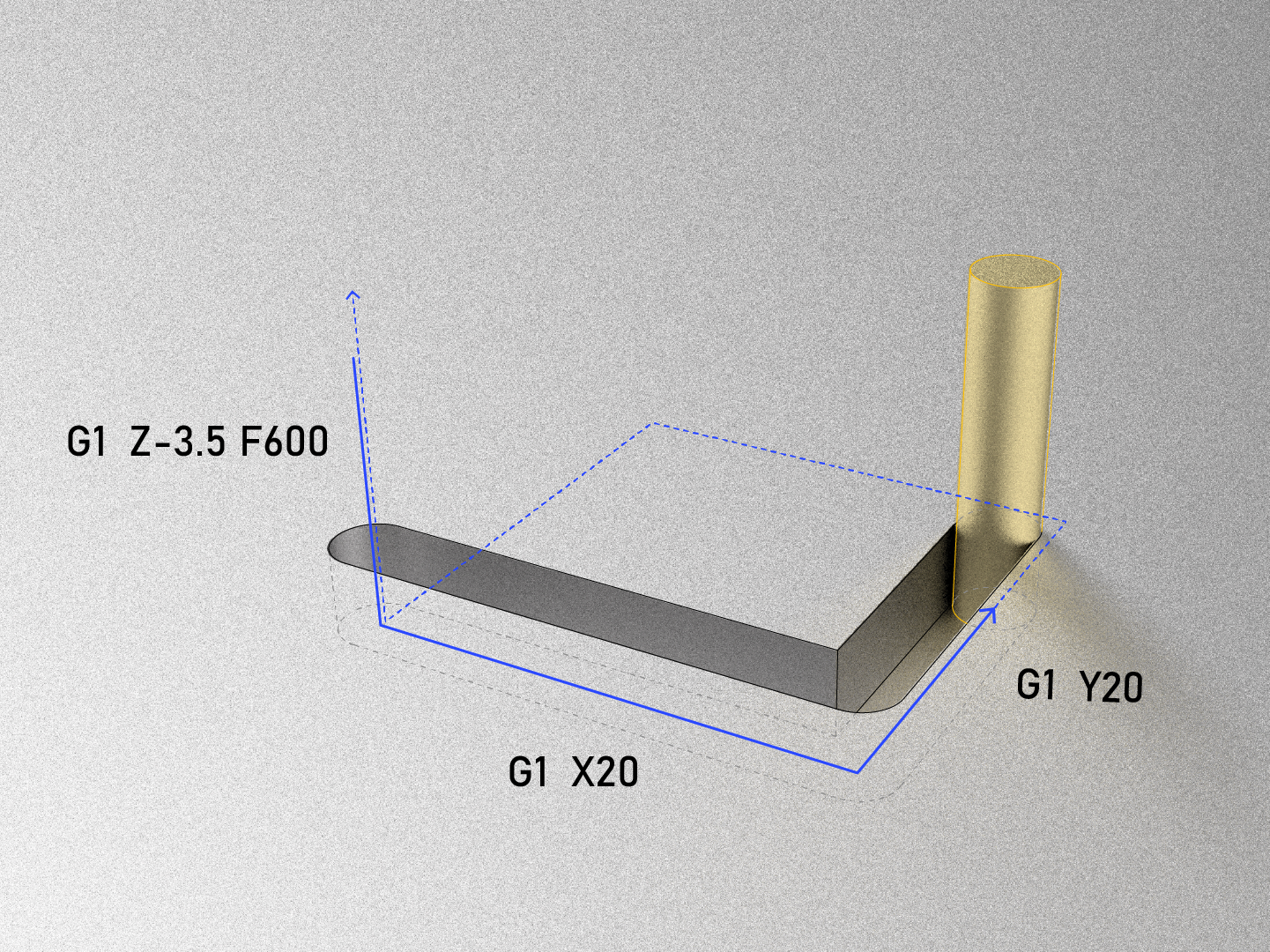

G21 ; use millimeters

G28 ; run the homing routine

G92 X110 Y120 Z30 ; set current position to (110, 120, 30)

G0 X10 Y10 Z10 F6000 ; "rapid" in *units per minute*

M3 S5000 ; turn the spindle on, at 5000 RPM

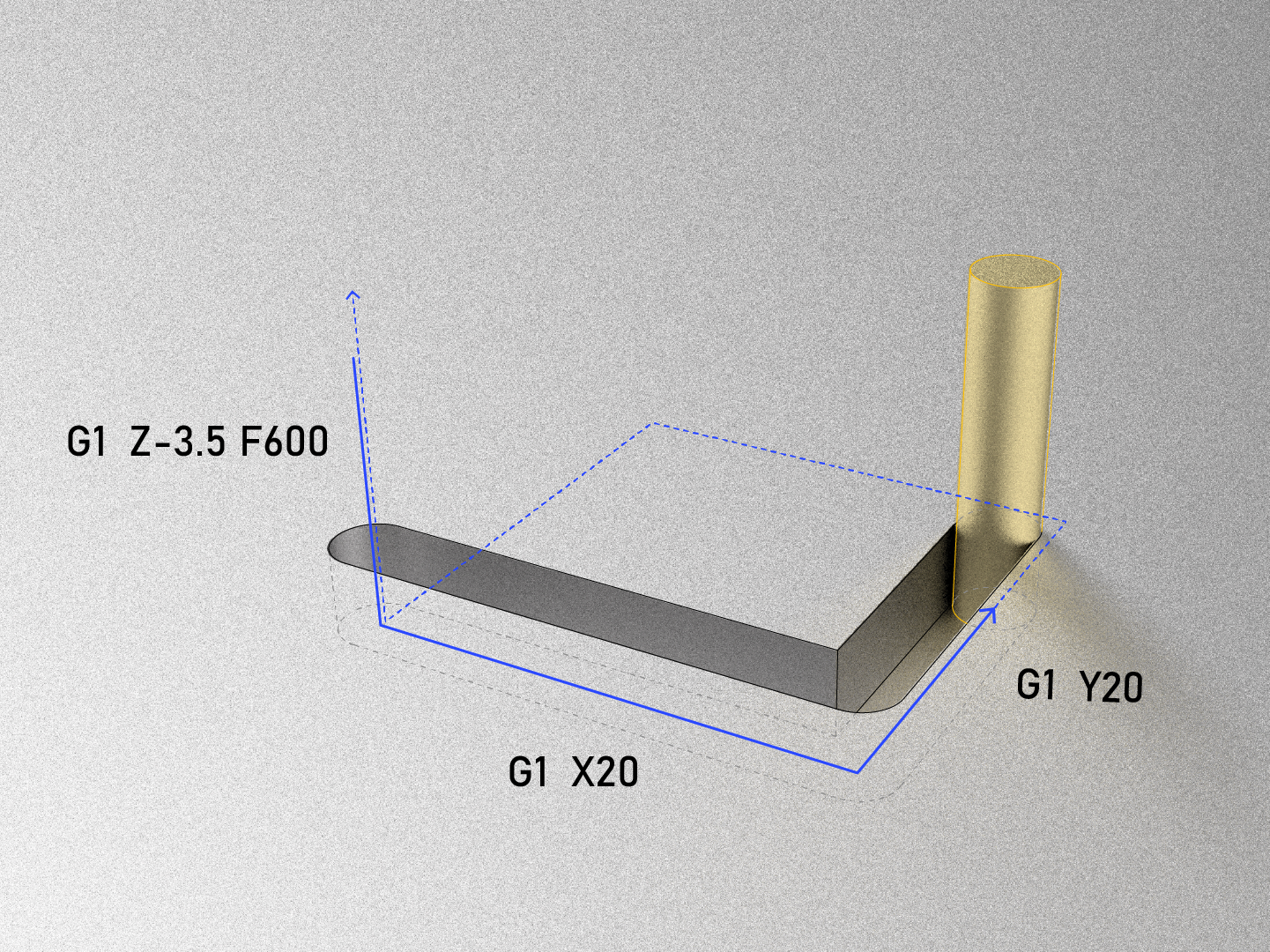

G1 Z-3.5 F600 ; plunge from (10, 10, 10) to (10, 10, -3.5)

G1 X20 ; draw a square, go to the right,

G1 Y20 ; go backwards 10mm

G1 X10 ; go to the left 10mm

G1 Y10 ; go forwards 10mm

G1 Z10 ; go up to Z10, exiting the material

M5 ; stop the spindle

G0 X110 Y120 Z30 ; return to the position after homing (at 6000)

A simple GCode program, for a milling machine.

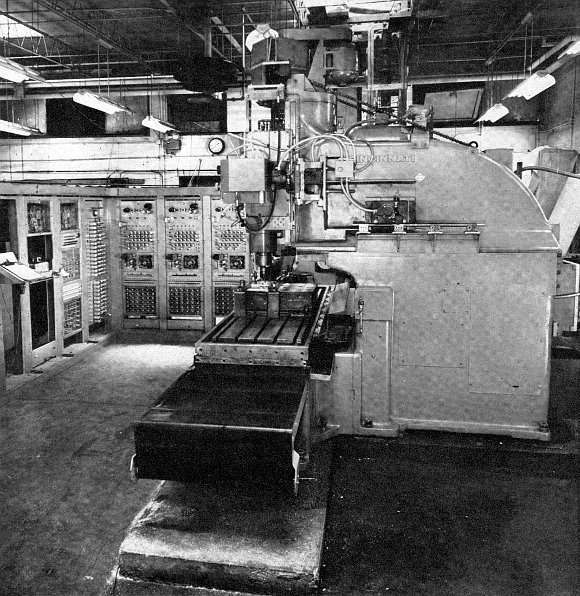

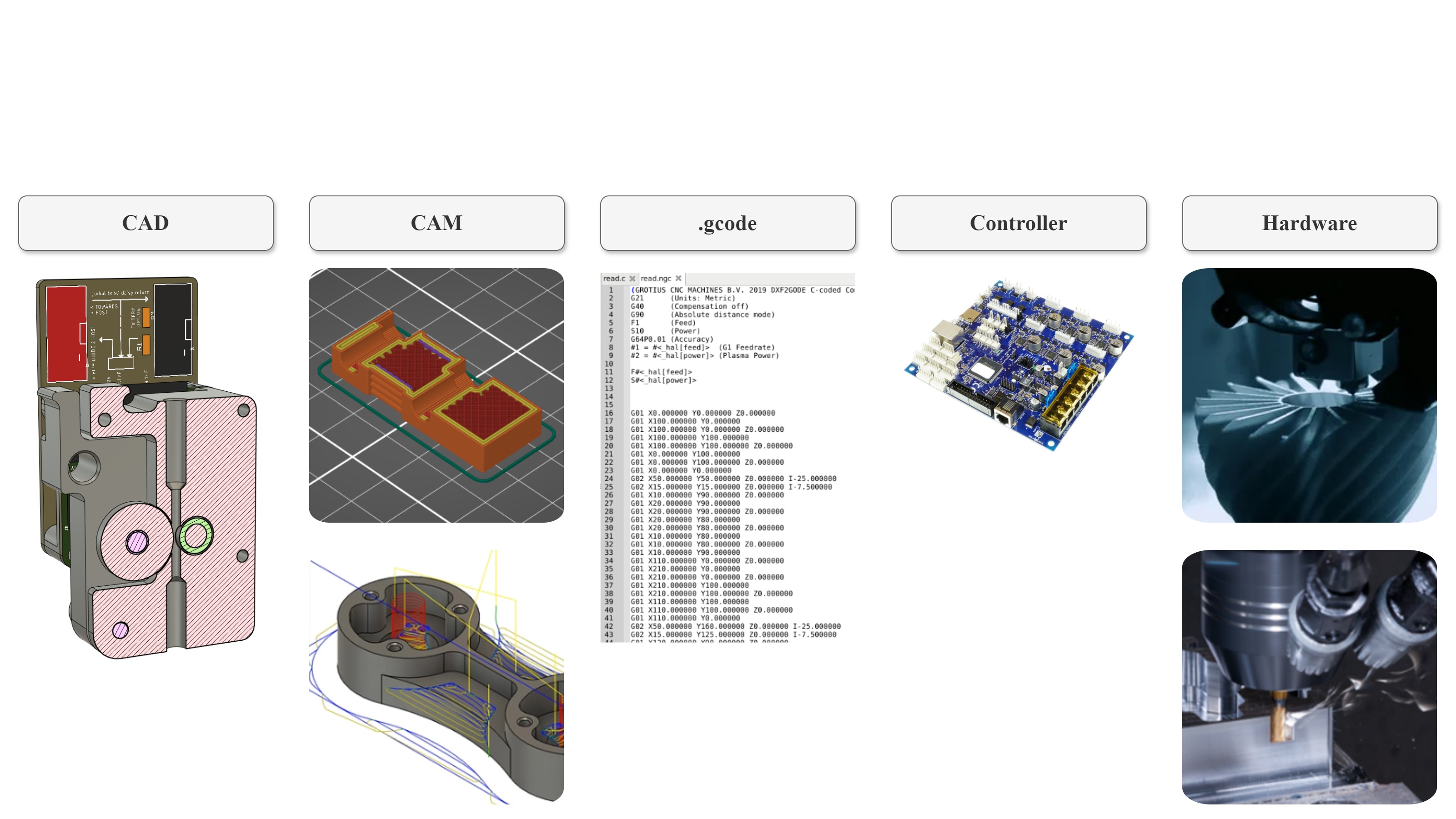

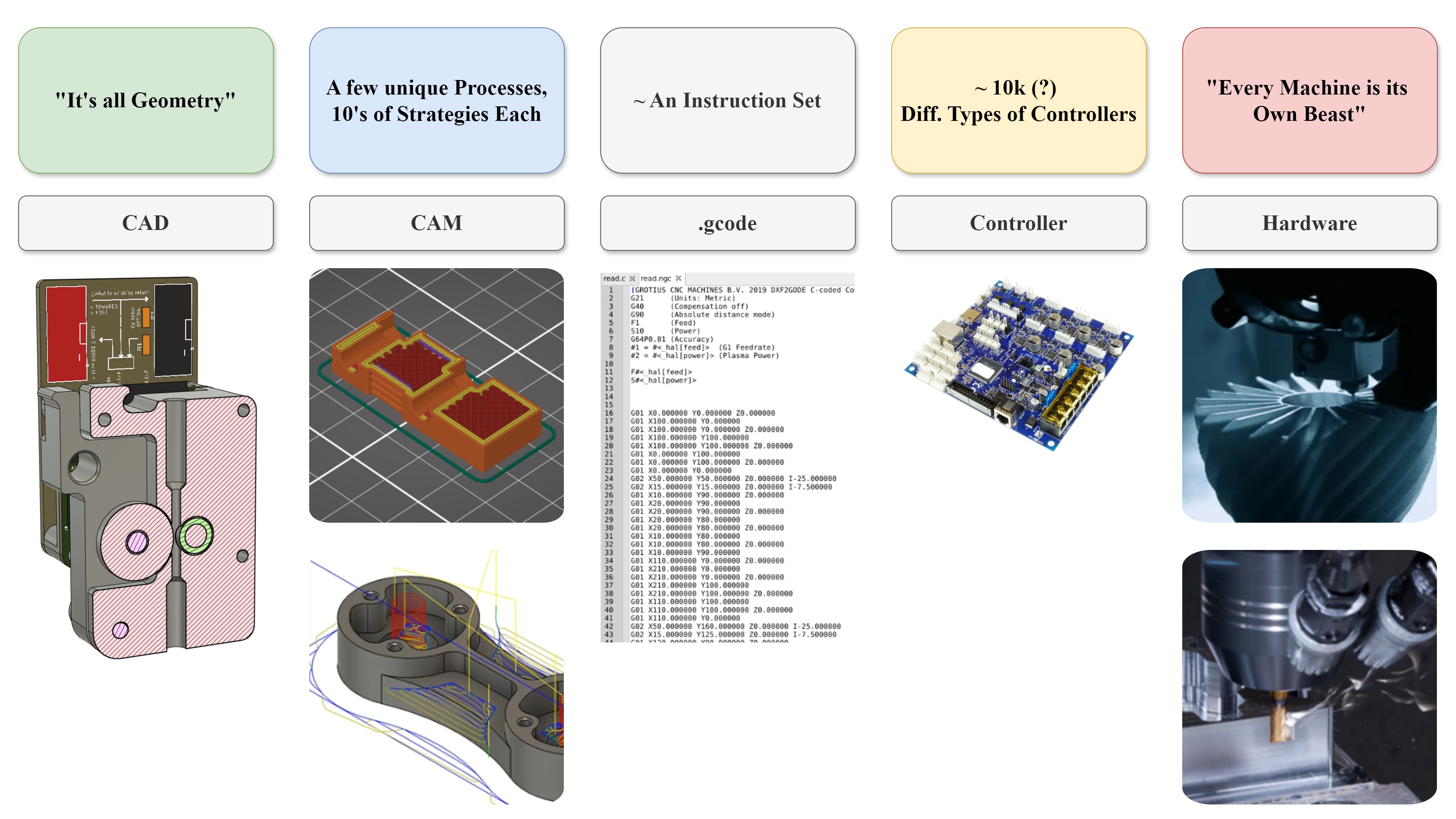

GCode was invented alongside the first CNC machine, in a milieu of computer scientists who were

developing top-down, feed-forward design patterns for system abstraction.

Noble, David. Forces of production: A social history of industrial automation. Routledge, 2017.

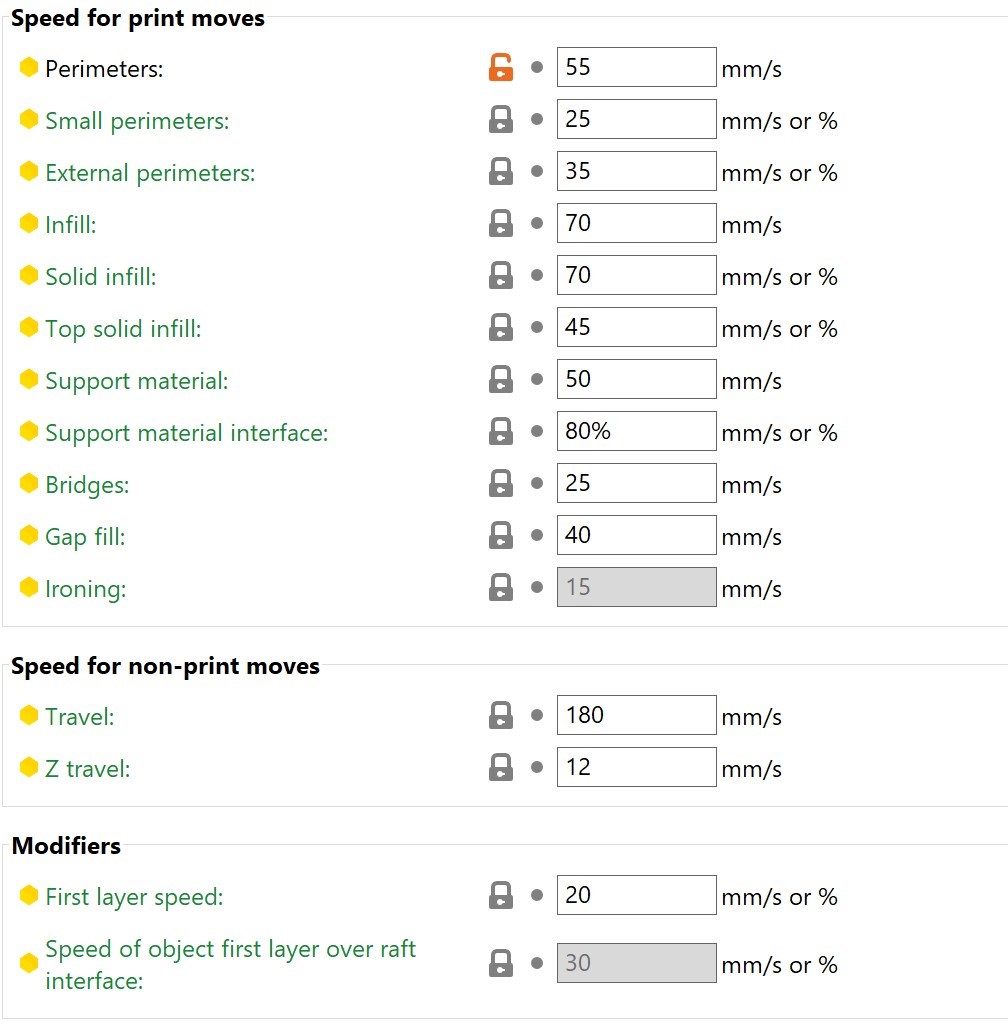

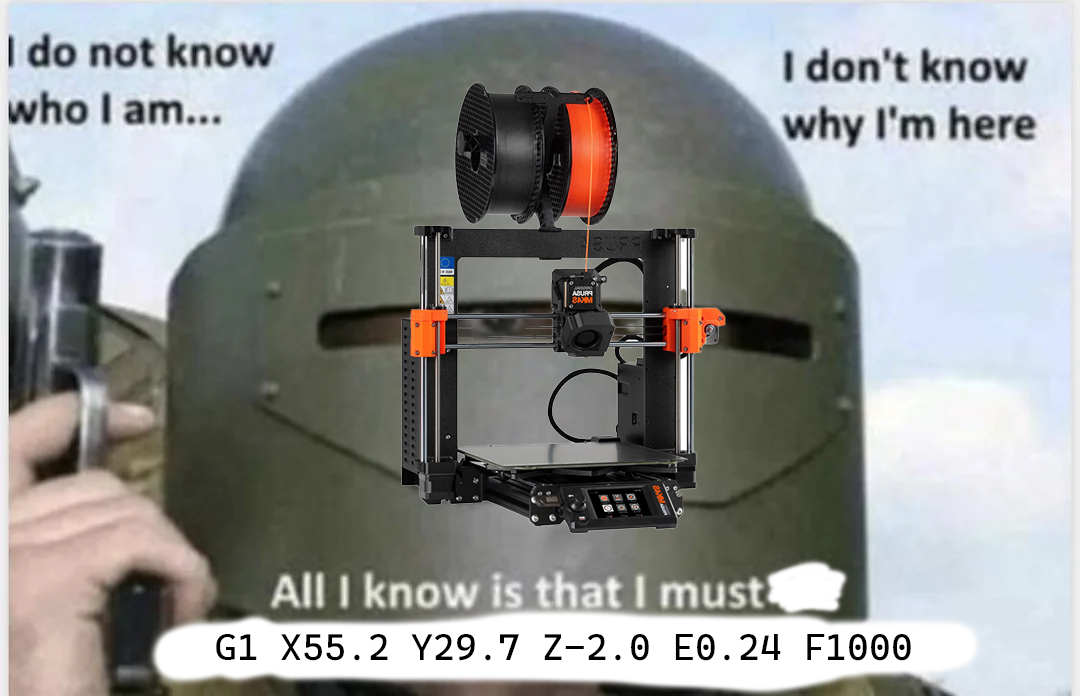

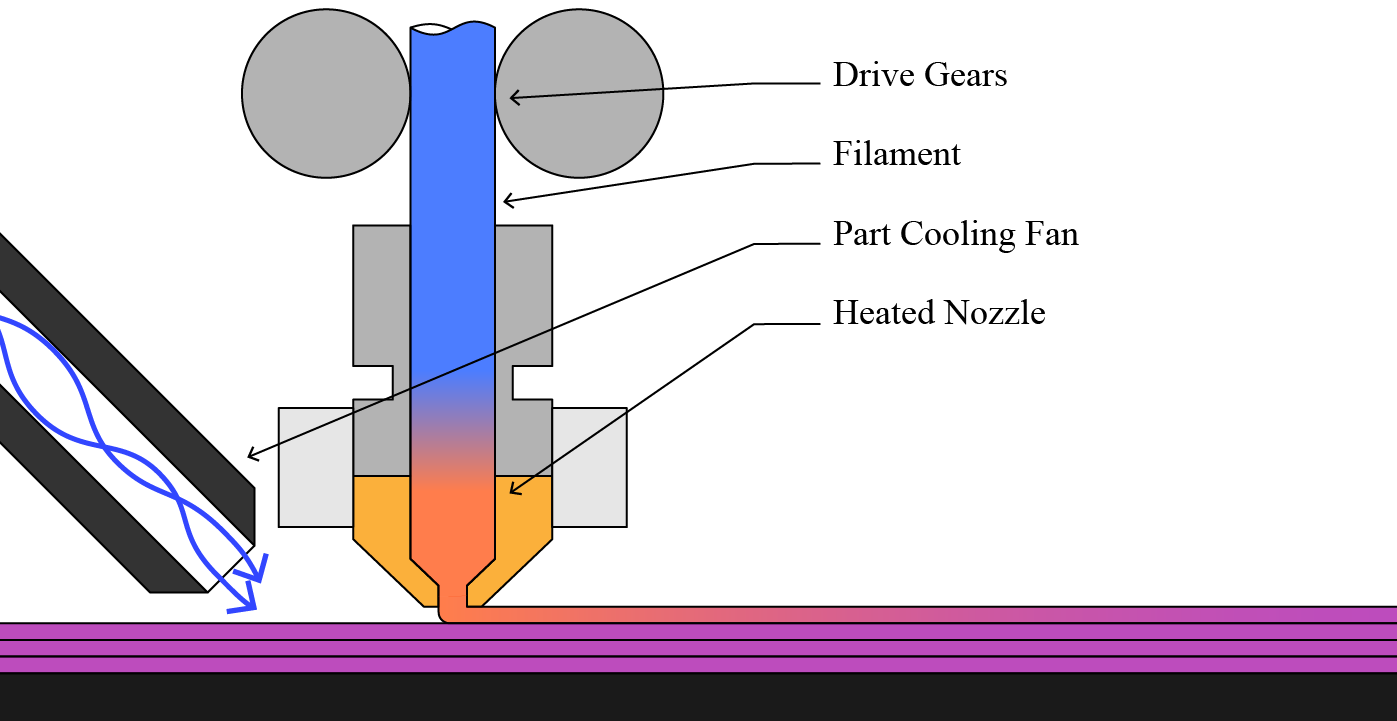

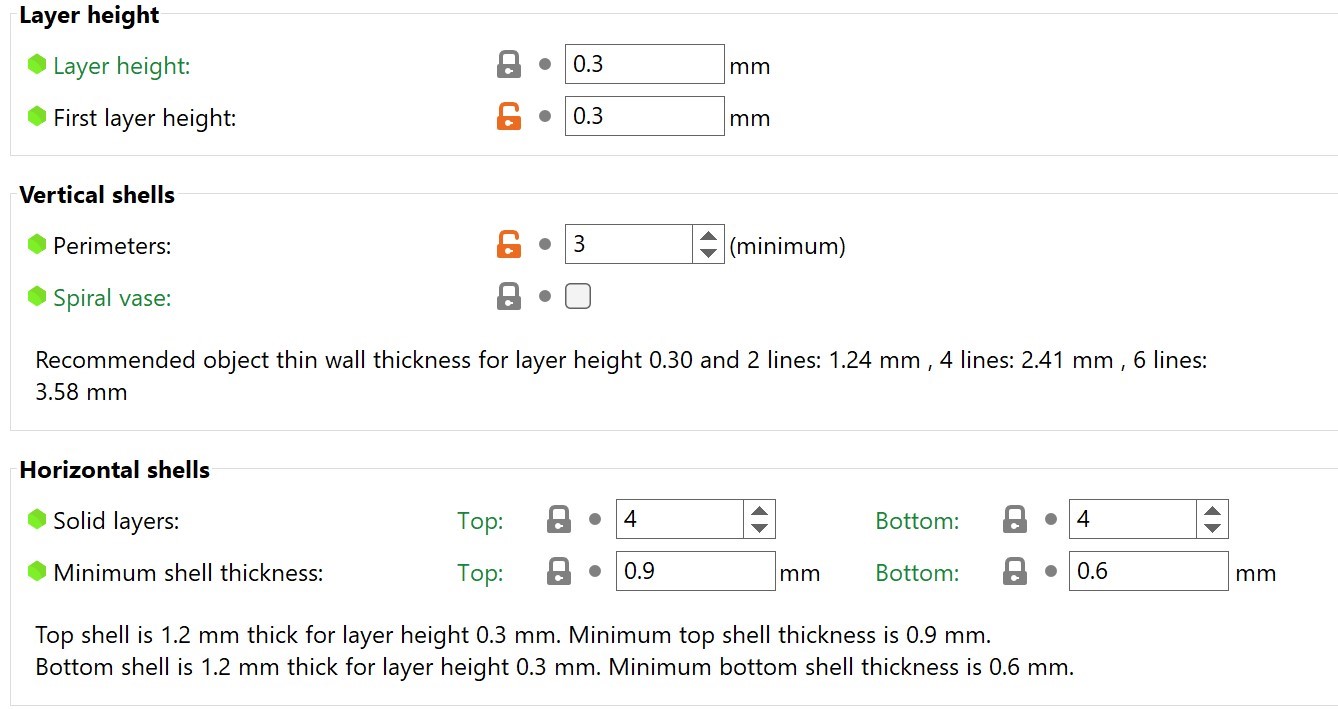

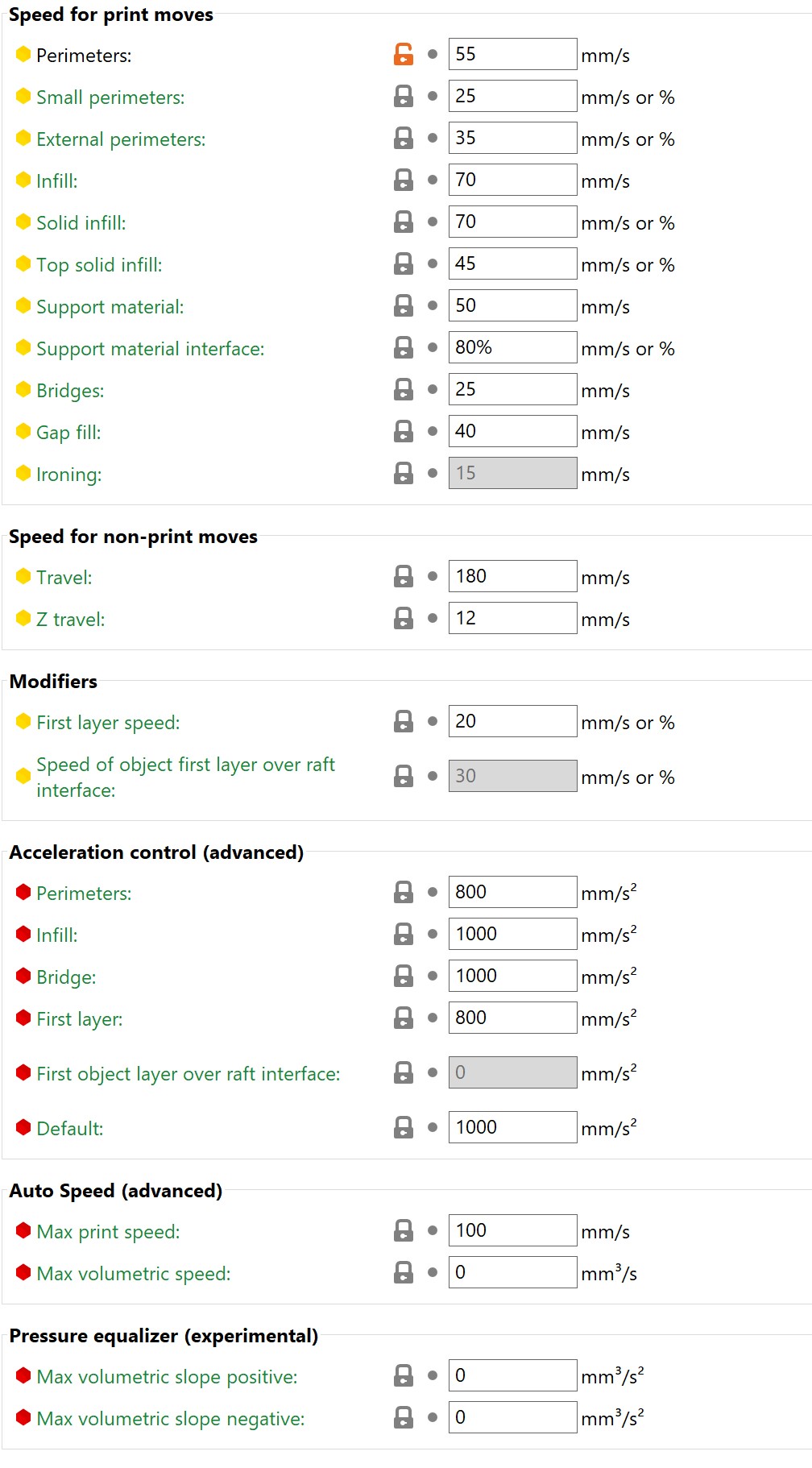

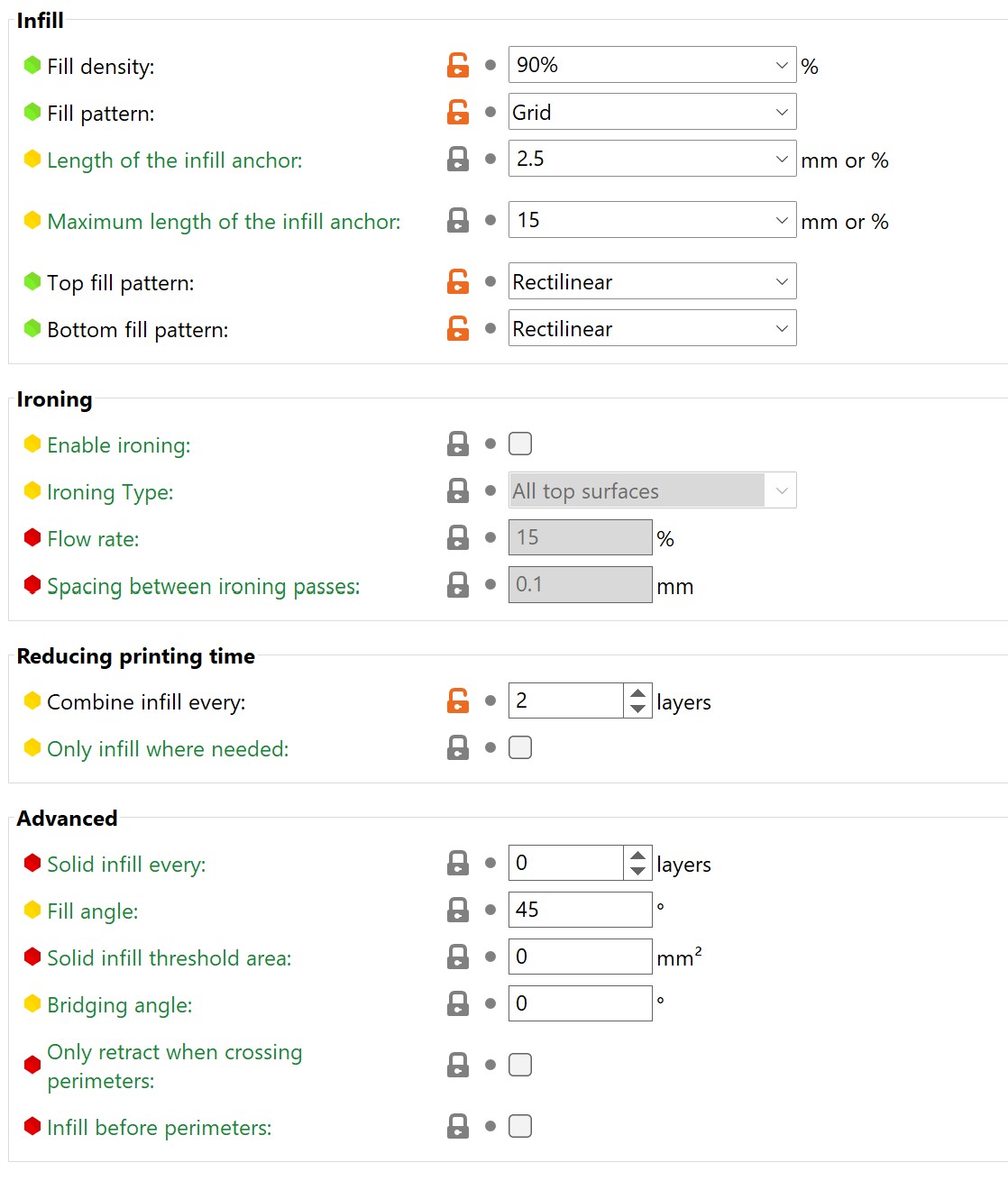

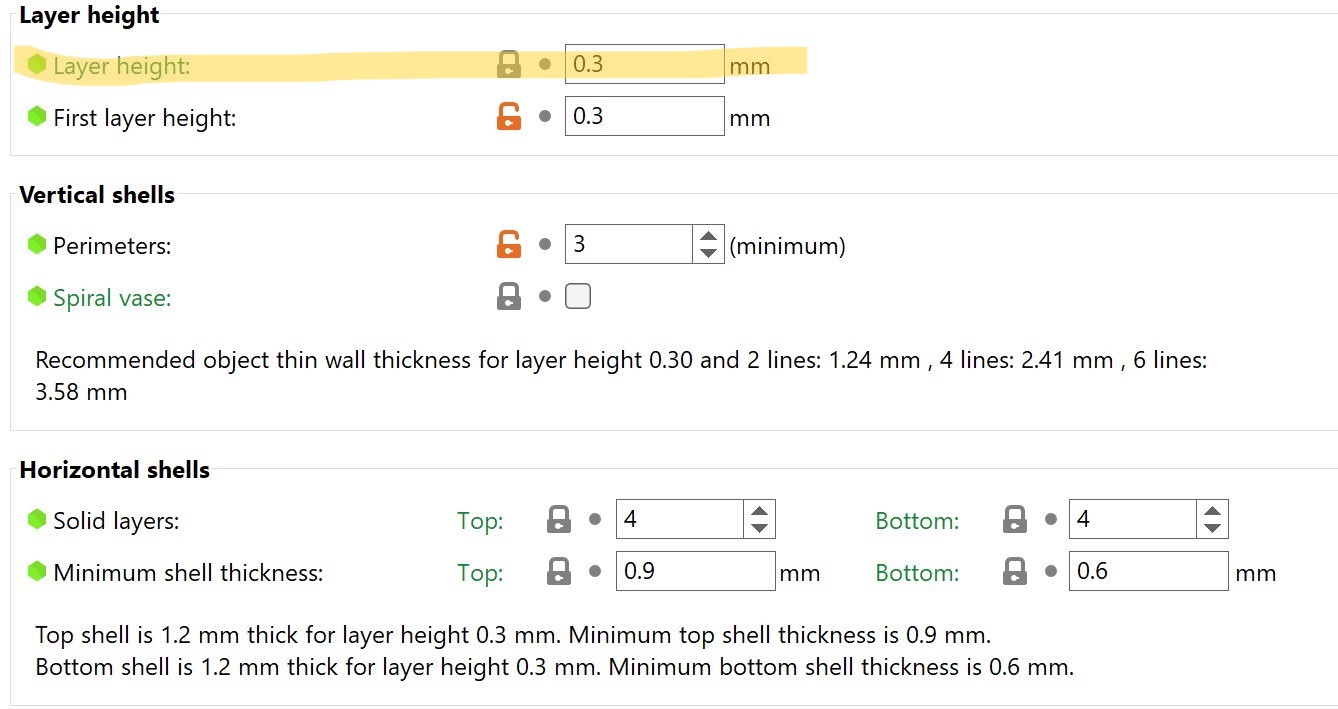

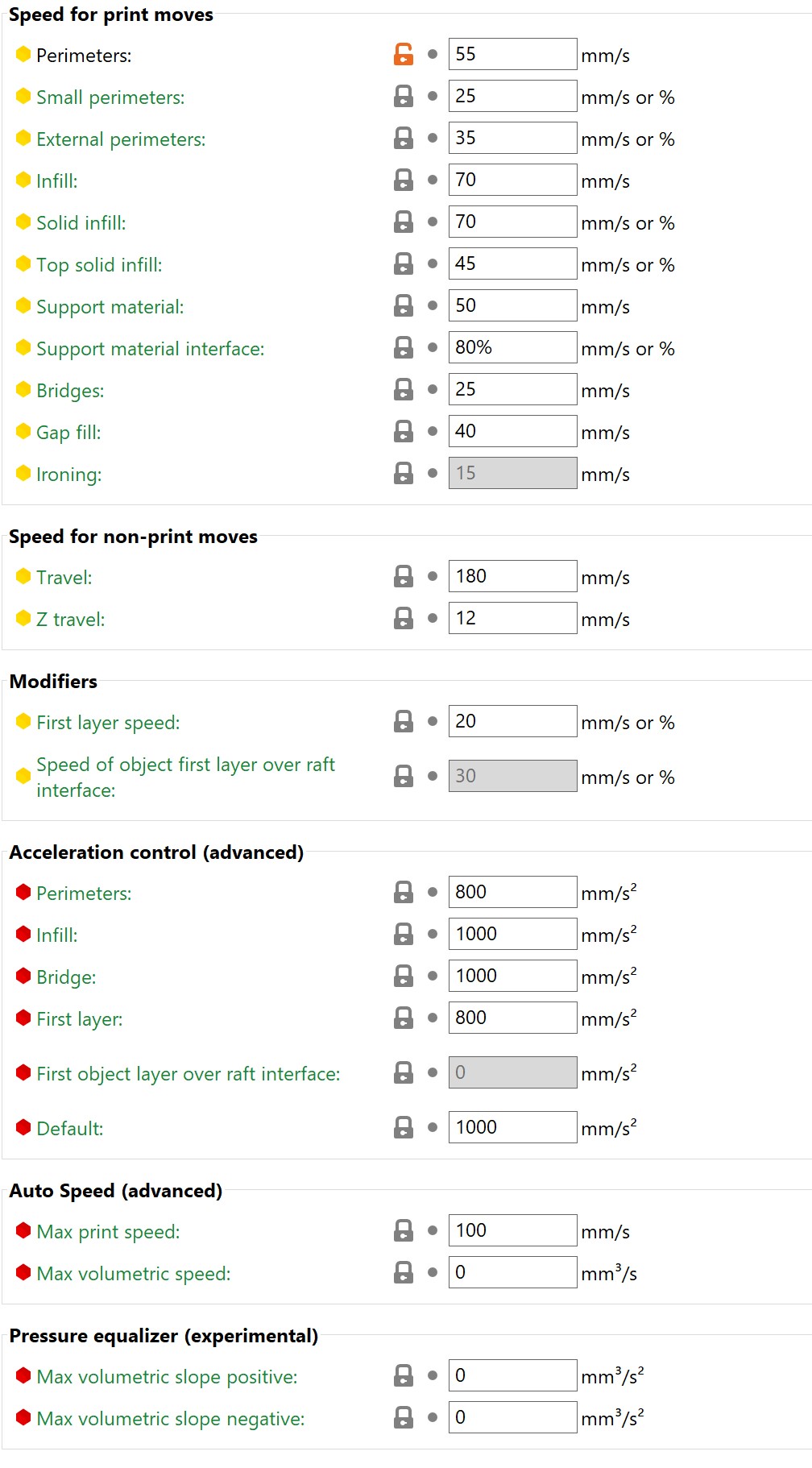

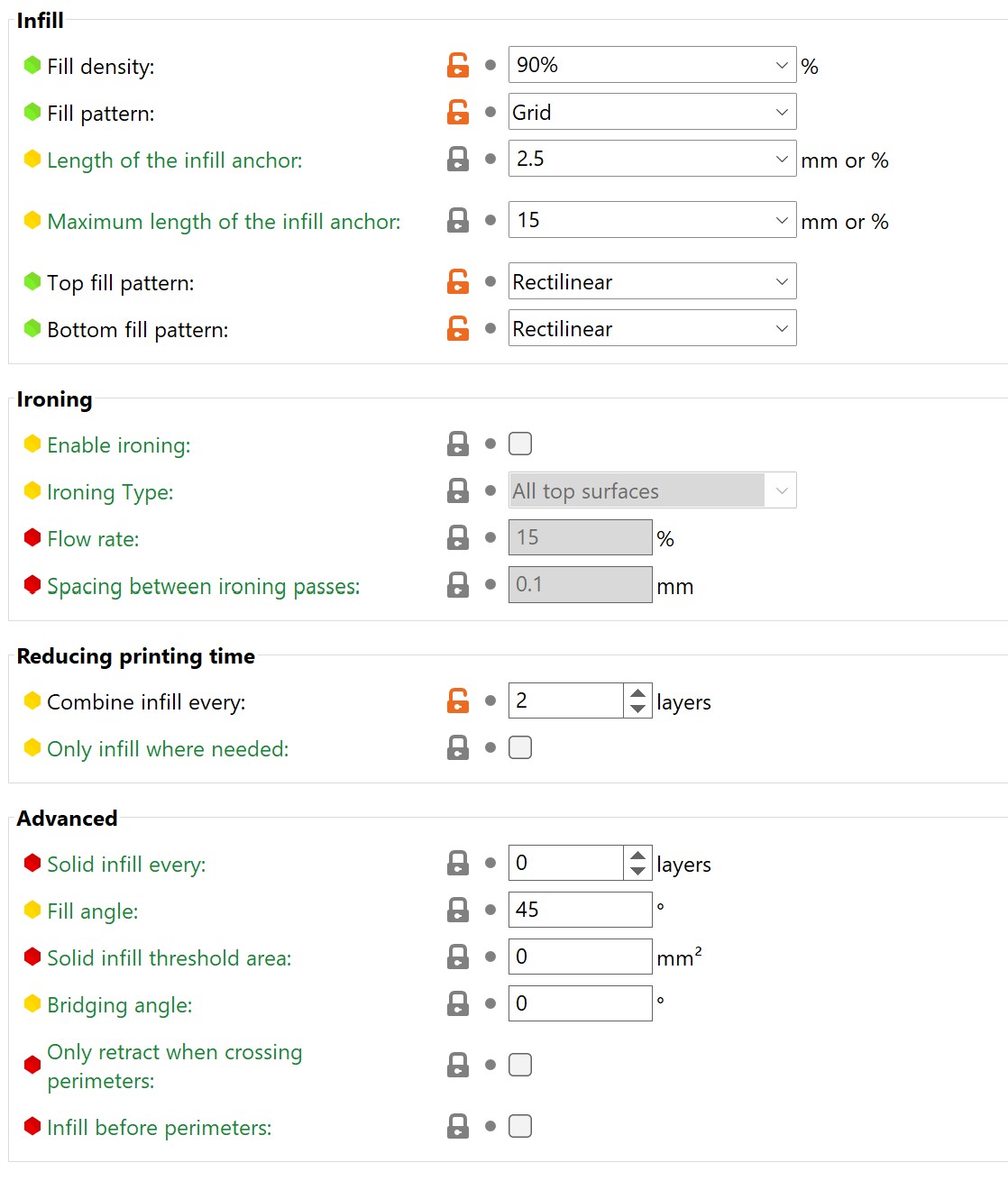

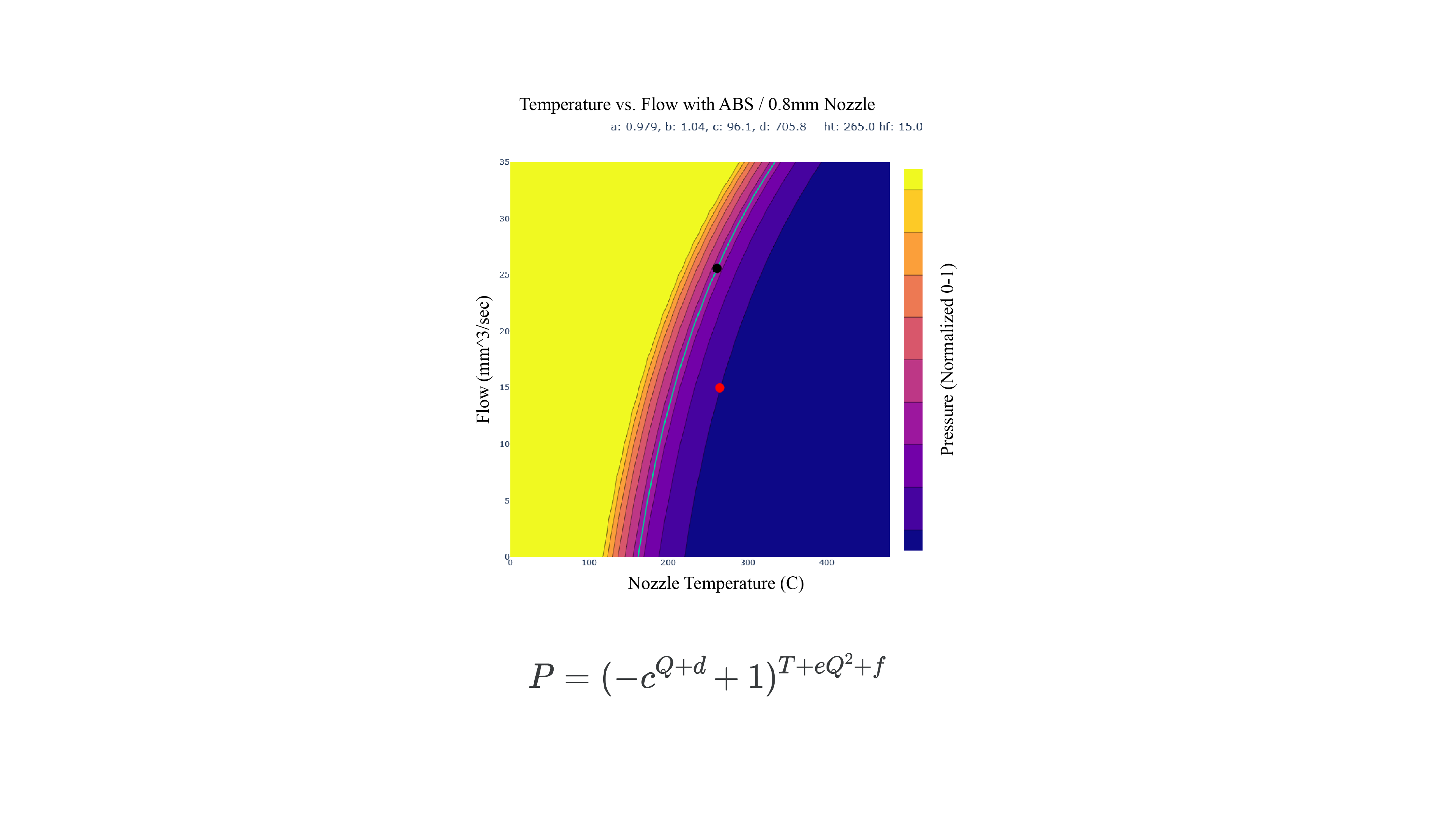

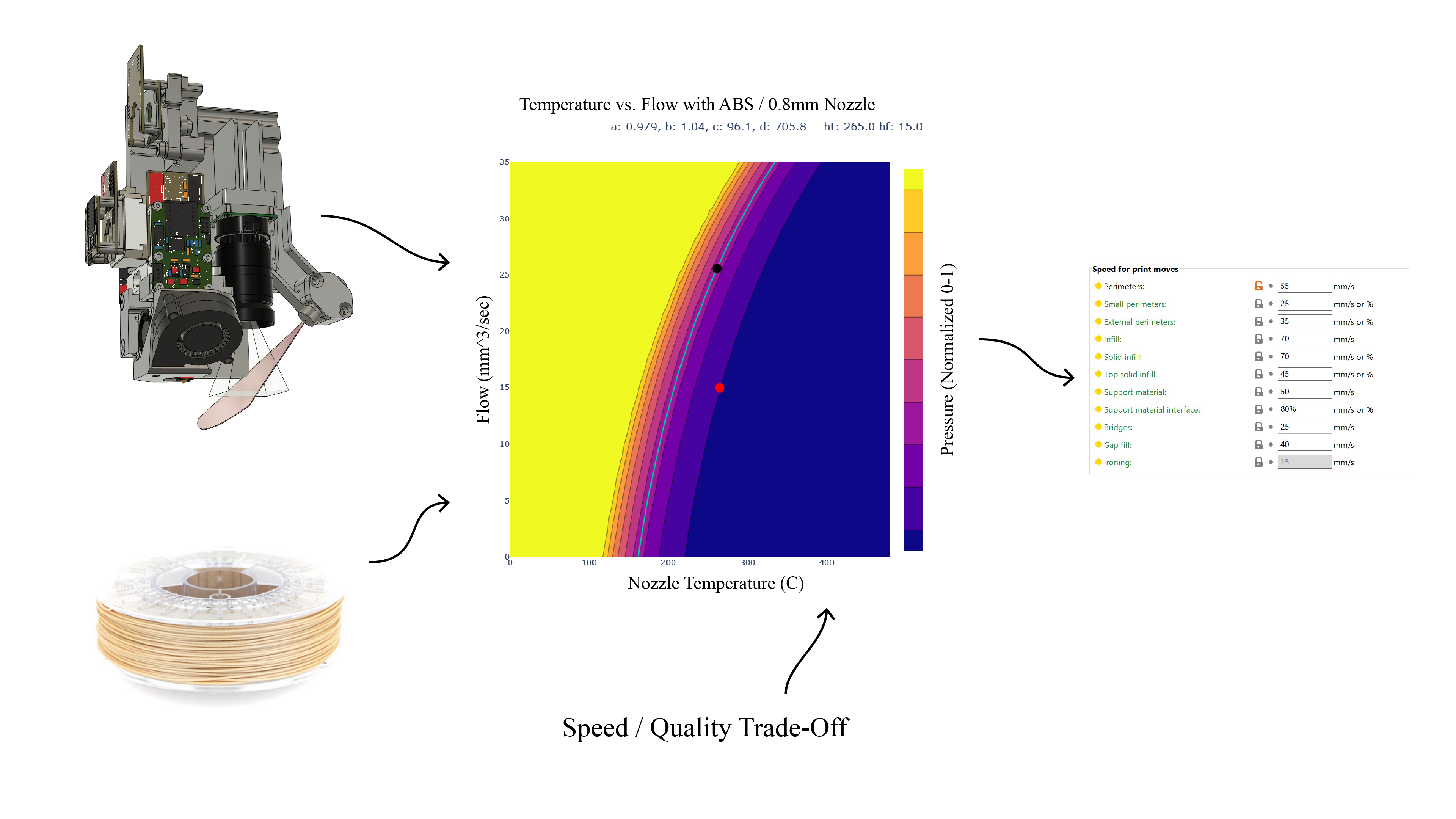

3D Printing Parameters as shown to users in PrusaSlicer

3D Printing Parameters as shown to users in PrusaSlicer

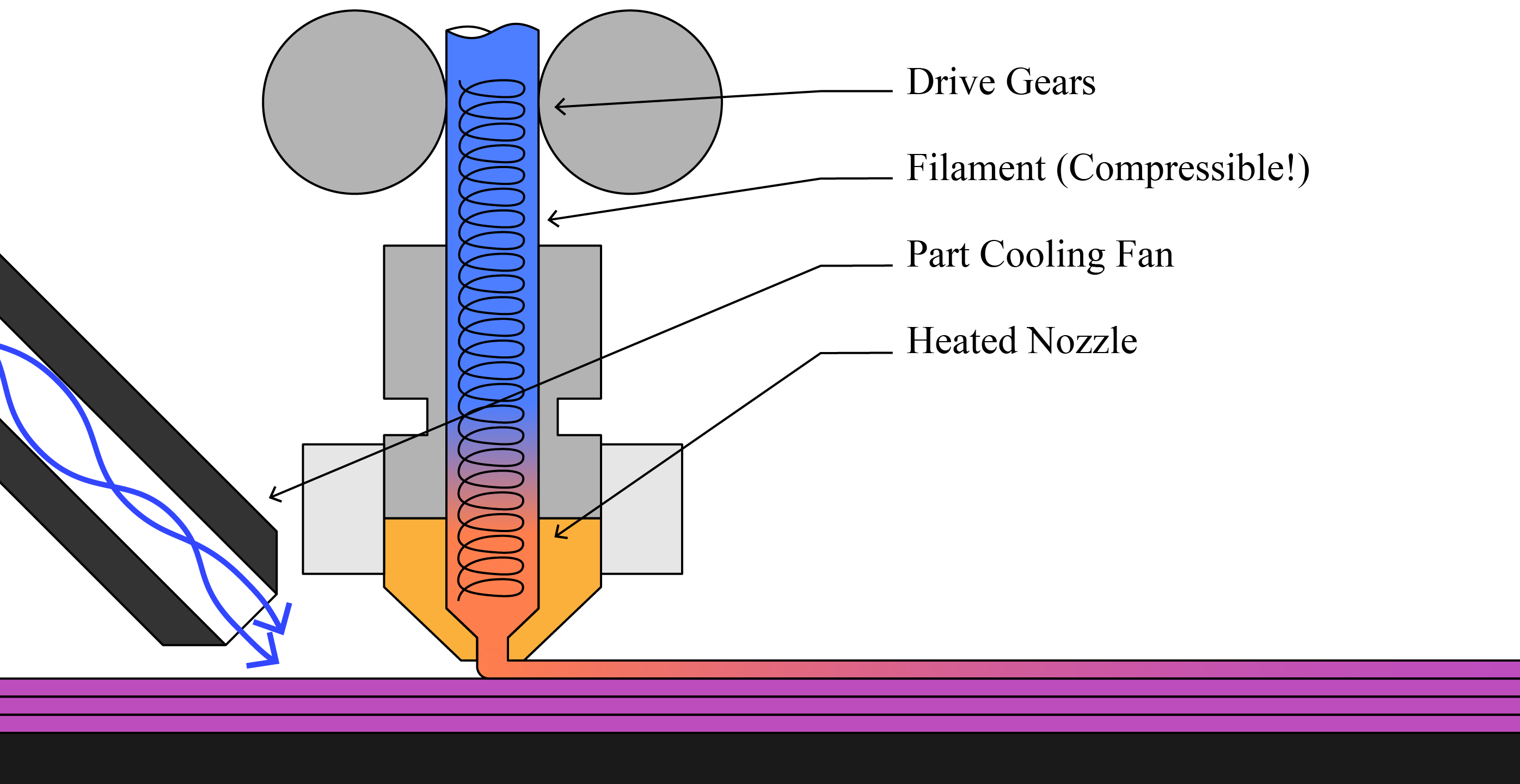

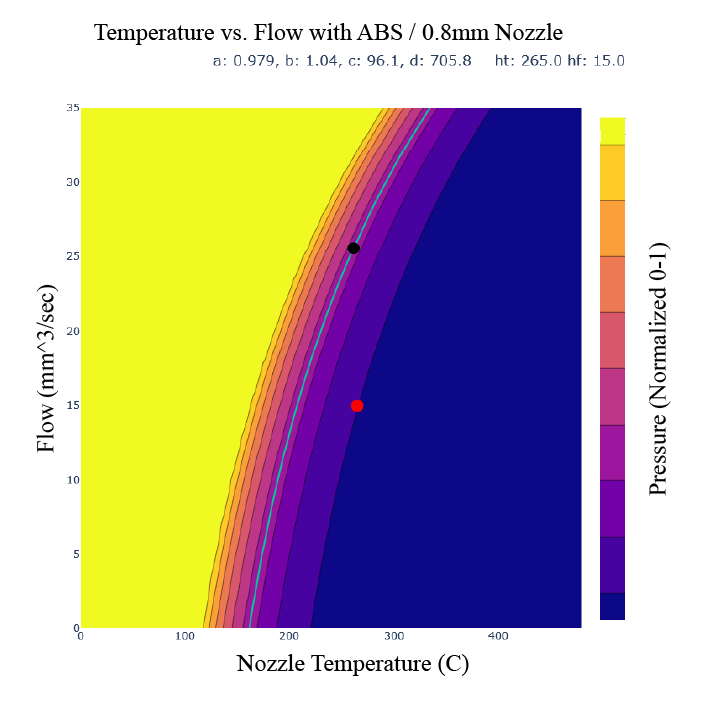

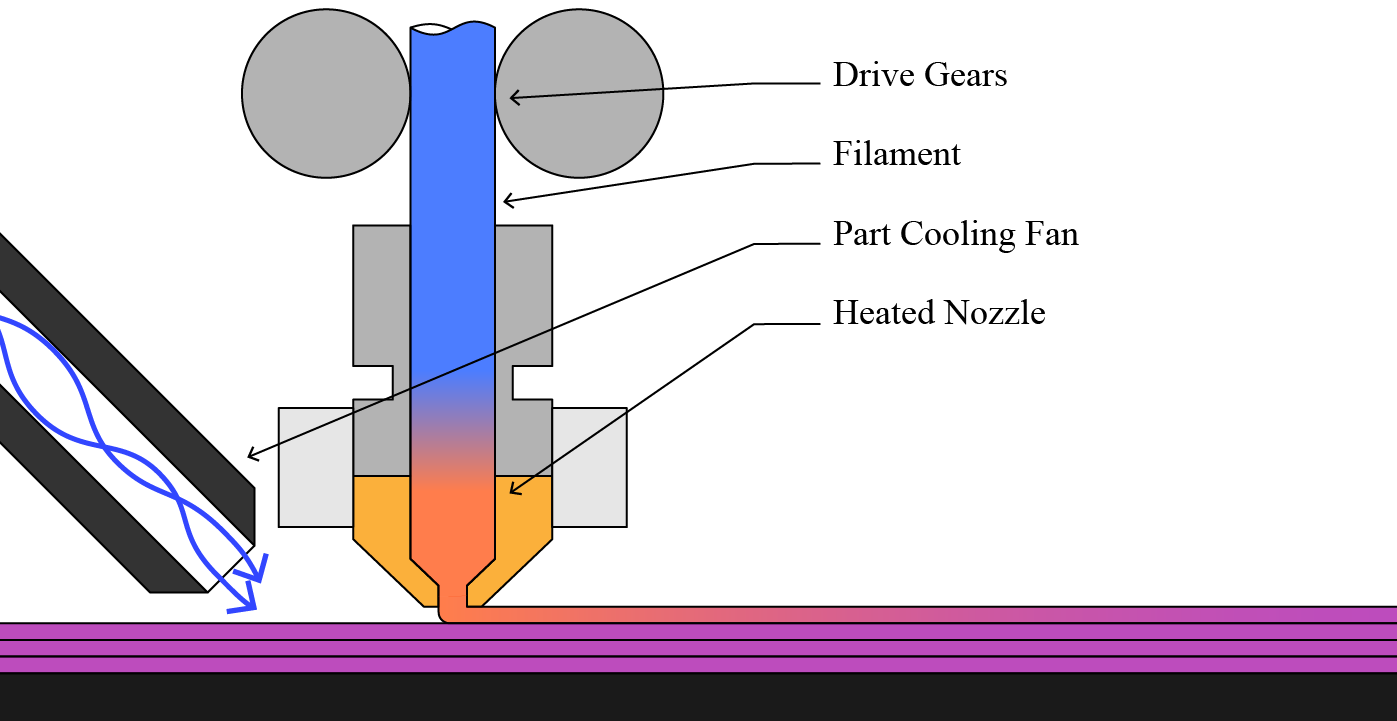

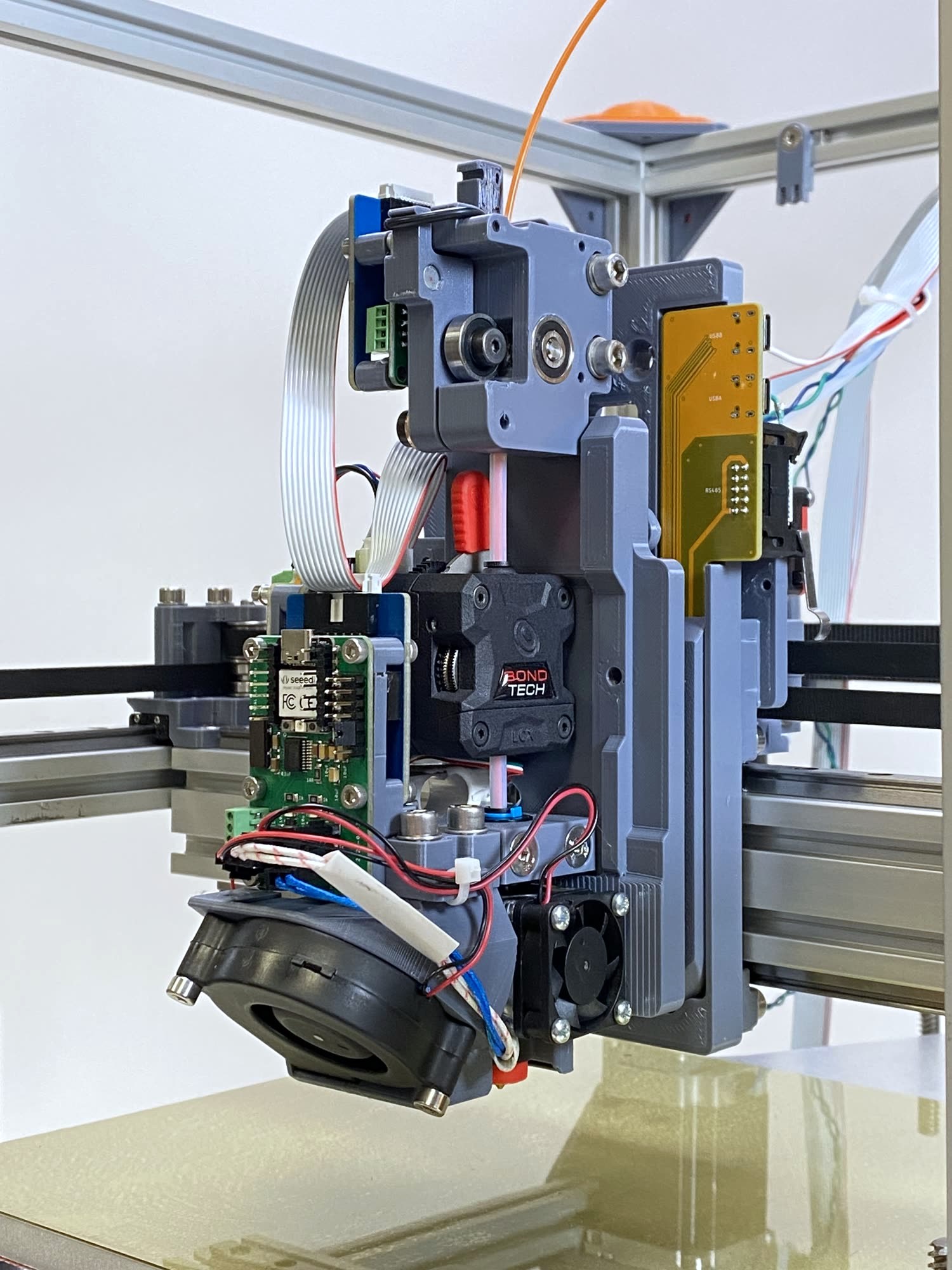

Coogan, Timothy J, and David O Kazmer. 2019. “In-Line Rheological Monitoring of Fused Deposition Modeling.” Journal of Rheology 63 (1): 141-55.

Kazmer, David O., Austin R. Colon, Amy M. Peterson, and Sun Kyoung Kim. 2021. “Concurrent Characterization of Compressibility and Viscosity in Extrusion-Based Additive Manufacturing of Acrylonitrile Butadiene Styrene with Fault Diagnoses.” Additive Manufacturing 46 (October): 102106. https://doi.org/10.1016/j.addma.2021.102106.

Wu, Pinyi. 2024. “Modeling and Feedforward Deposition Control in Fused Filament Fabrication.”

Kazmer, David O., Austin R. Colon, Amy M. Peterson, and Sun Kyoung Kim. 2021. “Concurrent Characterization of Compressibility and Viscosity in Extrusion-Based Additive Manufacturing of Acrylonitrile Butadiene Styrene with Fault Diagnoses.” Additive Manufacturing 46 (October): 102106. https://doi.org/10.1016/j.addma.2021.102106.

Wu, Pinyi. 2024. “Modeling and Feedforward Deposition Control in Fused Filament Fabrication.”

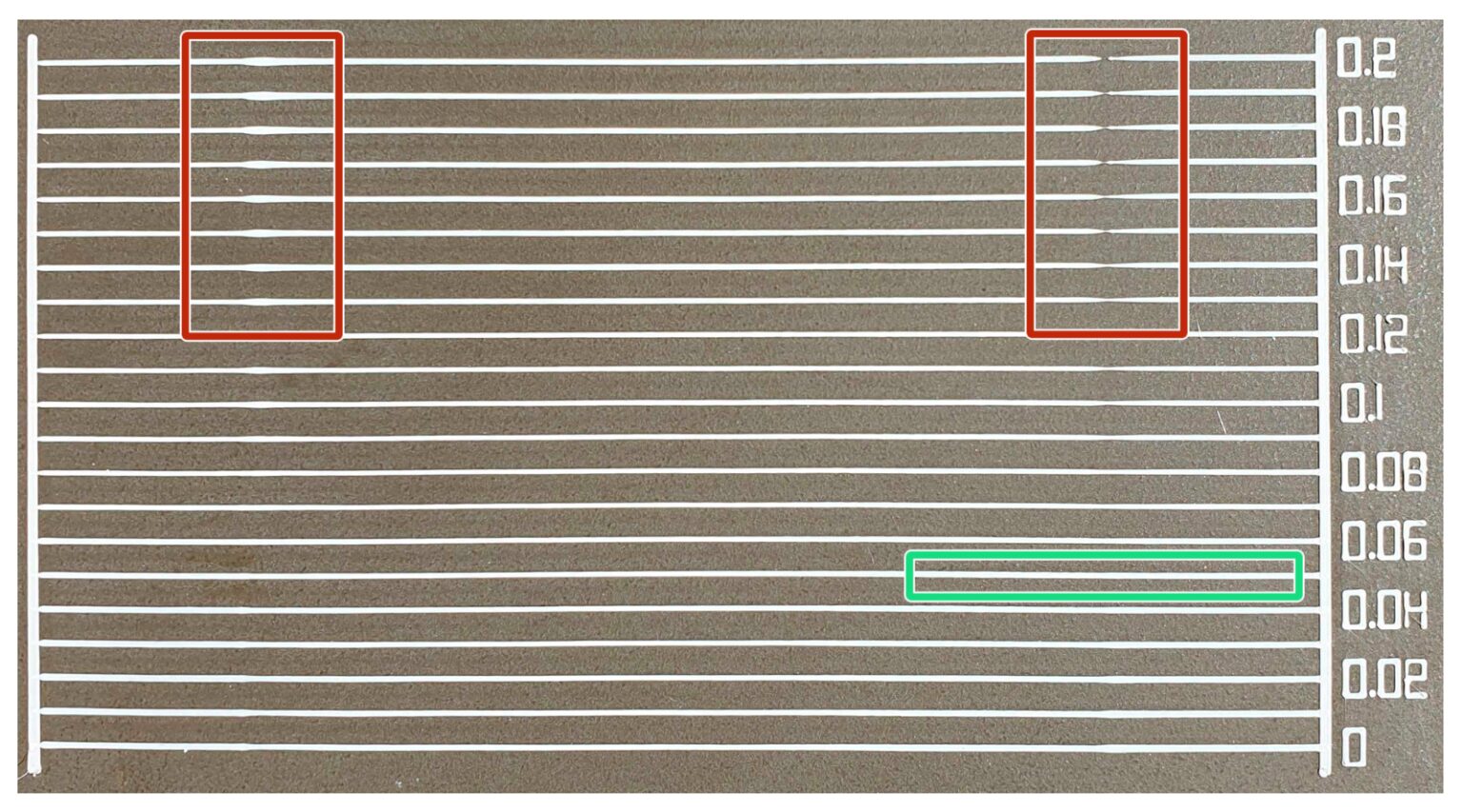

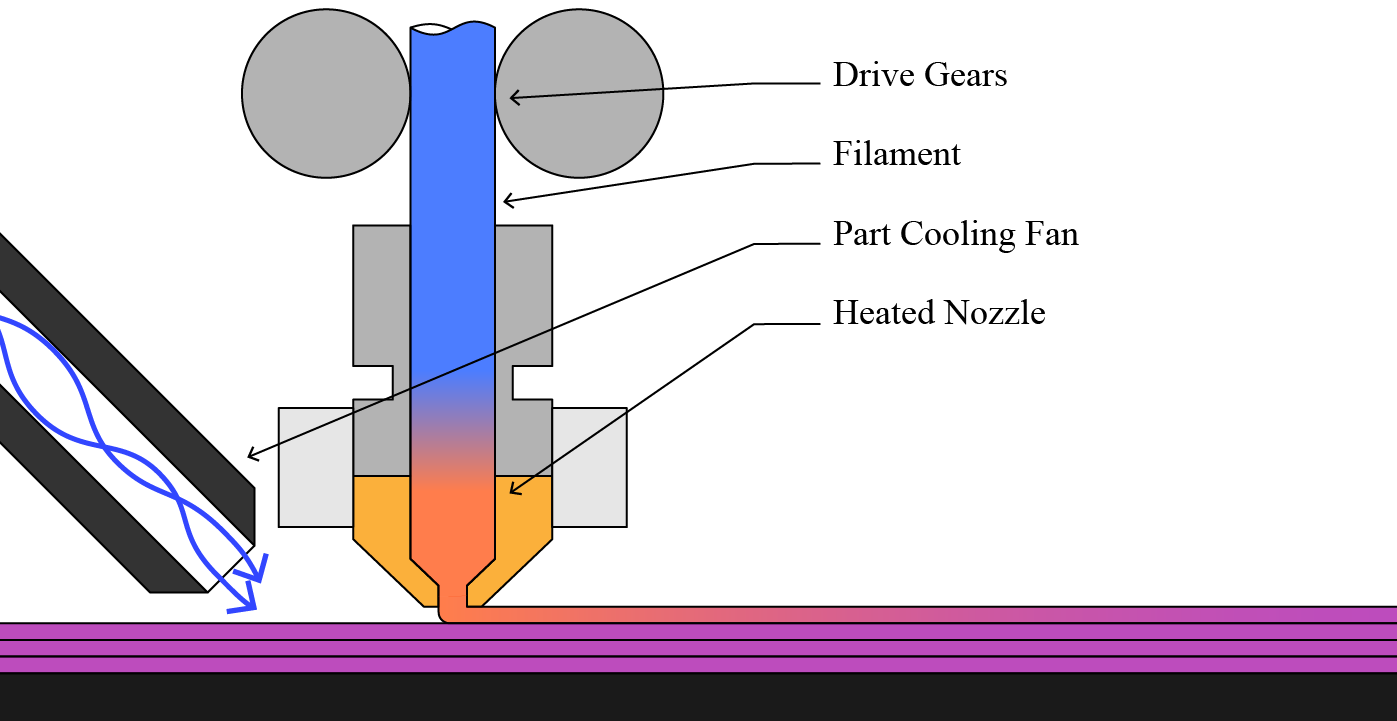

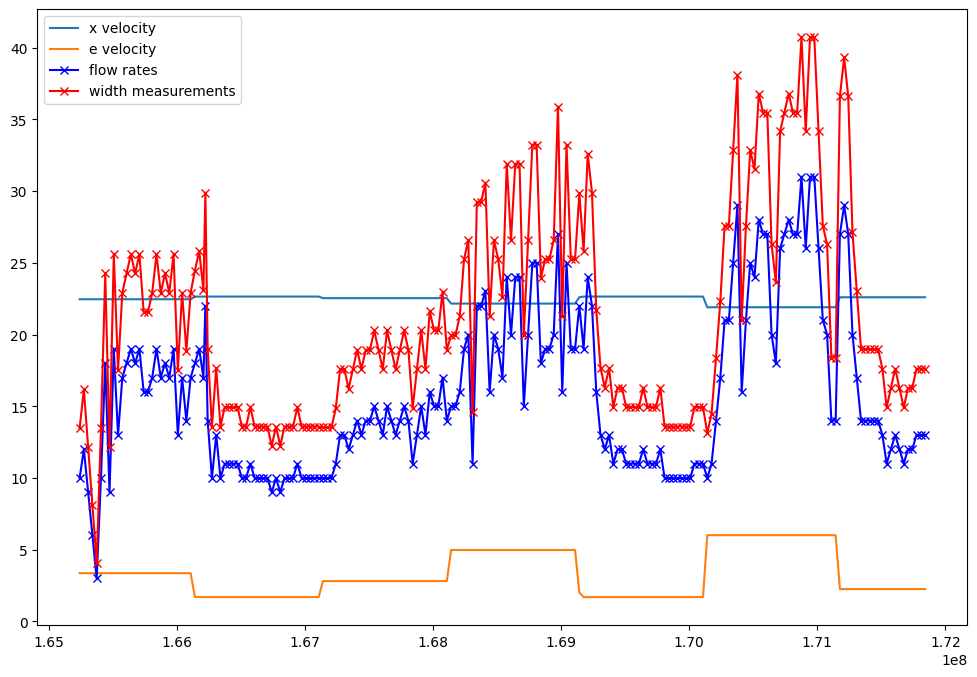

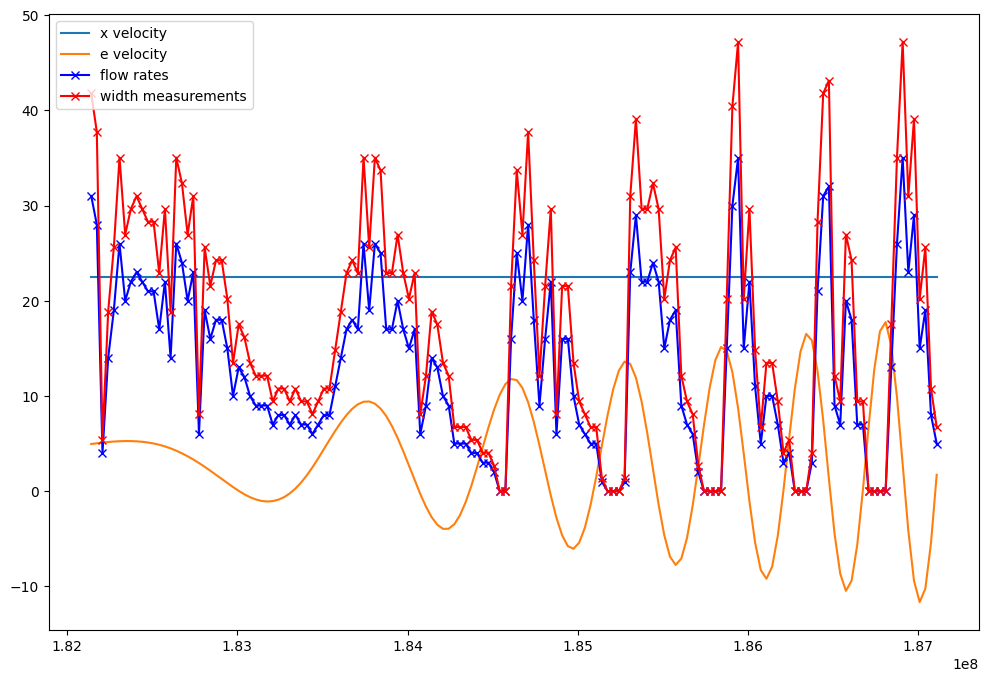

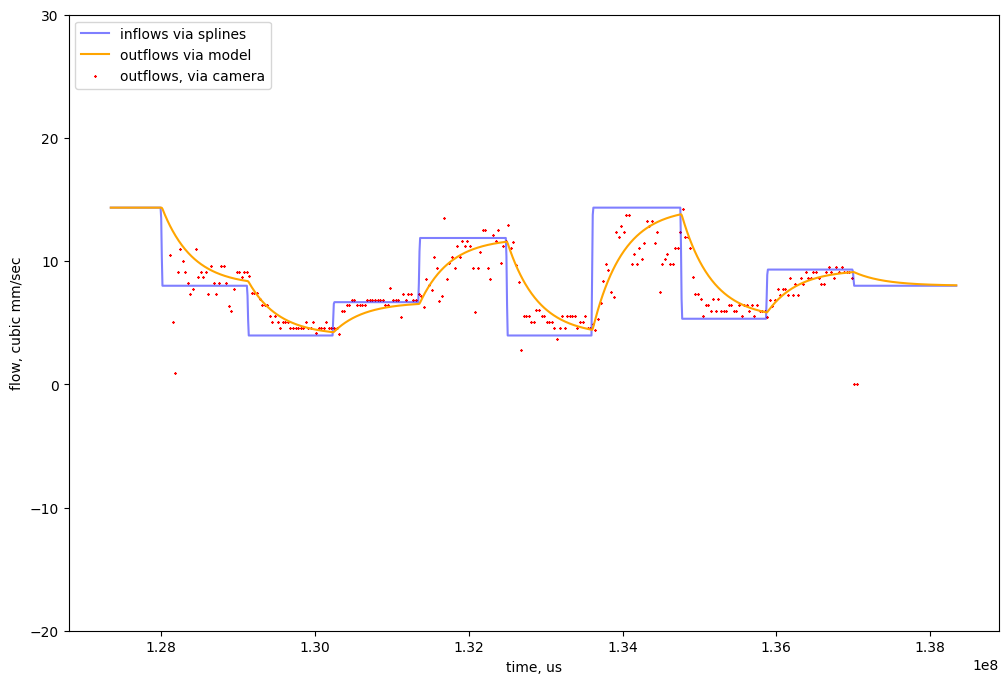

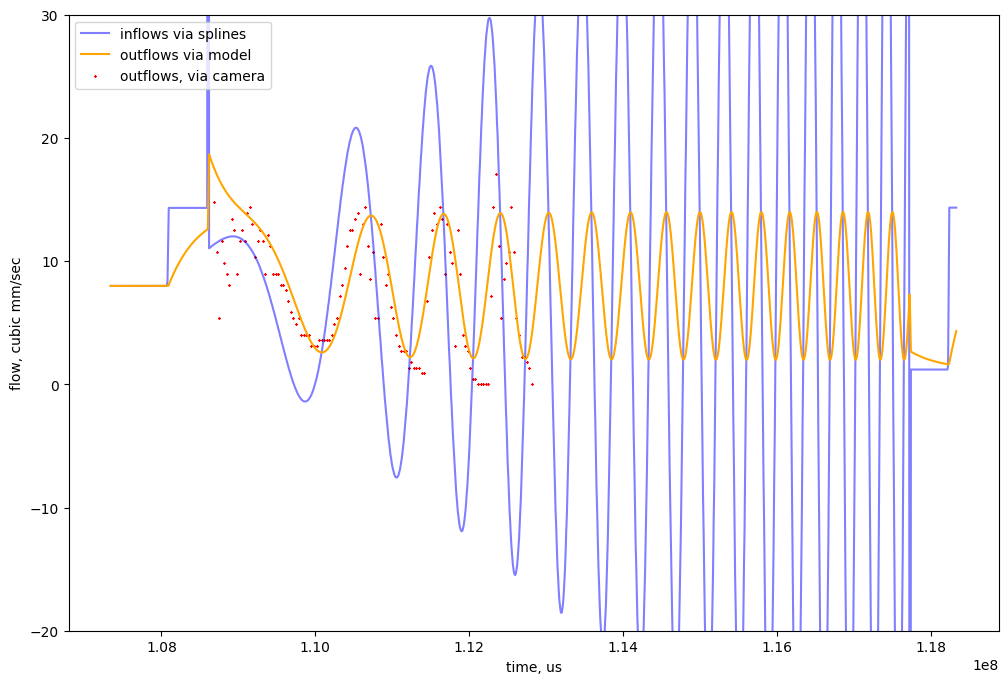

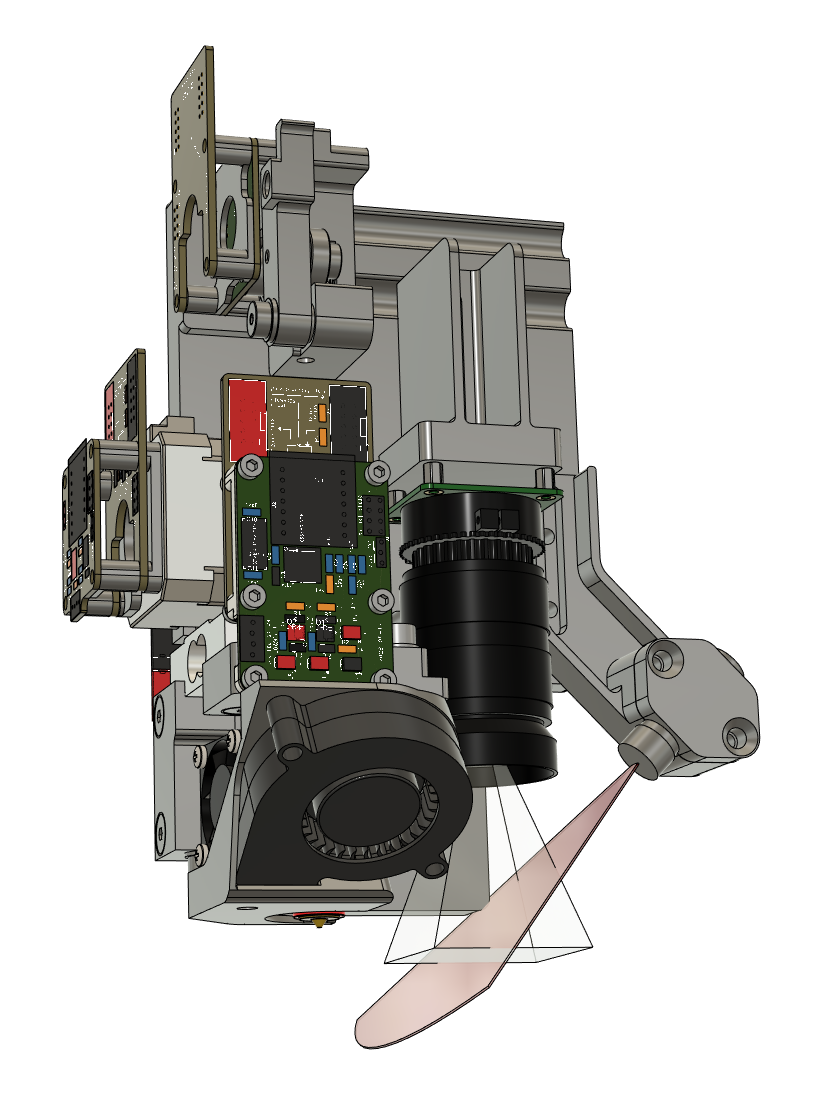

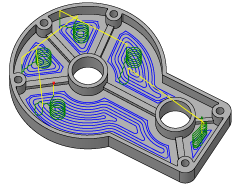

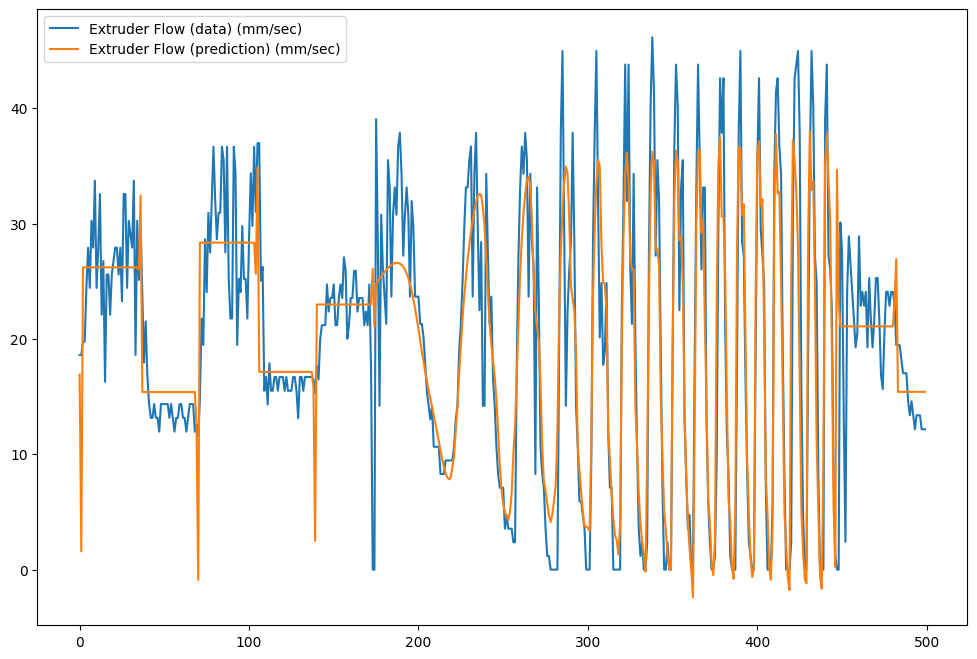

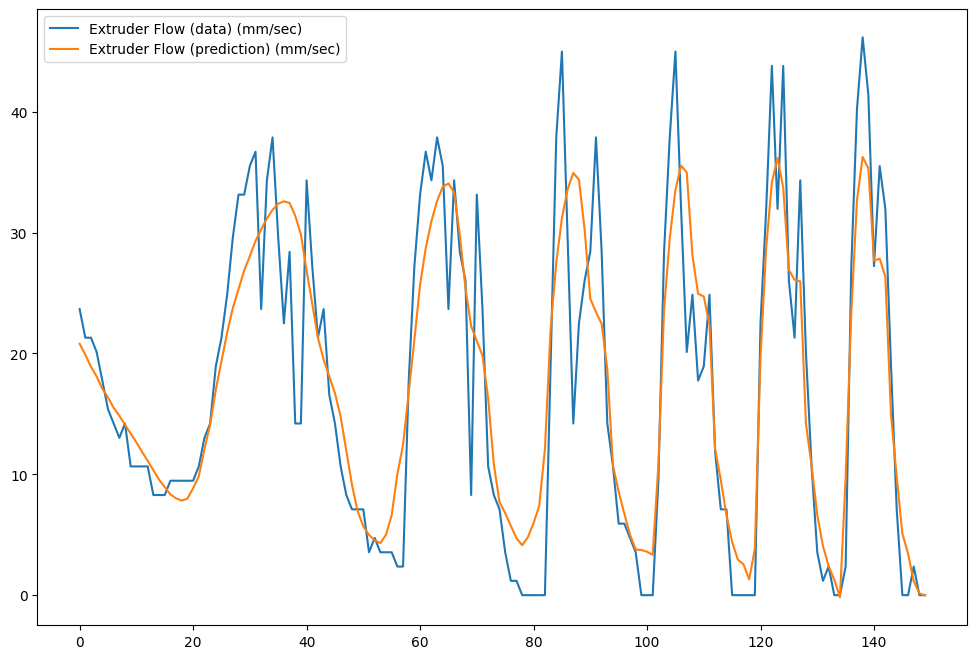

Using track width w/ lateral speed and layer

height to measure flow. W/ Yuval Mamana

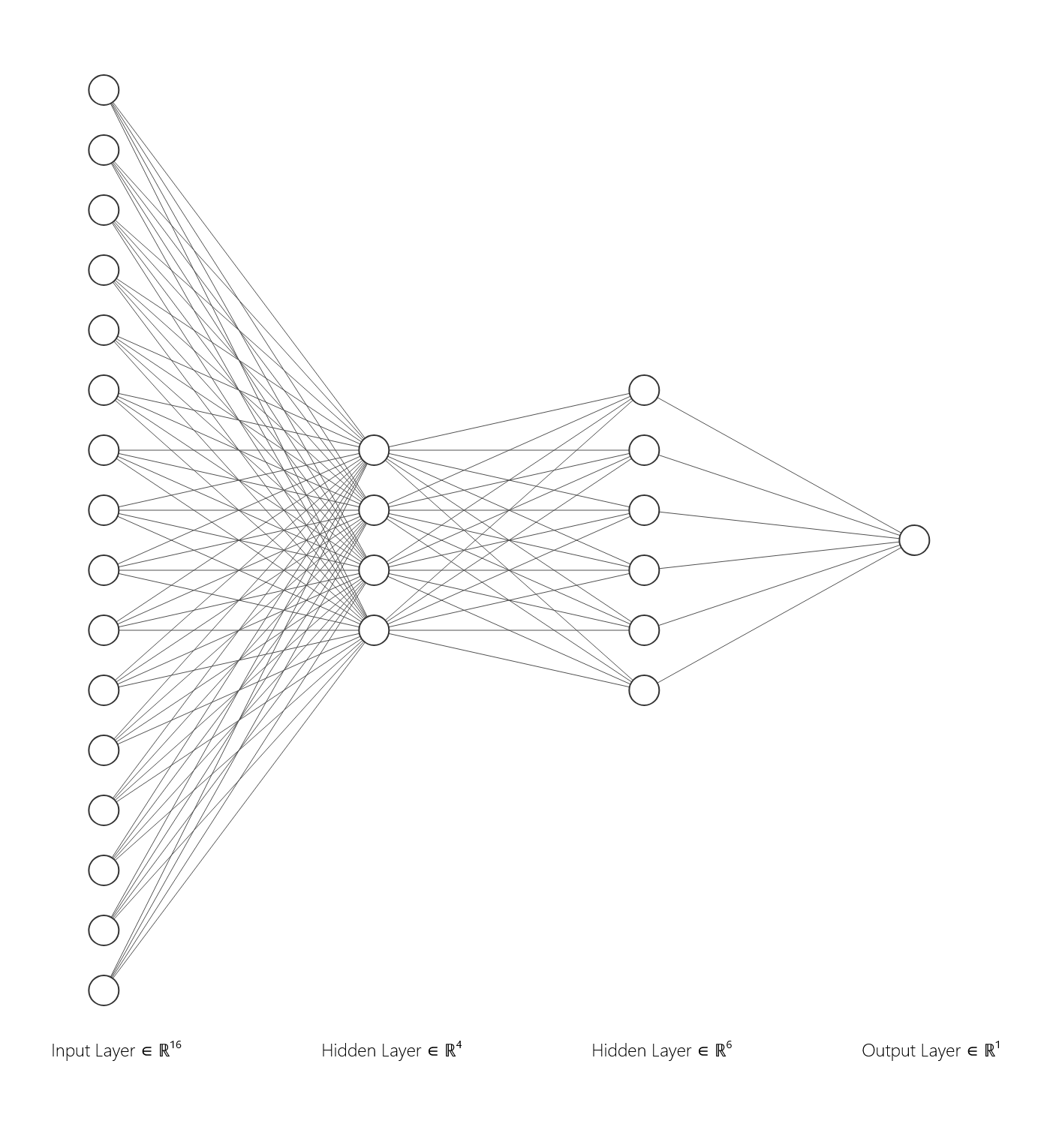

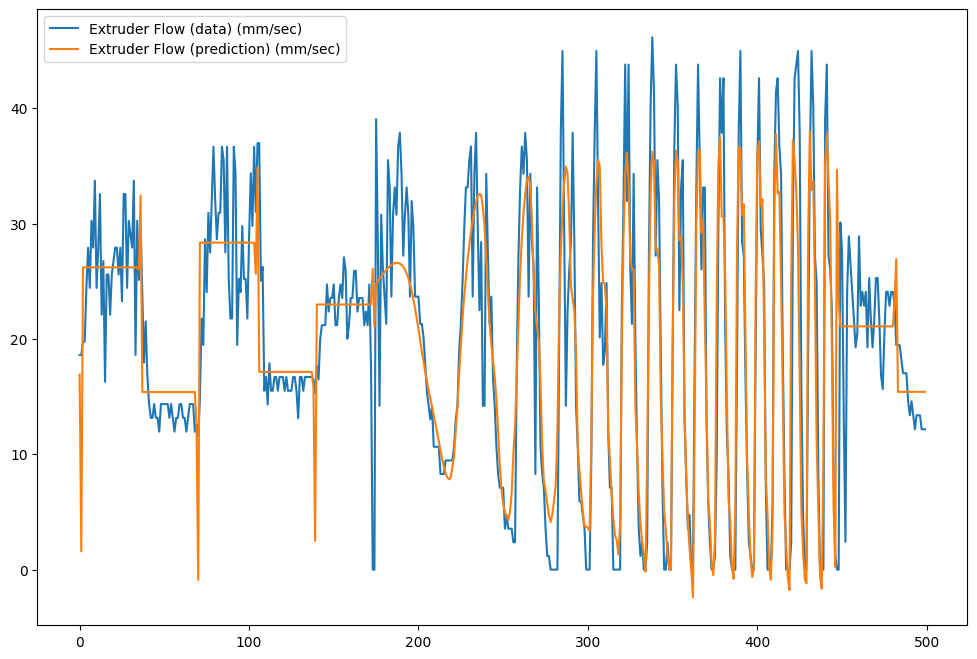

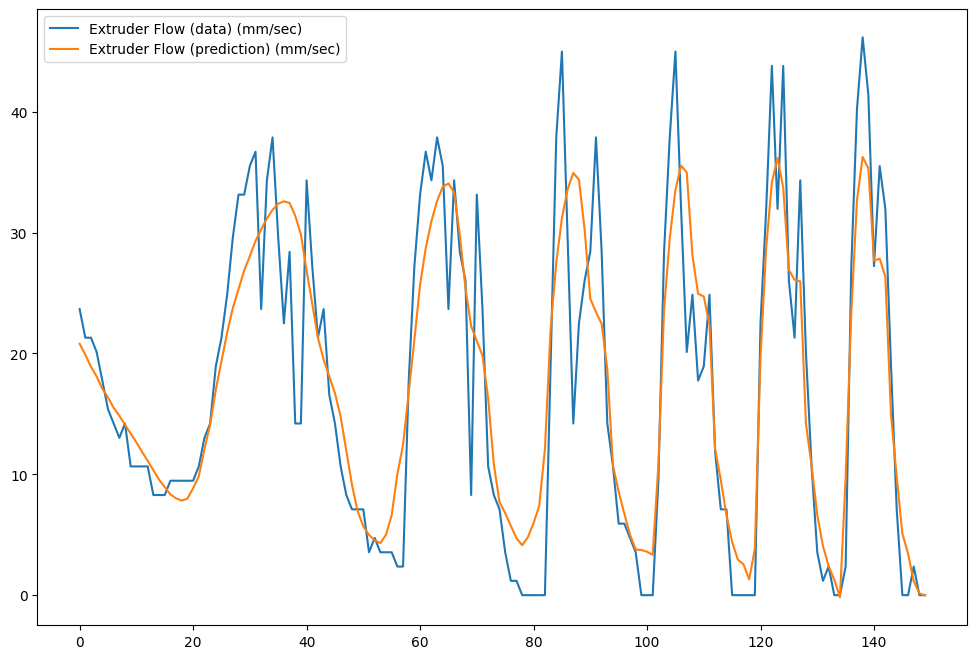

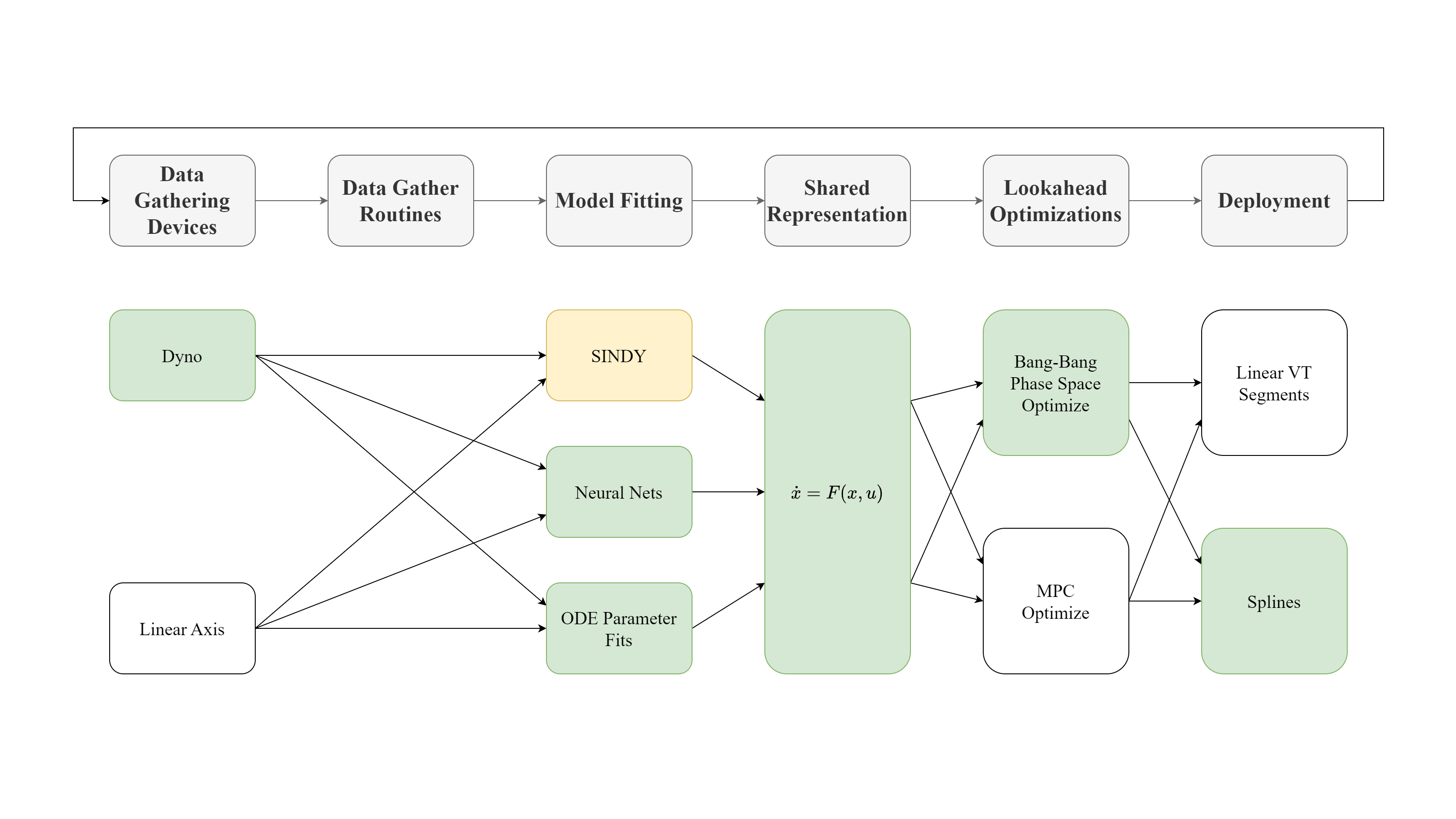

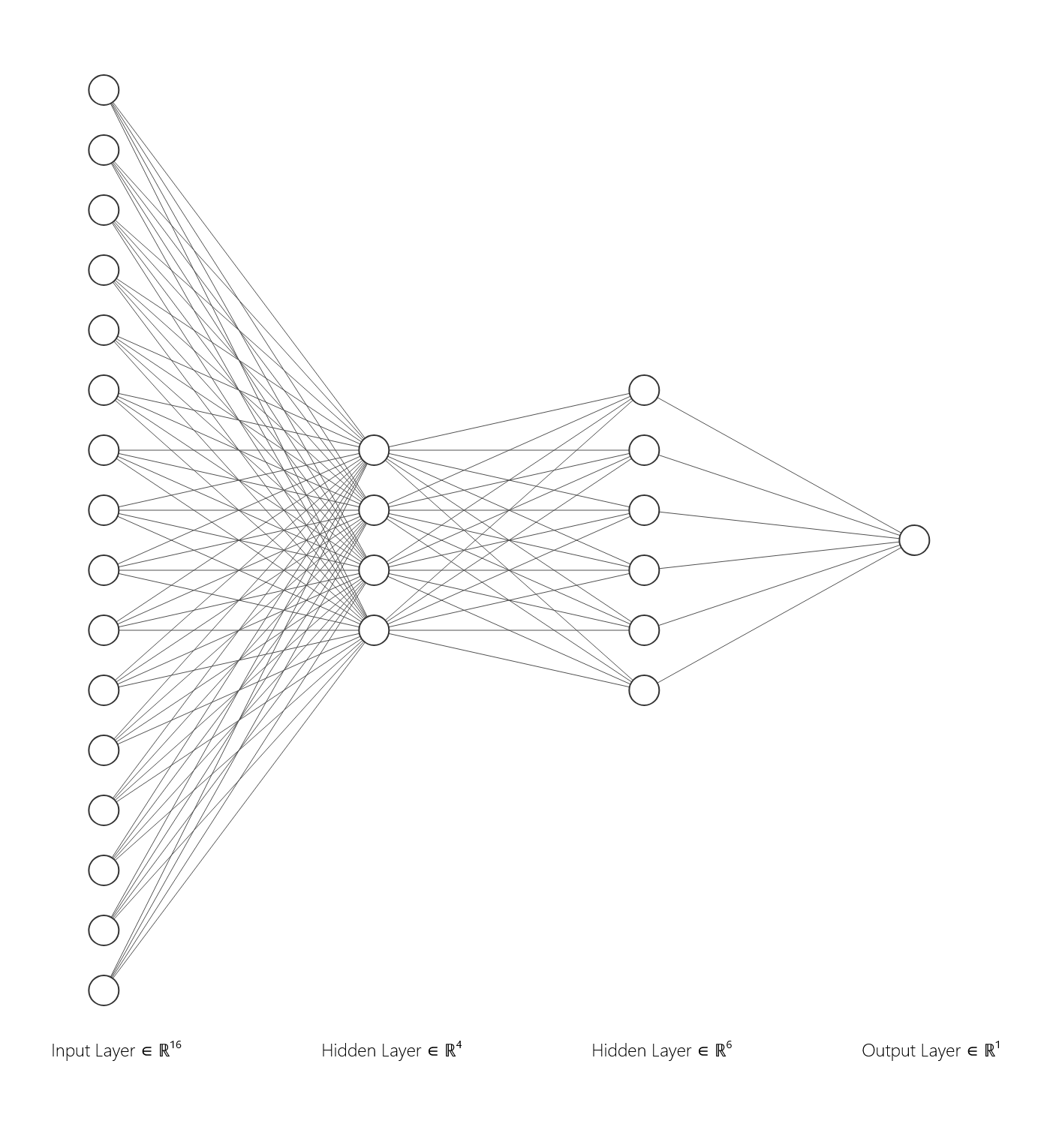

Simple MLP to fit flow, given extruder history.

W/ Yuval Mamana

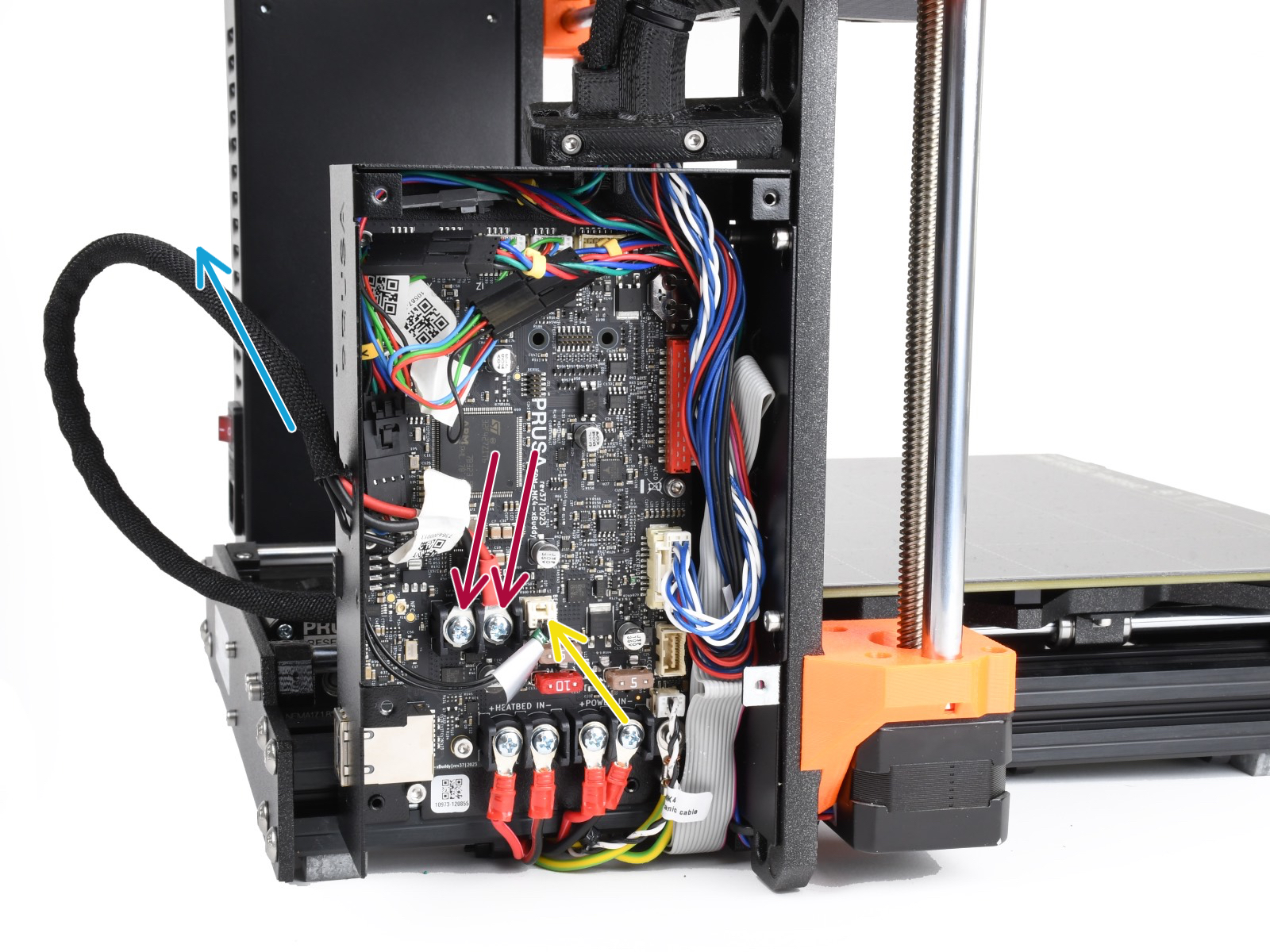

Simple Filament Compression Model

- $\dot{P} = Q_{in} - Q_{out}$

- $Q_{out} = Pk_{outflow}$

- $F_{in} = Tk_{tq} - Pk_{pushback} - Q_{in}k_{fric}$

- $\dot{Q}_{in} = F_{in}$

- Values:

- $Q_{out}$ is outflow (at nozzle)

- $Q_{in}$ is inflow (at motor)

- $P$ is 'pressure' in the chamber: is equivalent here to cubic millimeters of un-extruded filament in the chamber

- $F_{in}, Q_{in}$ are force and velocity for the filament (at the motor)

- Parameters:

- $k_{outflow}$ relates pressure to flow (and could become a function)

- $k_{tq}$ scales torque

- $k_{pushback}$ relates pressure to force (at motor)

- $k_{fric}$ is classic damping friction on the filament

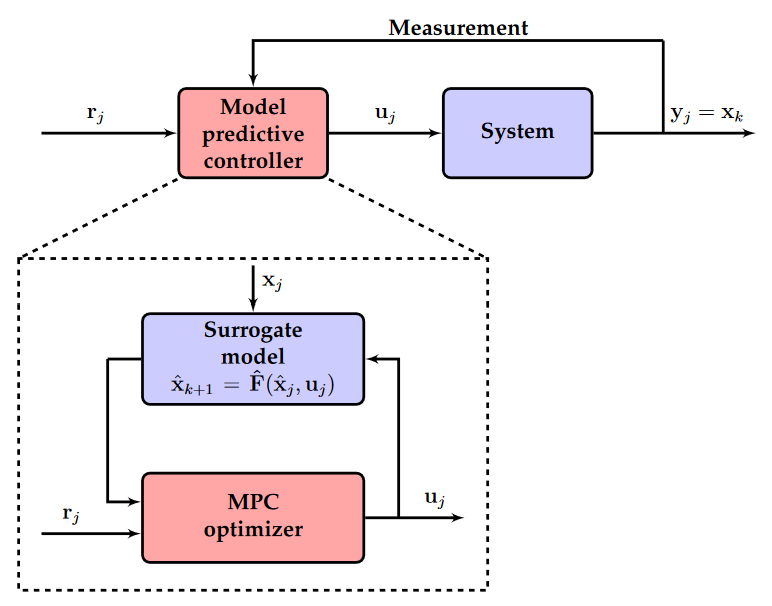

Brunton, Steven L, and J Nathan Kutz. 2022a. “Chapter 10: Data Driven Control.” In Data-Driven

Science and Engineering: Machine Learning, Dynamical Systems, and Control, 389-408. Cambridge,

United Kingdom: Cambridge University Press.

Di Carlo, Jared, Patrick M Wensing, Benjamin Katz, Gerardo Bledt, and Sangbae Kim. 2018. “Dynamic Locomotion in the Mit Cheetah 3 Through Convex Model-Predictive Control.” In 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), 1-9. IEEE.

Torrente, Guillem, Elia Kaufmann, Philipp Föhn, and Davide Scaramuzza. 2021. “Data-Driven MPC for Quadrotors.” IEEE Robotics and Automation Letters 6 (2): 3769-76.

Kuindersma, Scott, Robin Deits, Maurice Fallon, Andrés Valenzuela, Hongkai Dai, Frank Permenter, Twan Koolen, Pat Marion, and Russ Tedrake. 2016. “Optimization-Based Locomotion Planning, Estimation, and Control Design for the Atlas Humanoid Robot.” Autonomous Robots 40: 429-55.

Torrente, Guillem, Elia Kaufmann, Philipp Föhn, and Davide Scaramuzza. 2021. “Data-Driven MPC for Quadrotors.” IEEE Robotics and Automation Letters 6 (2): 3769-76.

Kuindersma, Scott, Robin Deits, Maurice Fallon, Andrés Valenzuela, Hongkai Dai, Frank Permenter, Twan Koolen, Pat Marion, and Russ Tedrake. 2016. “Optimization-Based Locomotion Planning, Estimation, and Control Design for the Atlas Humanoid Robot.” Autonomous Robots 40: 429-55.

Definition of Forward Model for Motion

def integrate_pos(torques, vel, pos, del_t):

params_torques = jnp.array([2000, 1000]) # motor juice per-axis

params_frictional = jnp.array([2, 2]) # damping

torques = jnp.clip(torques, -1, 1)

torques = torques * params_torques

acc = torques - params_frictional * vel

vel = vel + acc * del_t

pos = pos + vel * del_t

return acc, vel, pos

Definition of Forward Model for Polymer Flow

def integrate_flow(torque, inflow, pres, del_t):

k_outflow = 2.85 # outflow = pres*k_outflow

k_tq = 1 # torque scalar,

k_pushback = 10 # relates pressure to torque

k_fric = 0.2 # damping

torque = np.clip(torque, -1, 1)

# calculate force at top (inflow) and integrate for new inflow

force_in = torque * k_tq - inflow * k_fric - np.clip(pres, 0, np.inf) * k_pushback

inflow = inflow + force_in * del_t

# outflow... related to previous pressure, is just proportional

outflow = pres * k_outflow

# pressure... rises w/ each tick of inflow, drops w/ outflow,

pres = pres + inflow * del_t - outflow * del_t

# that's all for now?

return outflow, inflow, pres

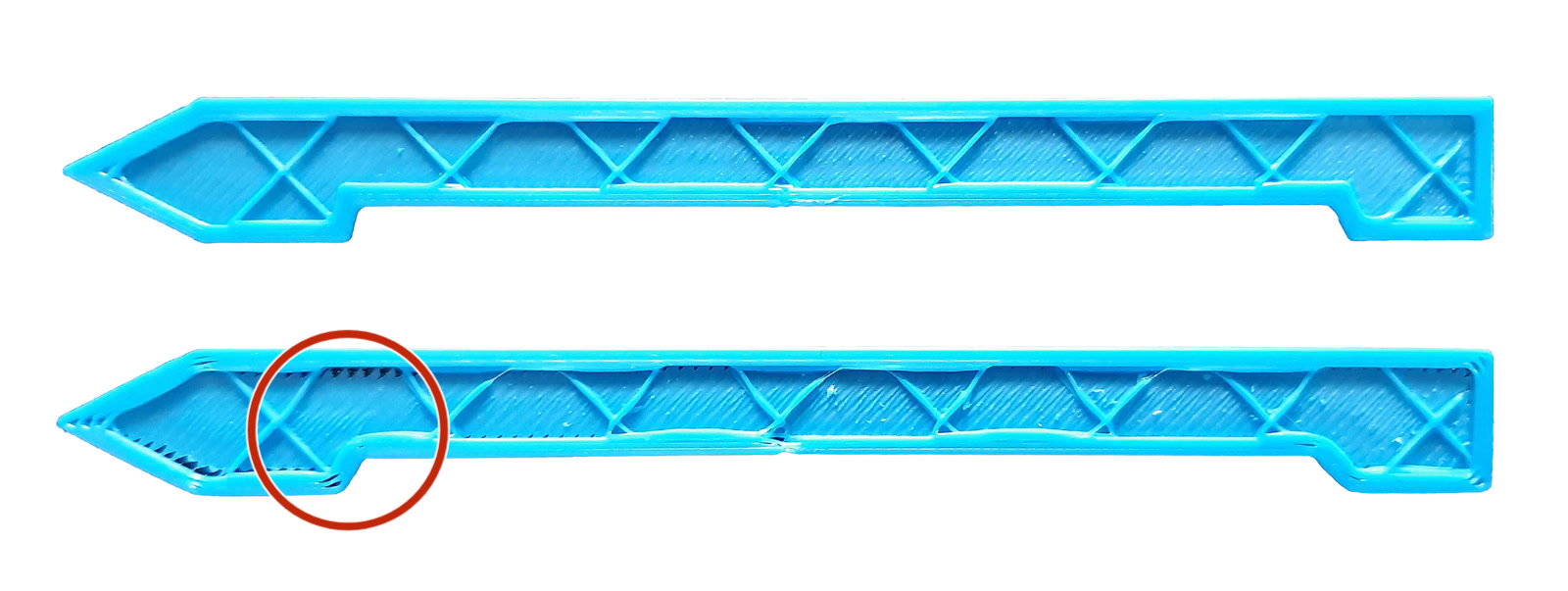

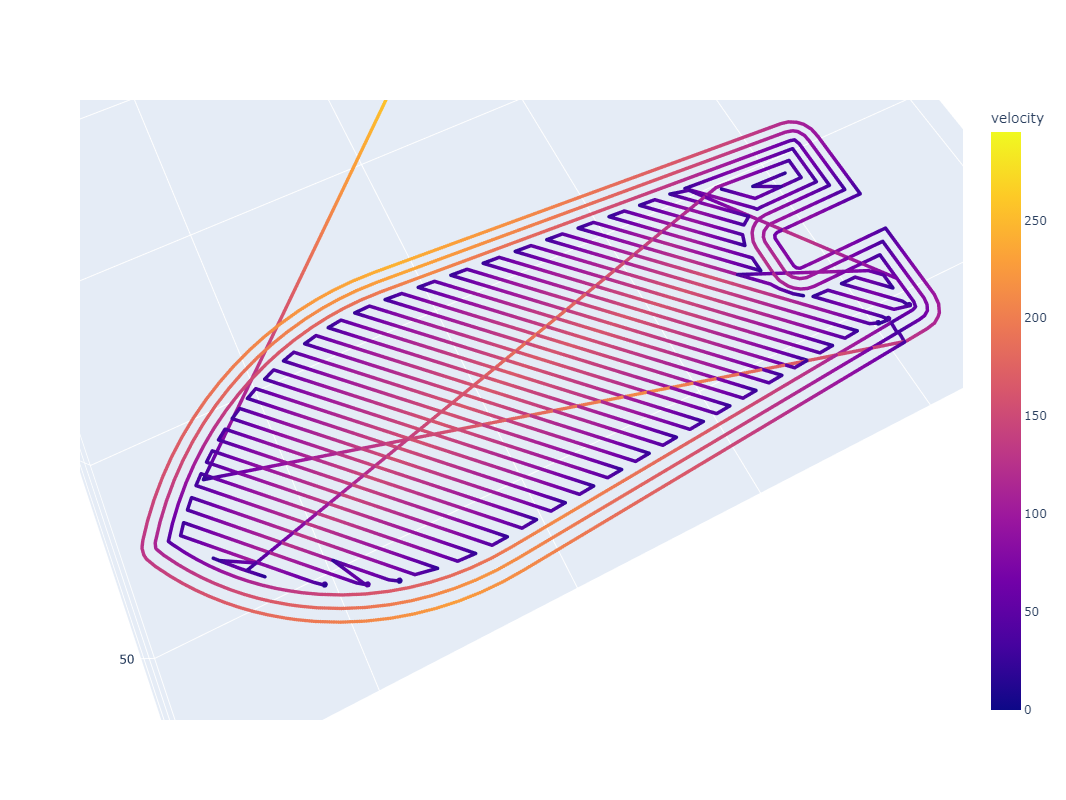

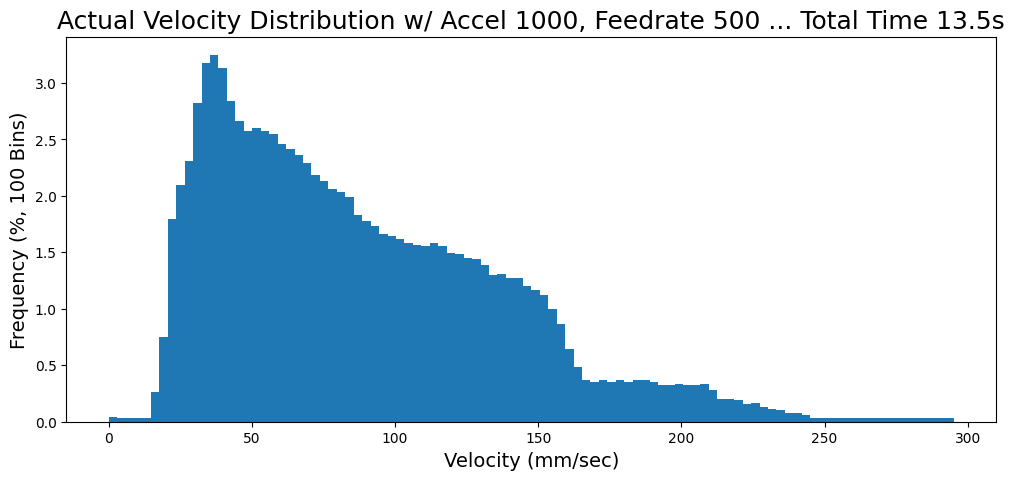

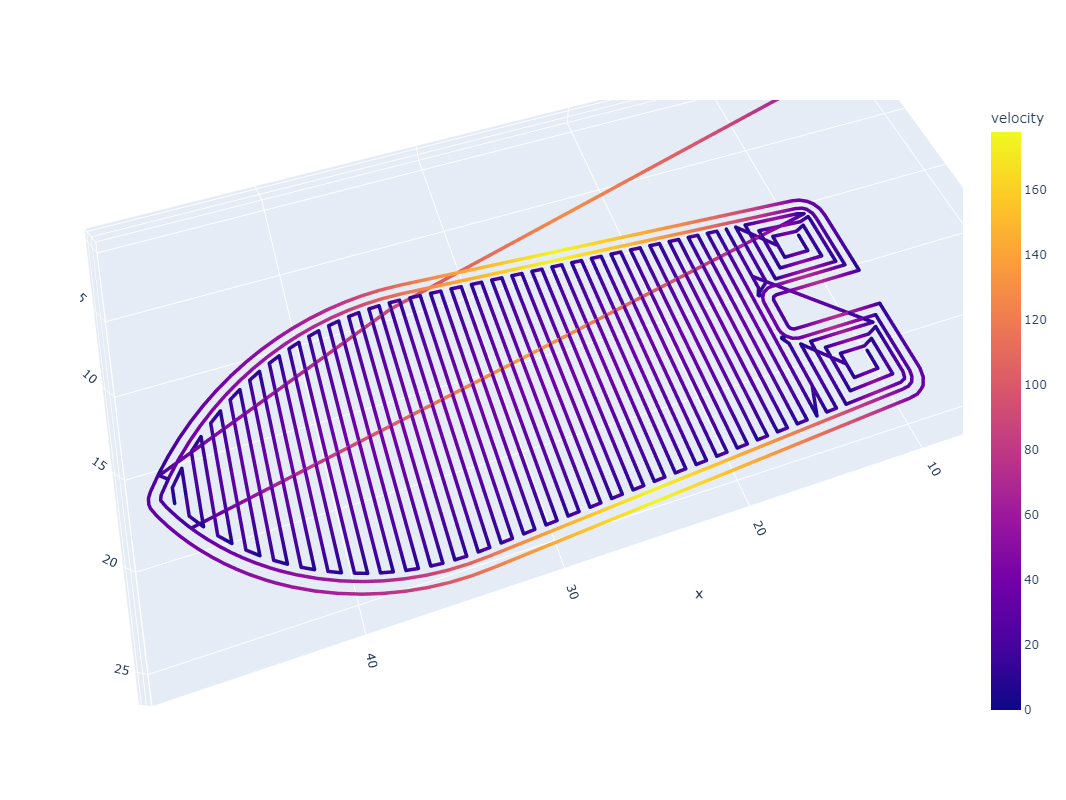

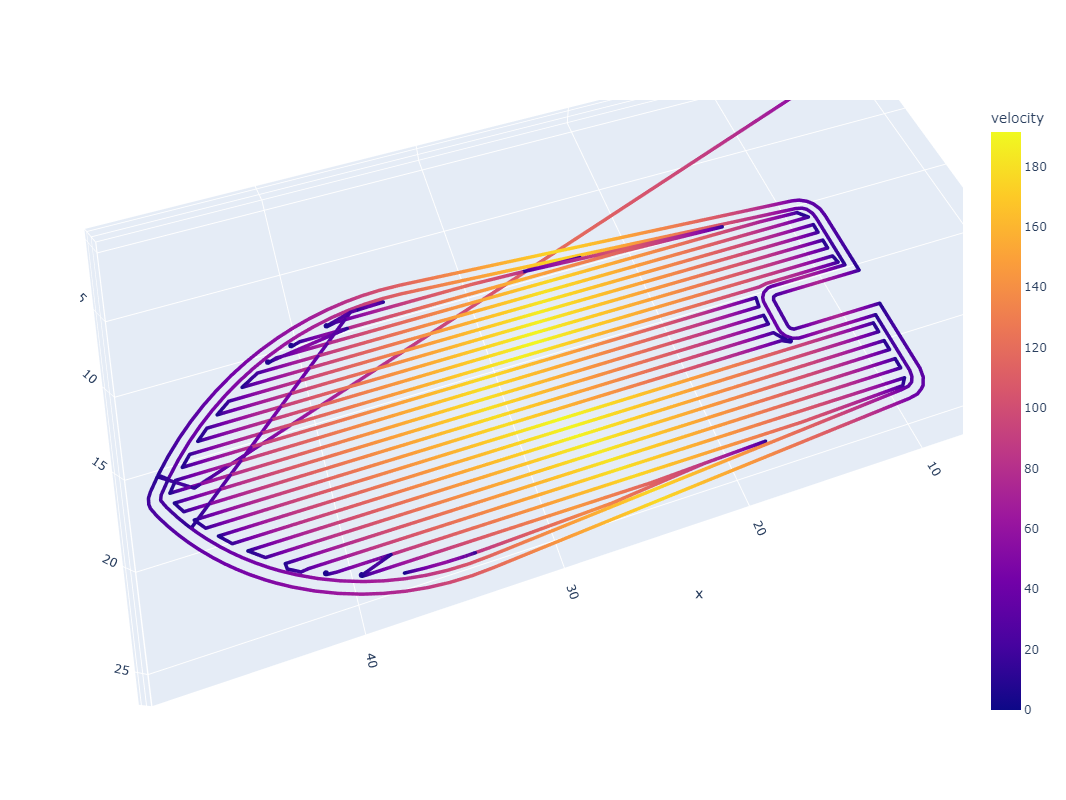

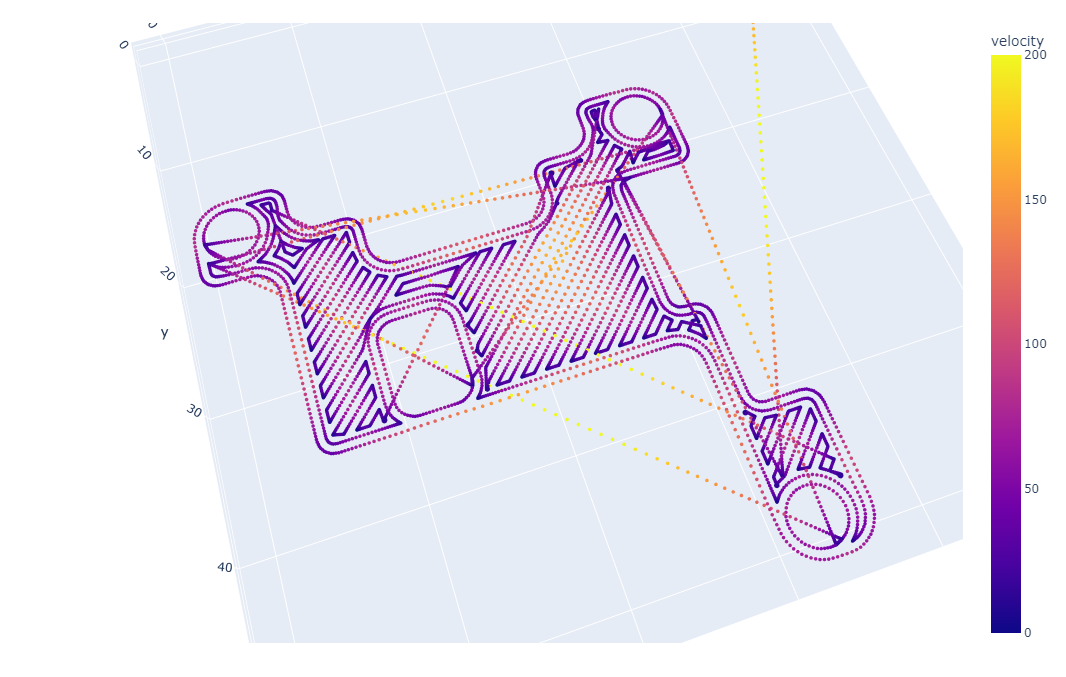

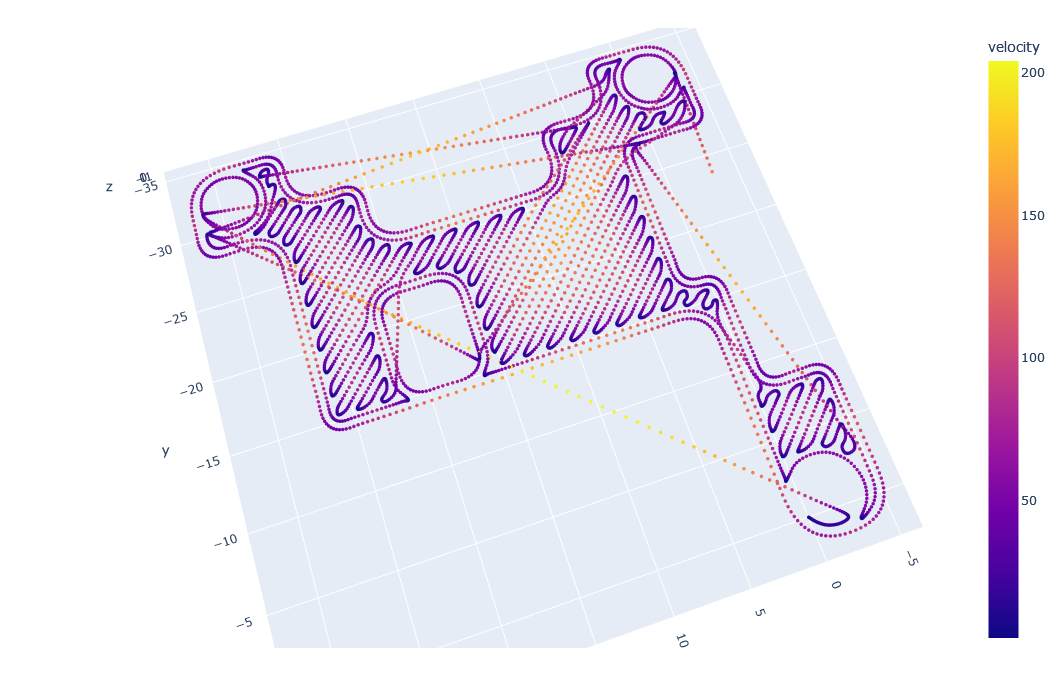

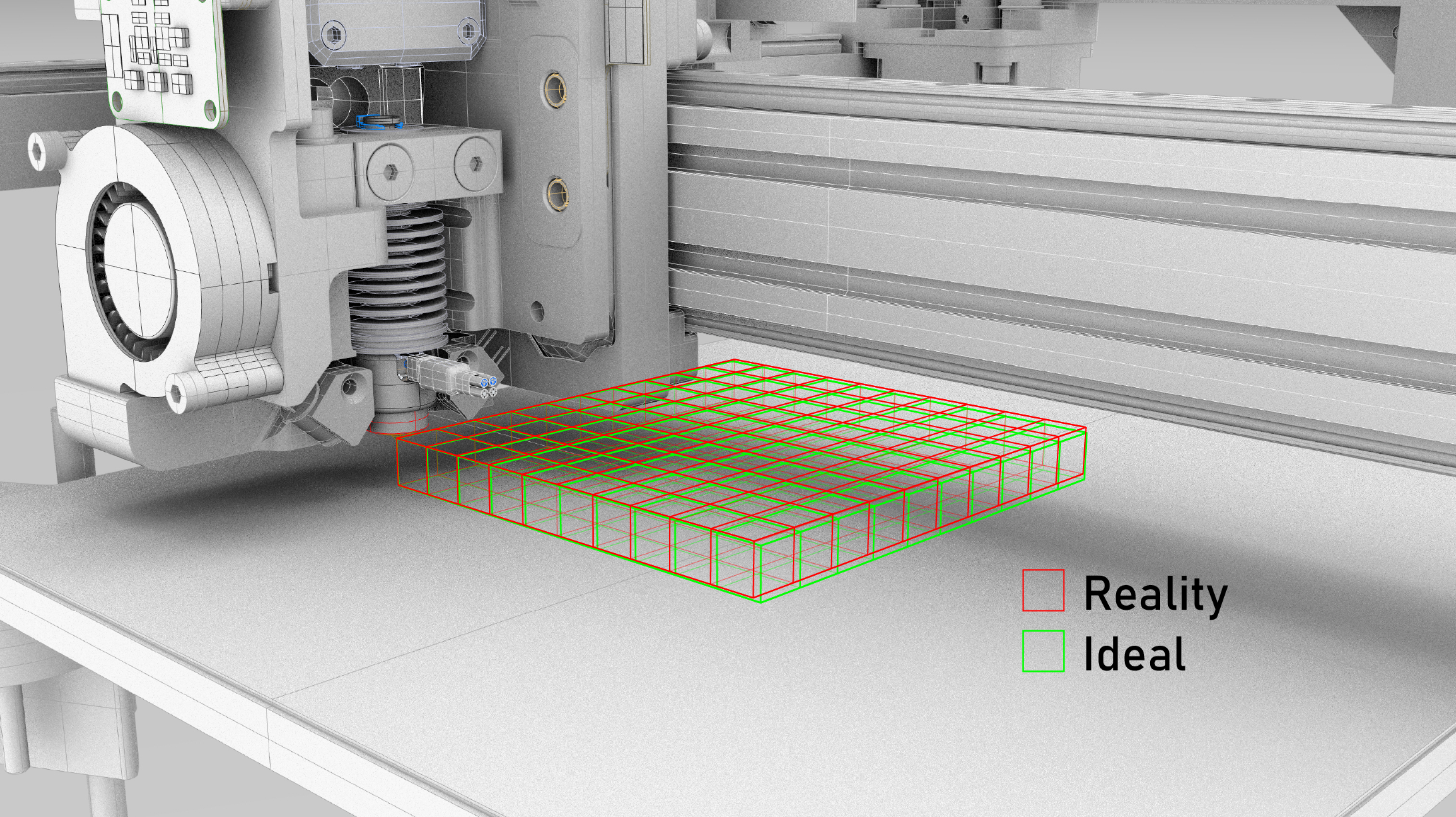

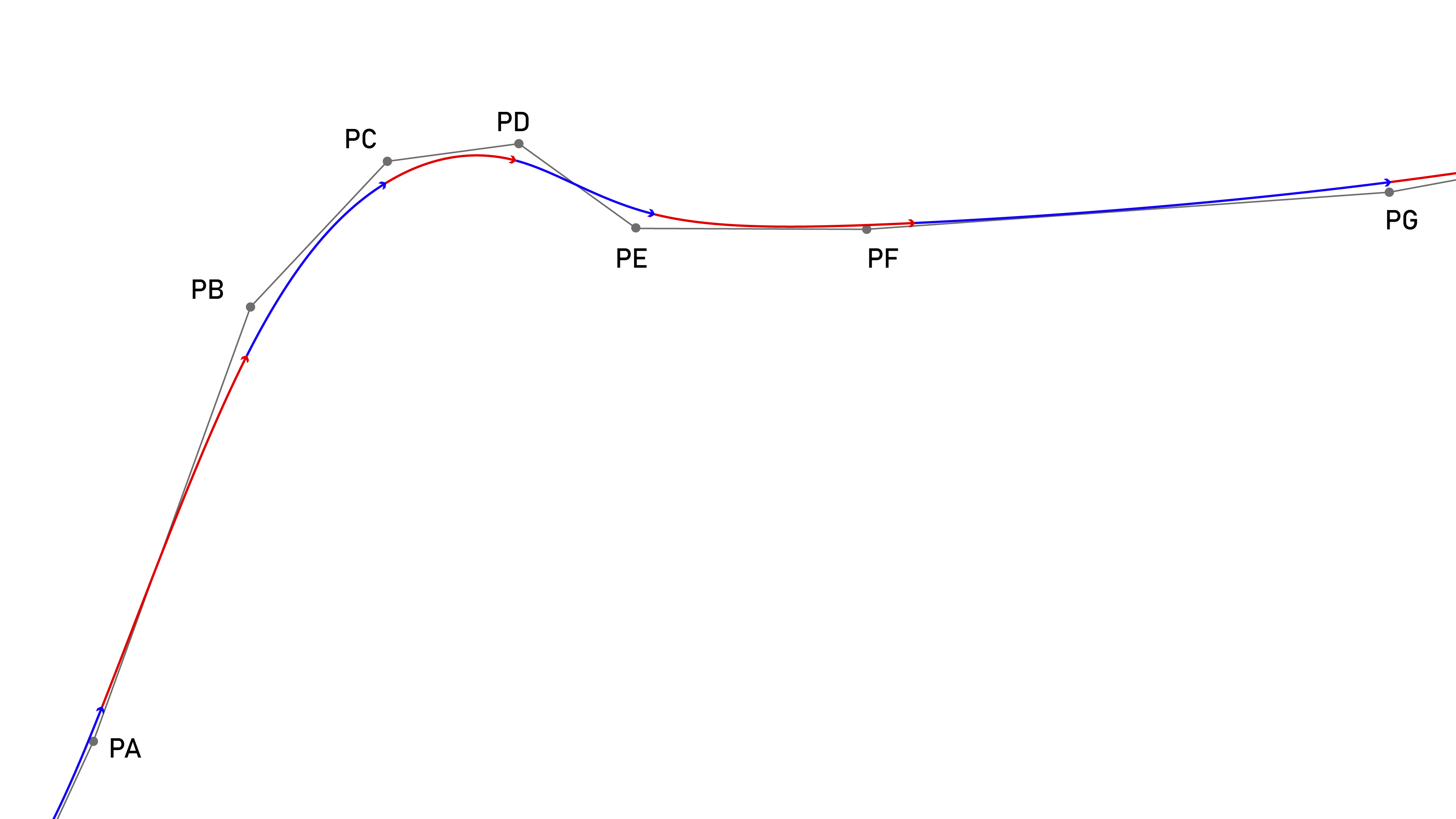

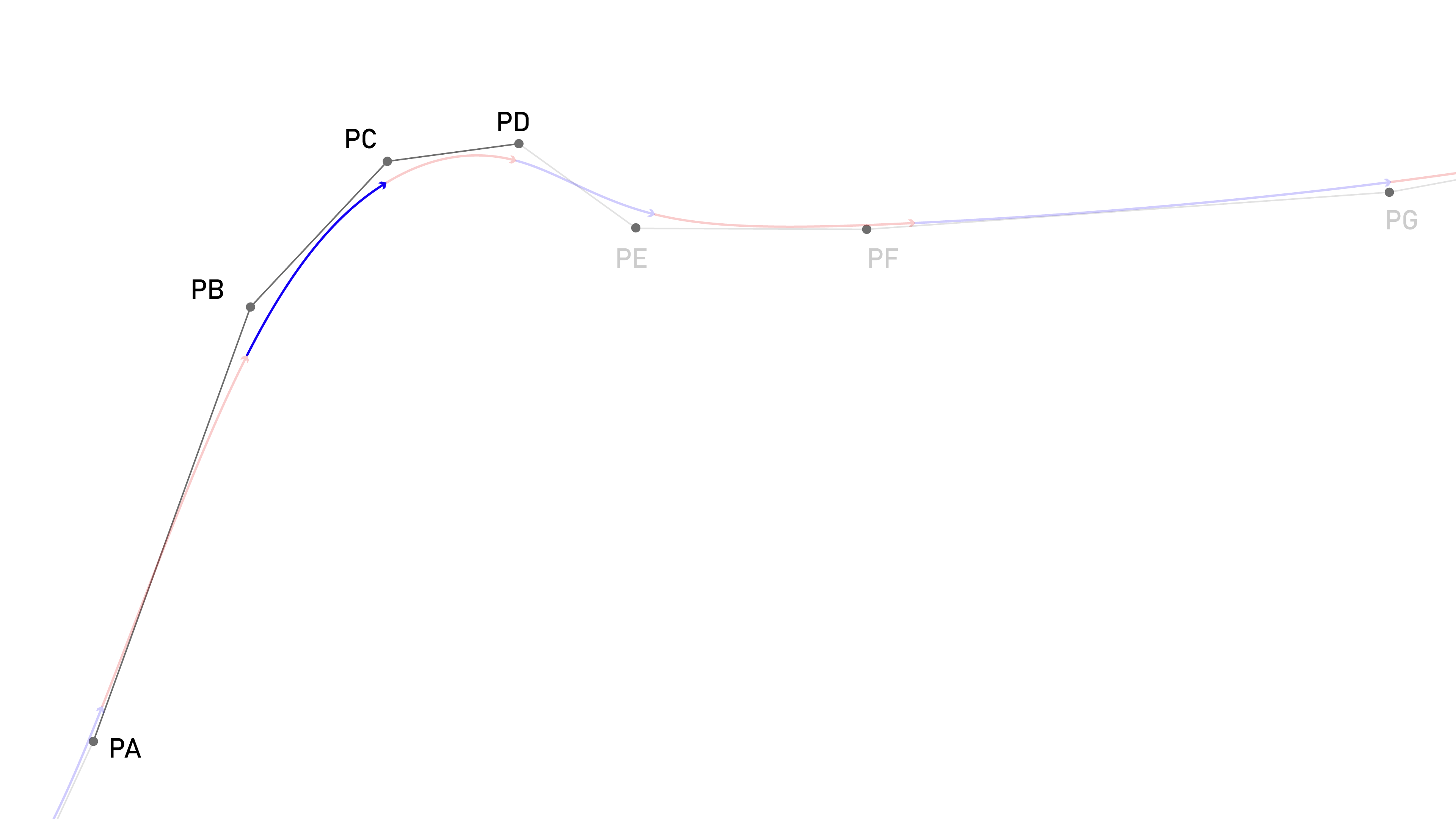

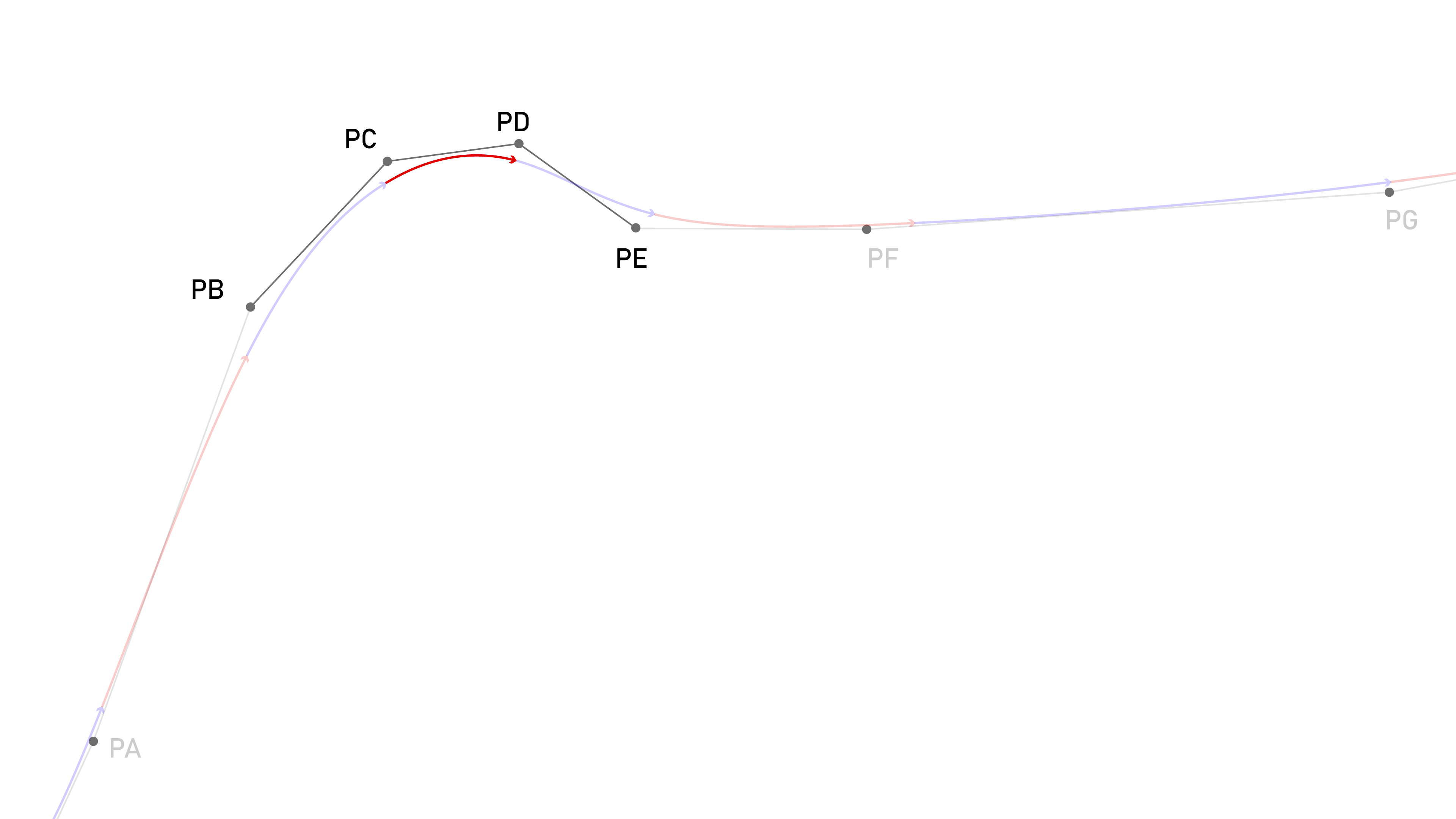

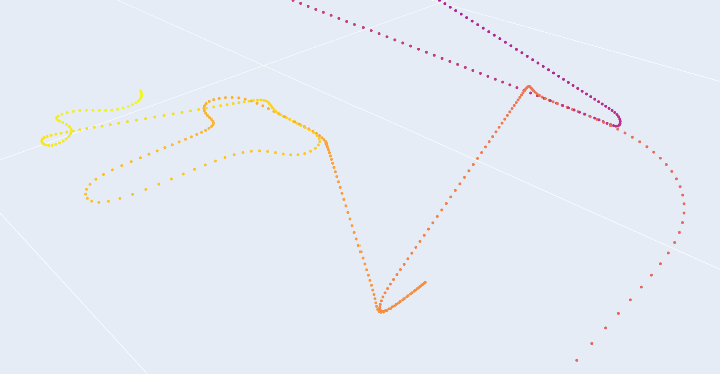

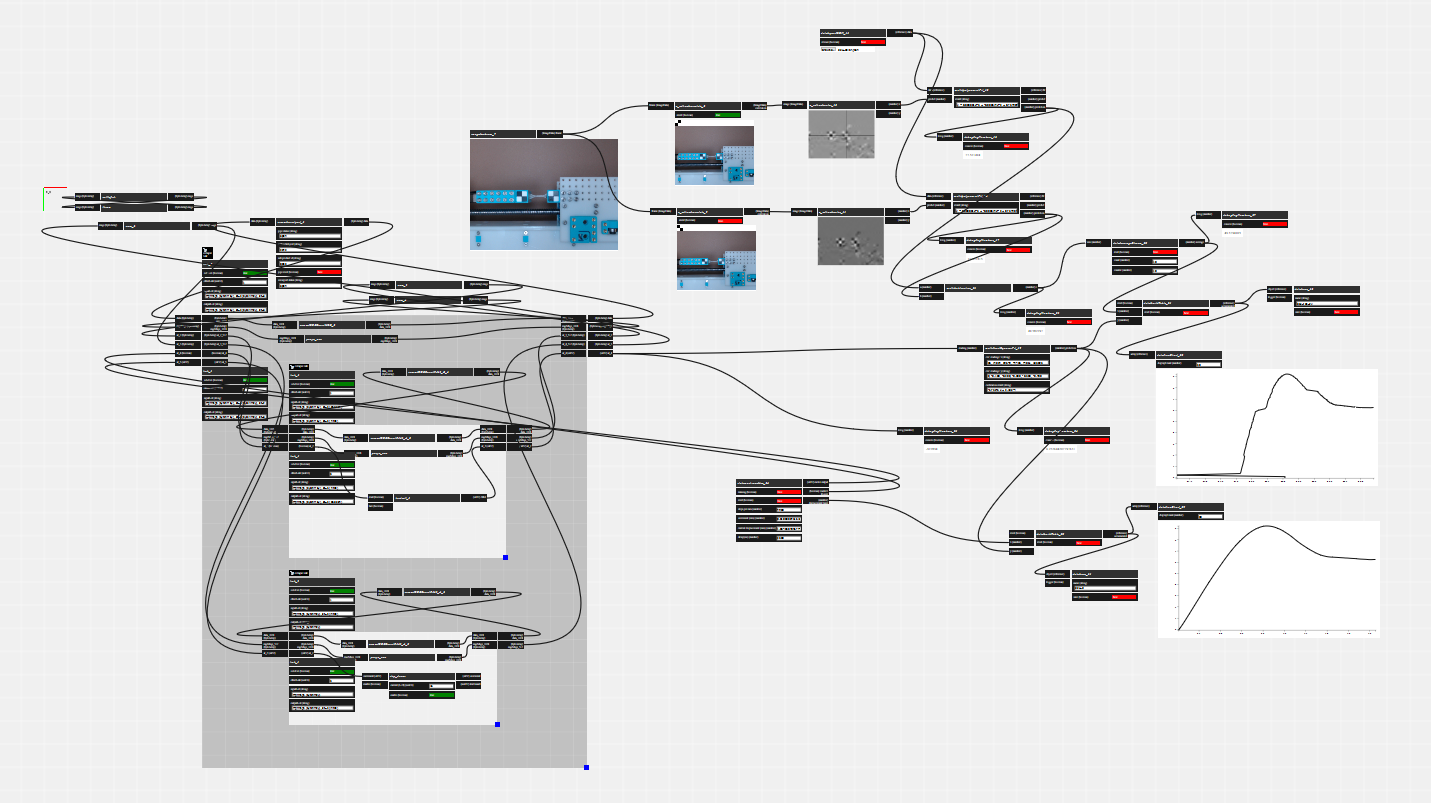

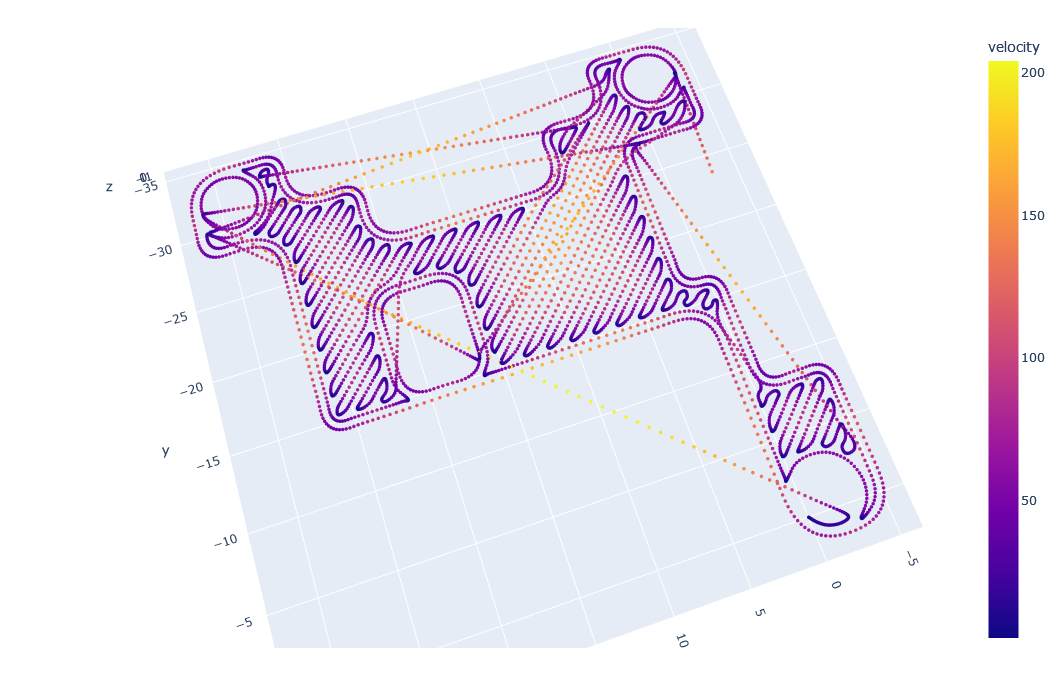

Optimizing path w/ compression model for extrusion (from data) and simple motor models.

Optimizing path w/ compression model for extrusion (from data) and simple motor models.

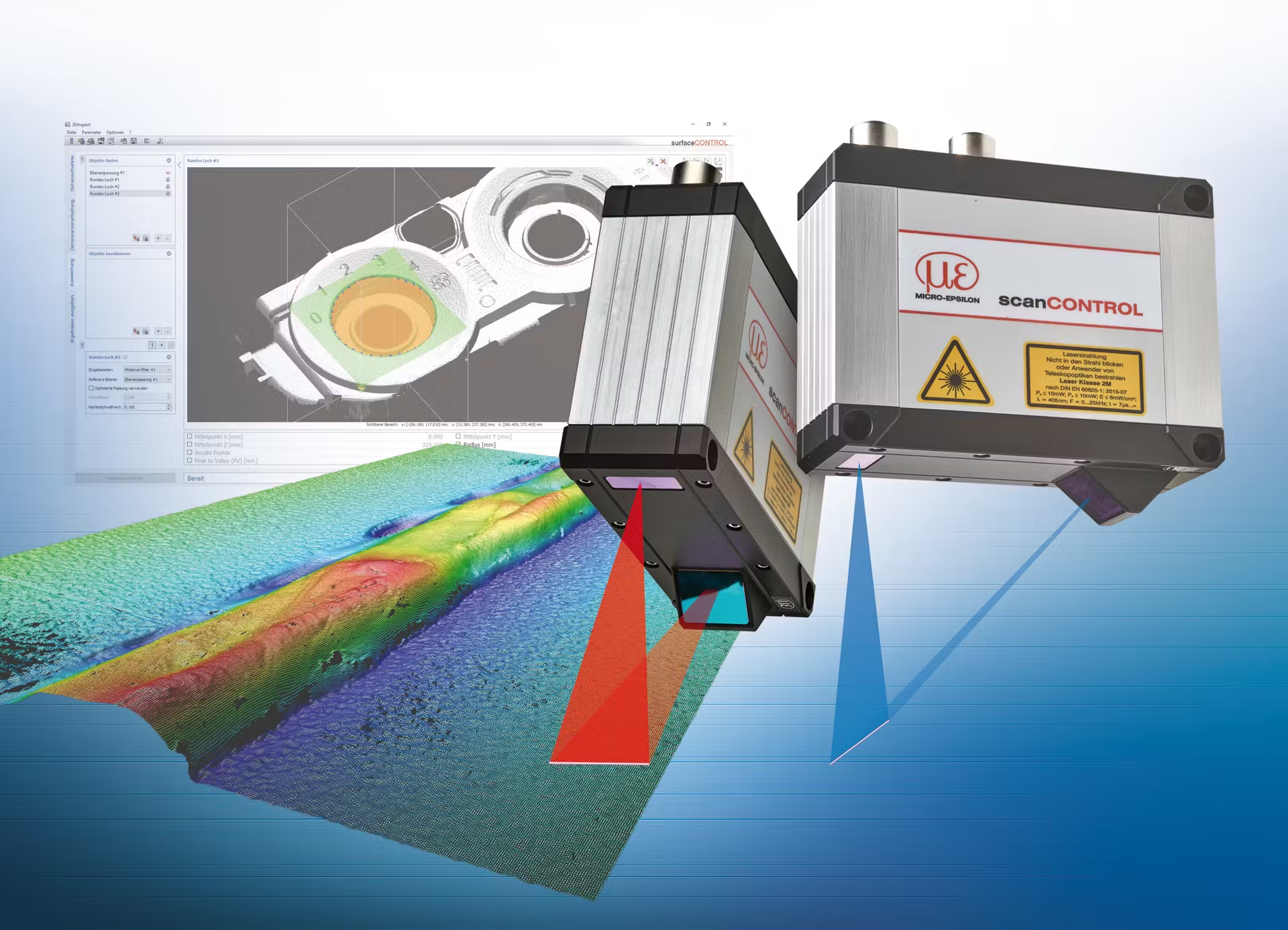

SOTA from Micro

Epsilon

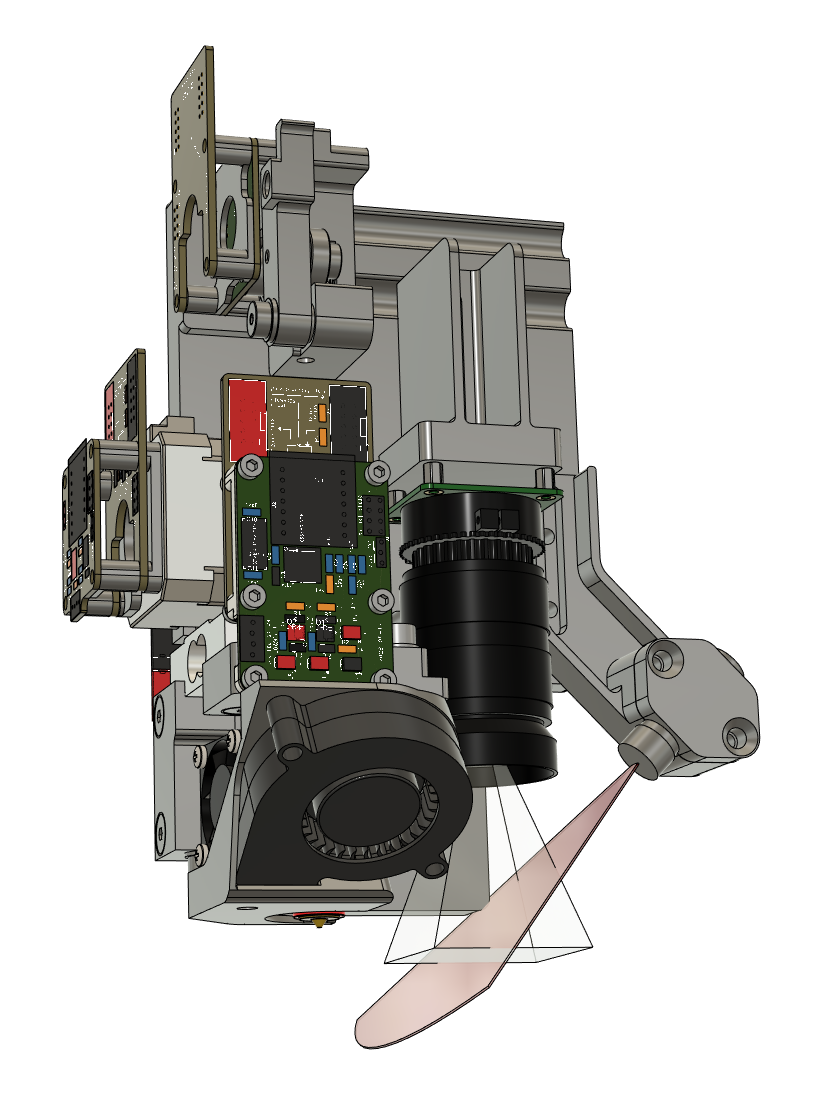

Next Steps: per-layer model refinement via laser-scanned height maps.

Others deploying laser-line scanners for Printer calibration:

Wu, Pinyi. 2024. “Modeling and Feedforward Deposition Control in Fused Filament Fabrication.”

Abbot, Mike. 2023. “Rubedo: A System for Automatically Calibrating Pressure Advance Using Laser Triangulation.” https://github.com/furrysalamander/rubedo.

Wu, Pinyi. 2024. “Modeling and Feedforward Deposition Control in Fused Filament Fabrication.”

Abbot, Mike. 2023. “Rubedo: A System for Automatically Calibrating Pressure Advance Using Laser Triangulation.” https://github.com/furrysalamander/rubedo.

Recycled, Renewable, and Ad-Hoc

in Back to the Future

G21 ; use millimeters

G28 ; run the homing routine

G92 X110 Y120 Z30 ; set current position to (110, 120, 30)

G0 X10 Y10 Z10 F6000 ; "rapid" in *units per minute*

M3 S5000 ; turn the spindle on, at 5000 RPM

G1 Z-3.5 F600 ; plunge from (10, 10, 10) to (10, 10, -3.5)

G1 X20 ; draw a square, go to the right,

G1 Y20 ; go backwards 10mm

G1 X10 ; go to the left 10mm

G1 Y10 ; go forwards 10mm

G1 Z10 ; go up to Z10, exiting the material

M5 ; stop the spindle

G0 X110 Y120 Z30 ; return to the position after homing (at 6000)

A simple GCode program, for a milling machine.

From Formation Plastics.

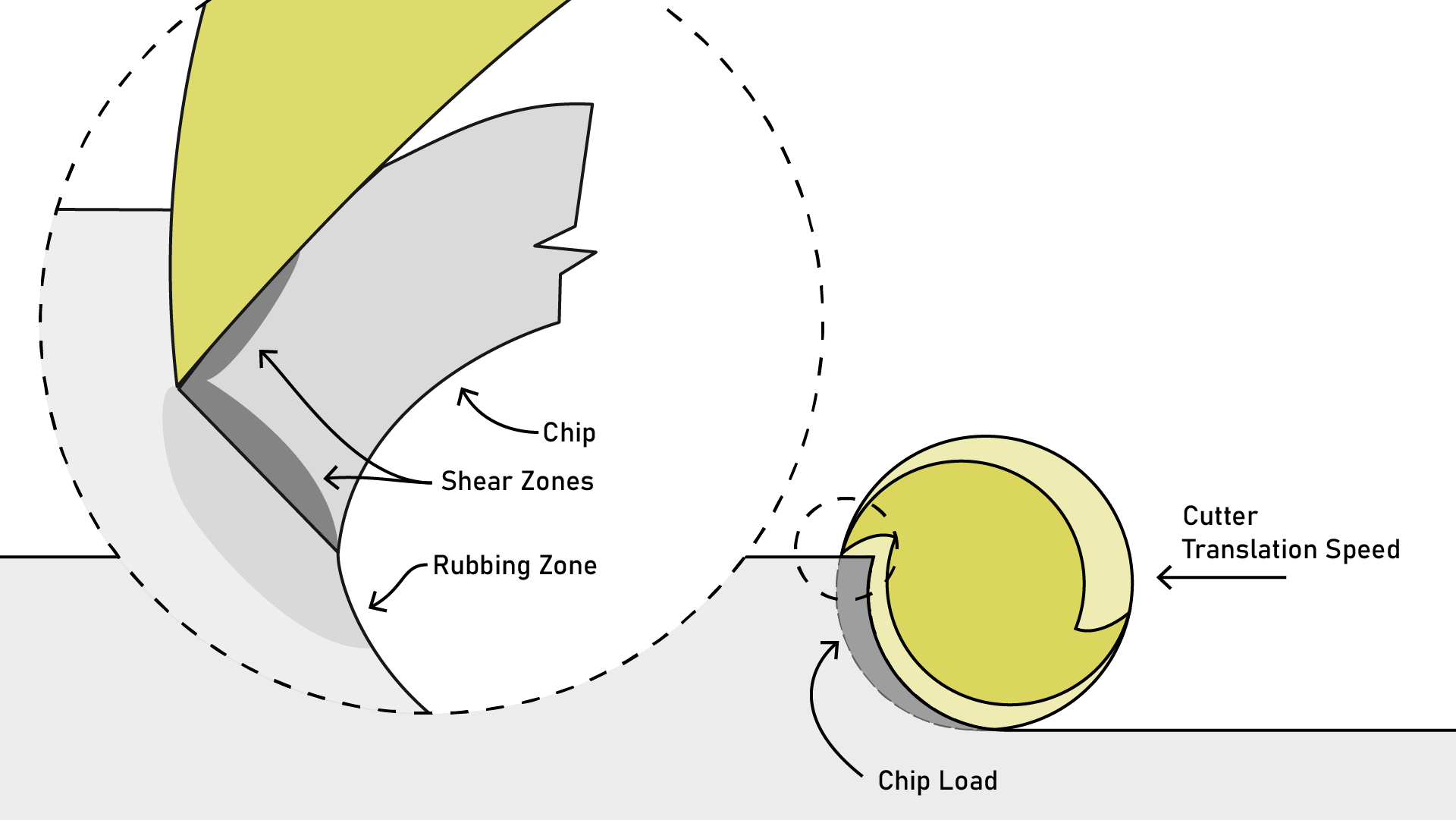

Built Up Edge (BUE) Formation, via YouTube.

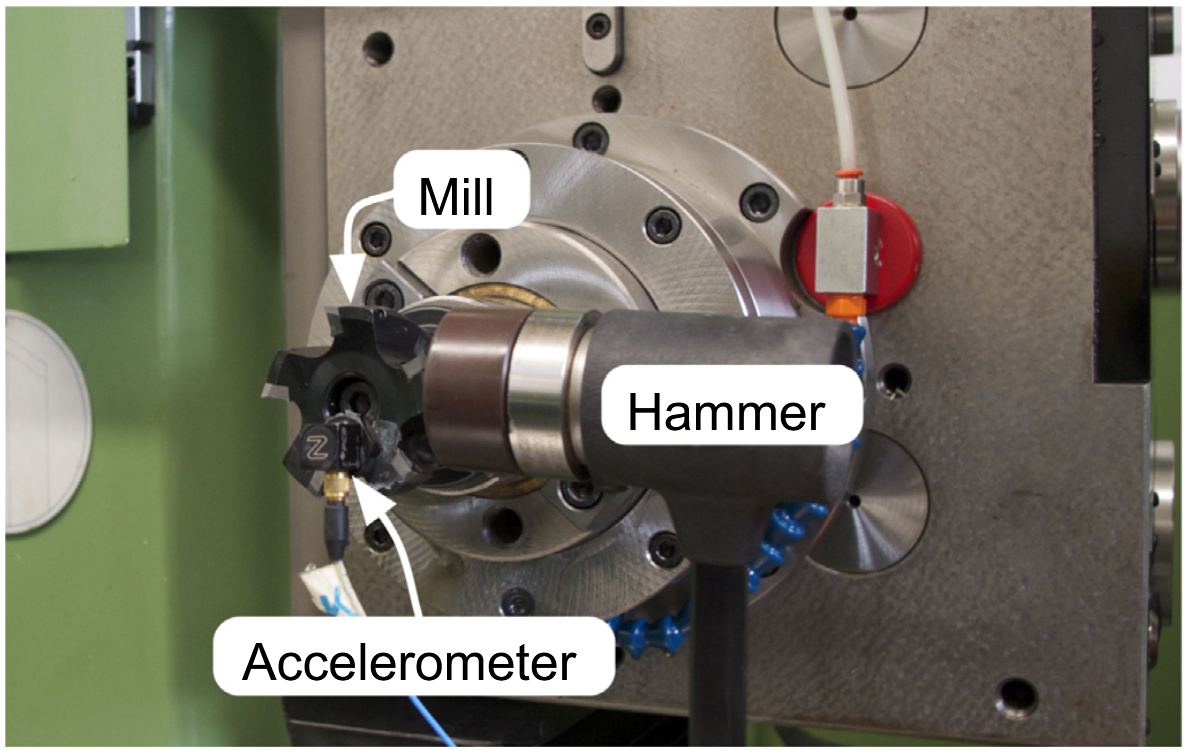

Schmitz, Tony L, and K Scott Smith. 2009. “Machining Dynamics.” Springer, 303.

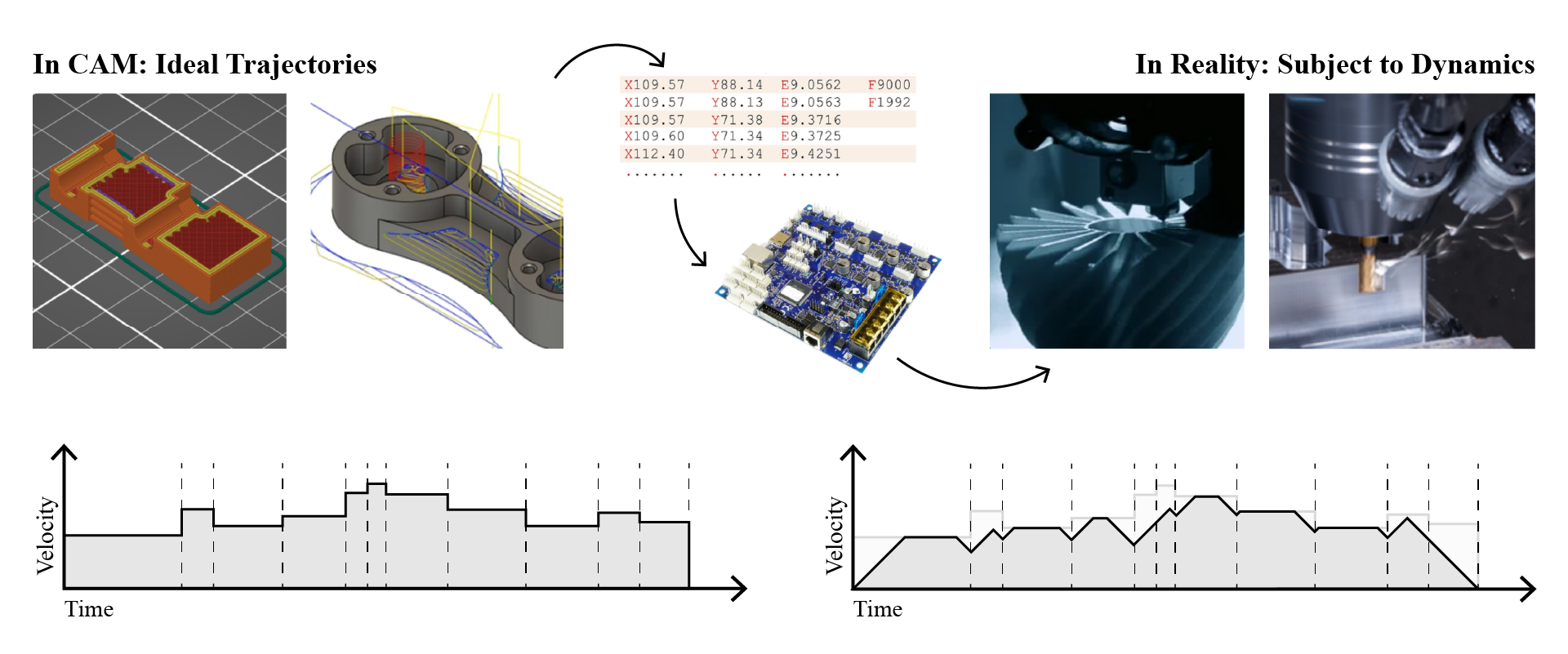

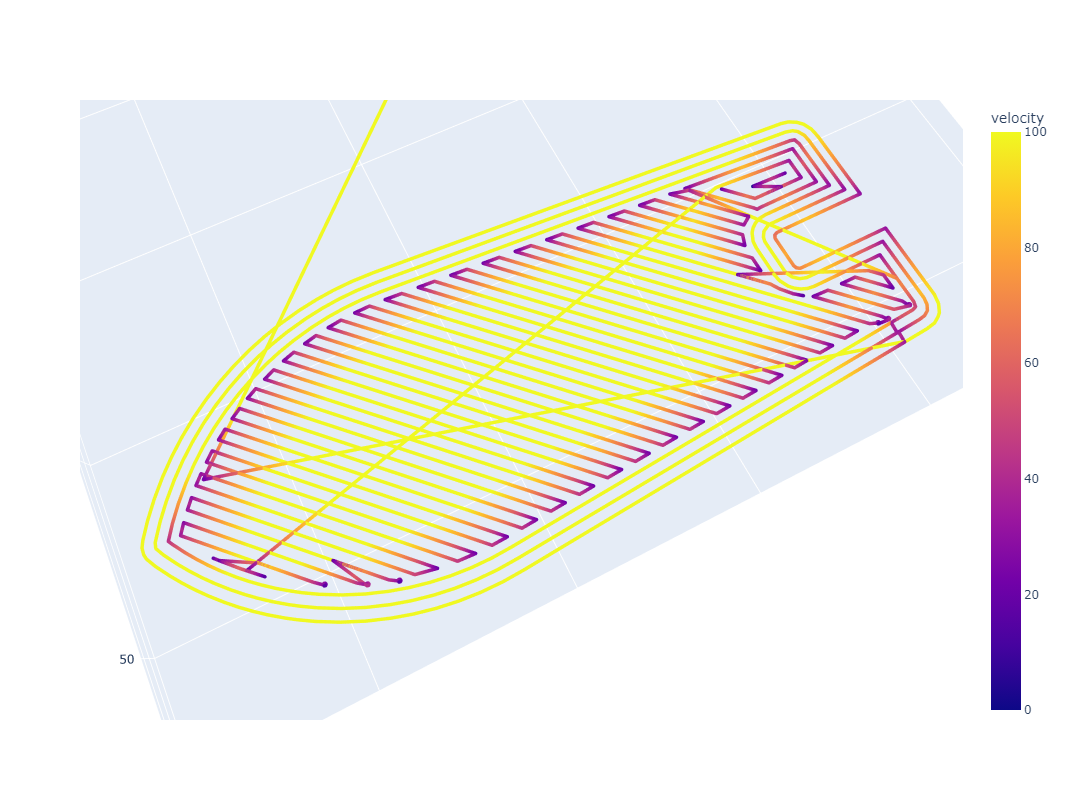

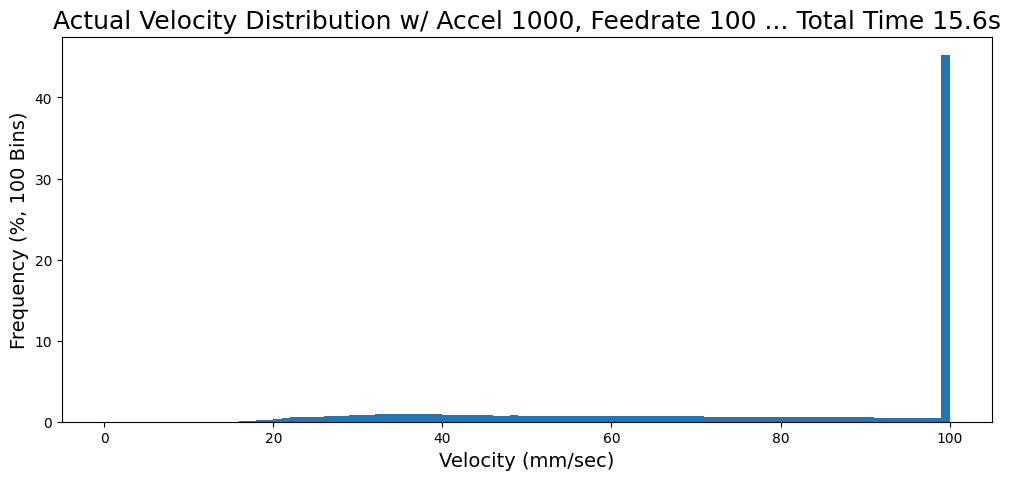

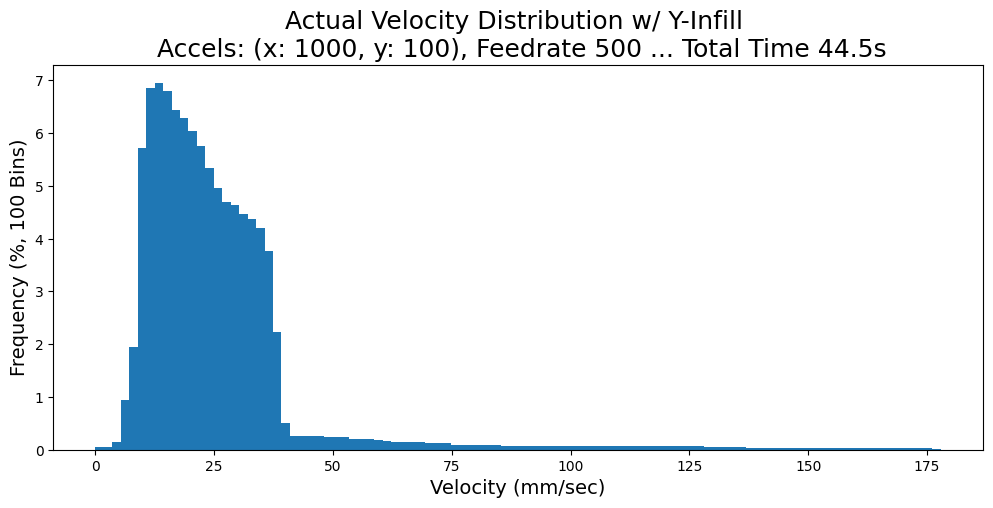

100mm/sec Feedrate Parameter,

1000mm/sec2 Acceleration Limit

1000mm/sec2 Acceleration Limit

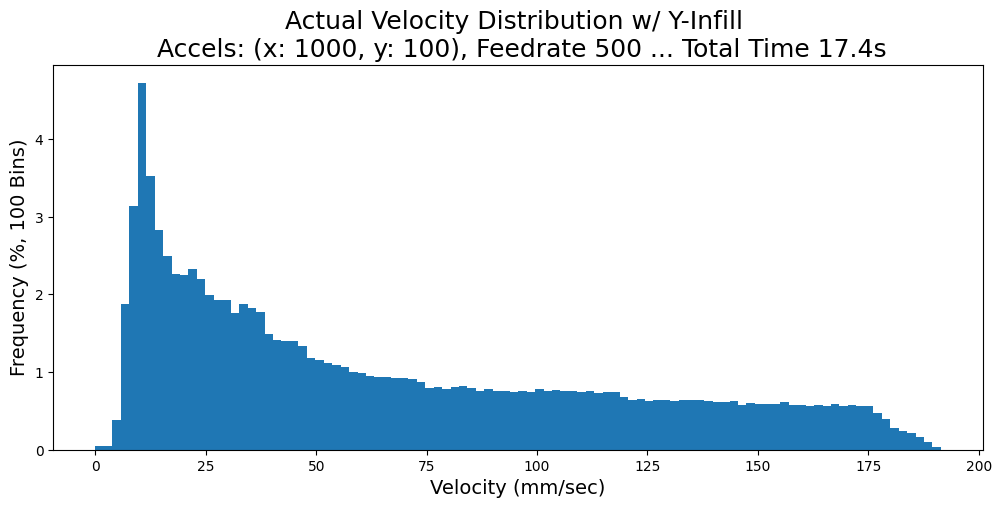

500mm/sec Feedrate Parameter

1000mm/sec2 Acceleration Limit

1000mm/sec2 Acceleration Limit

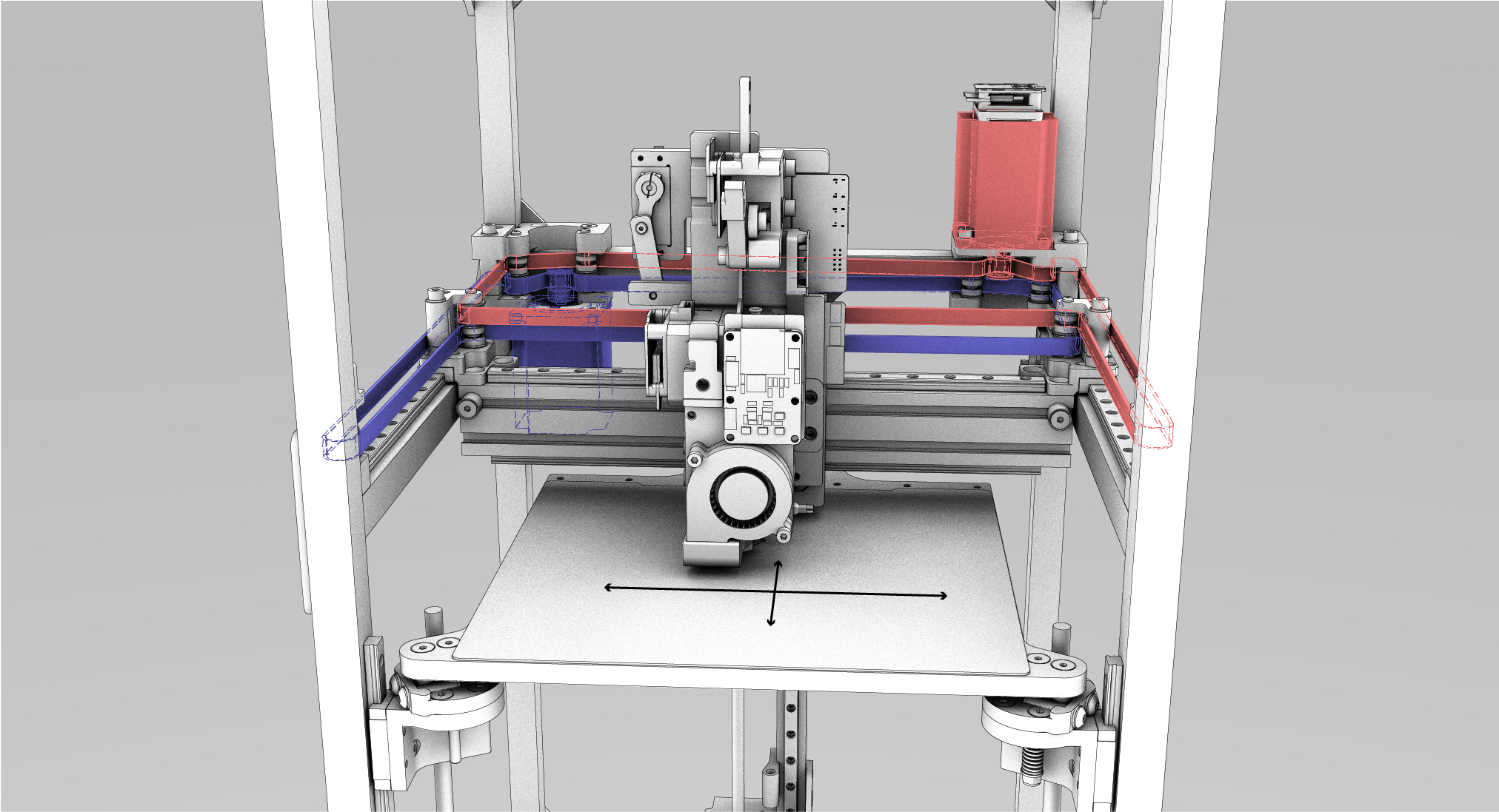

Moyer, Ilan. 2024. “CoreXY: A Mechanism for Motion Control in 3D Printers and CNC Machines.” https://corexy.com/.

Motion Perpendicular to Dominant Axis

Motion Aligned to Dominant Axis

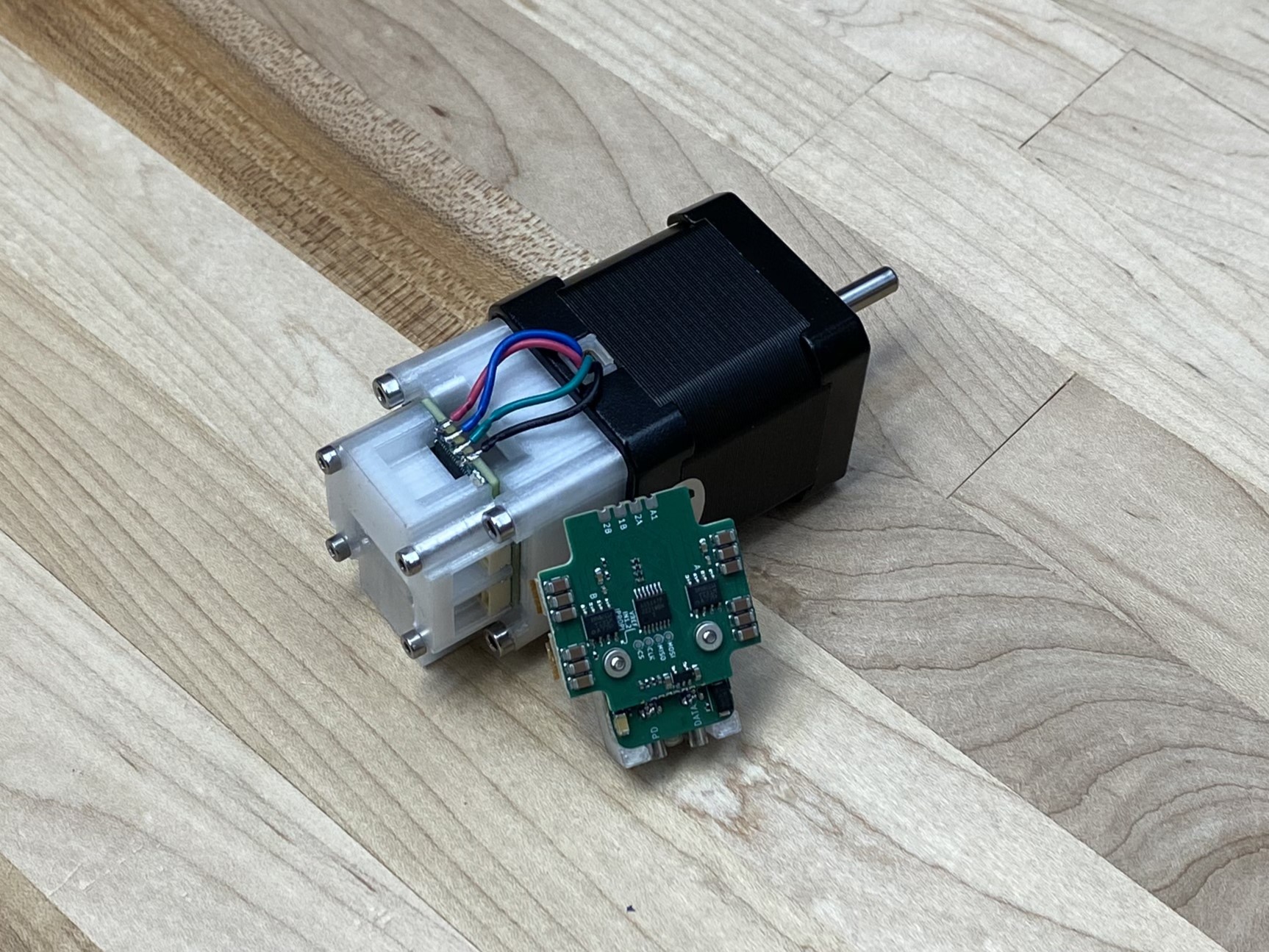

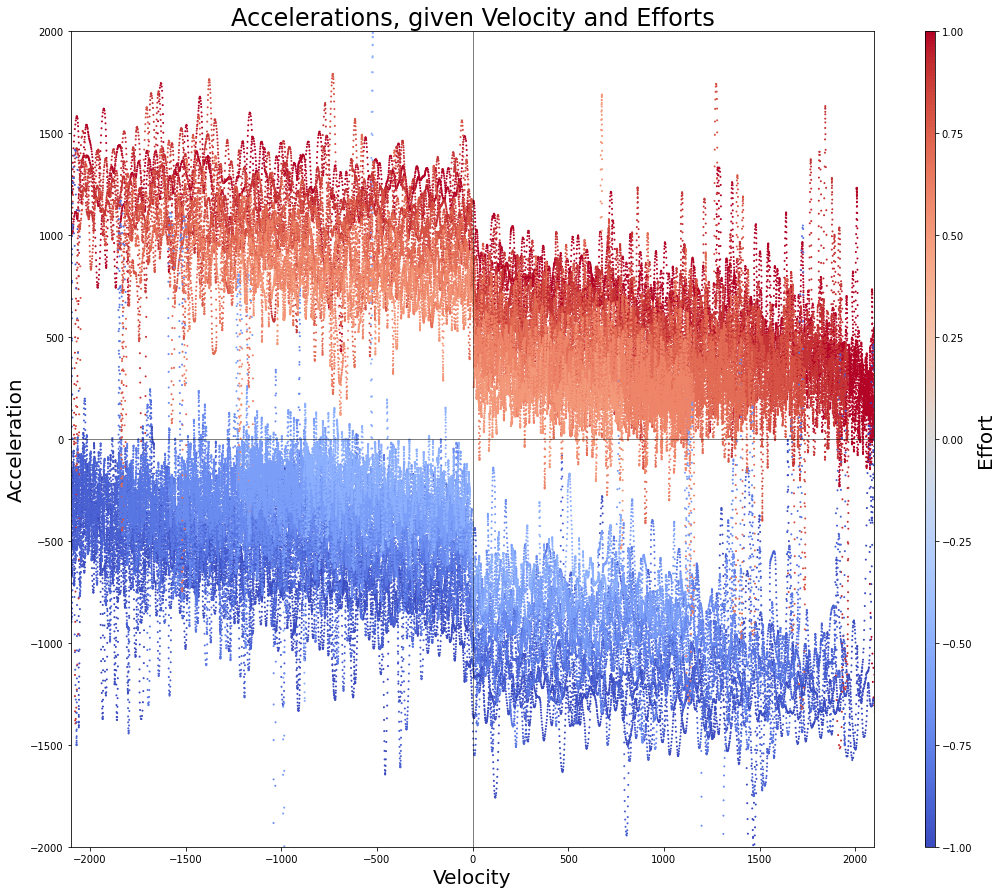

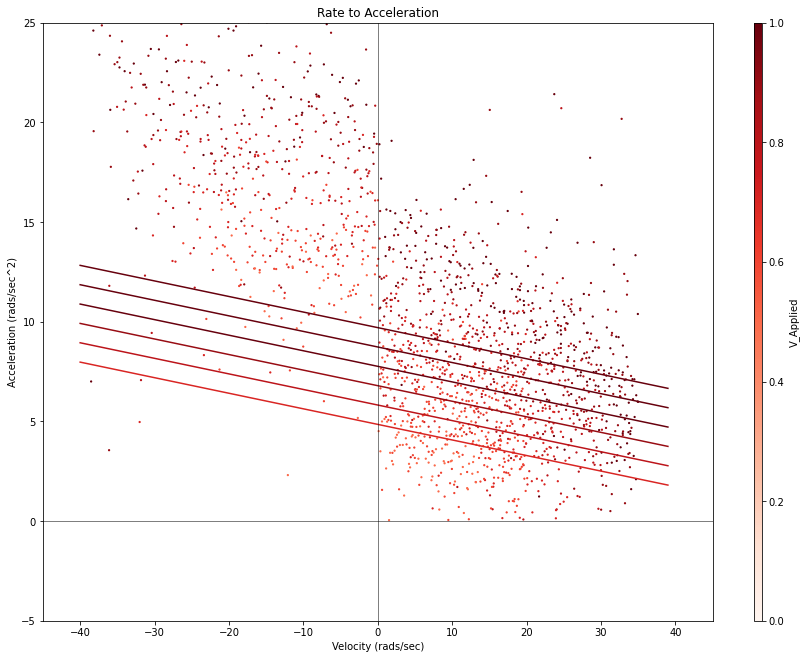

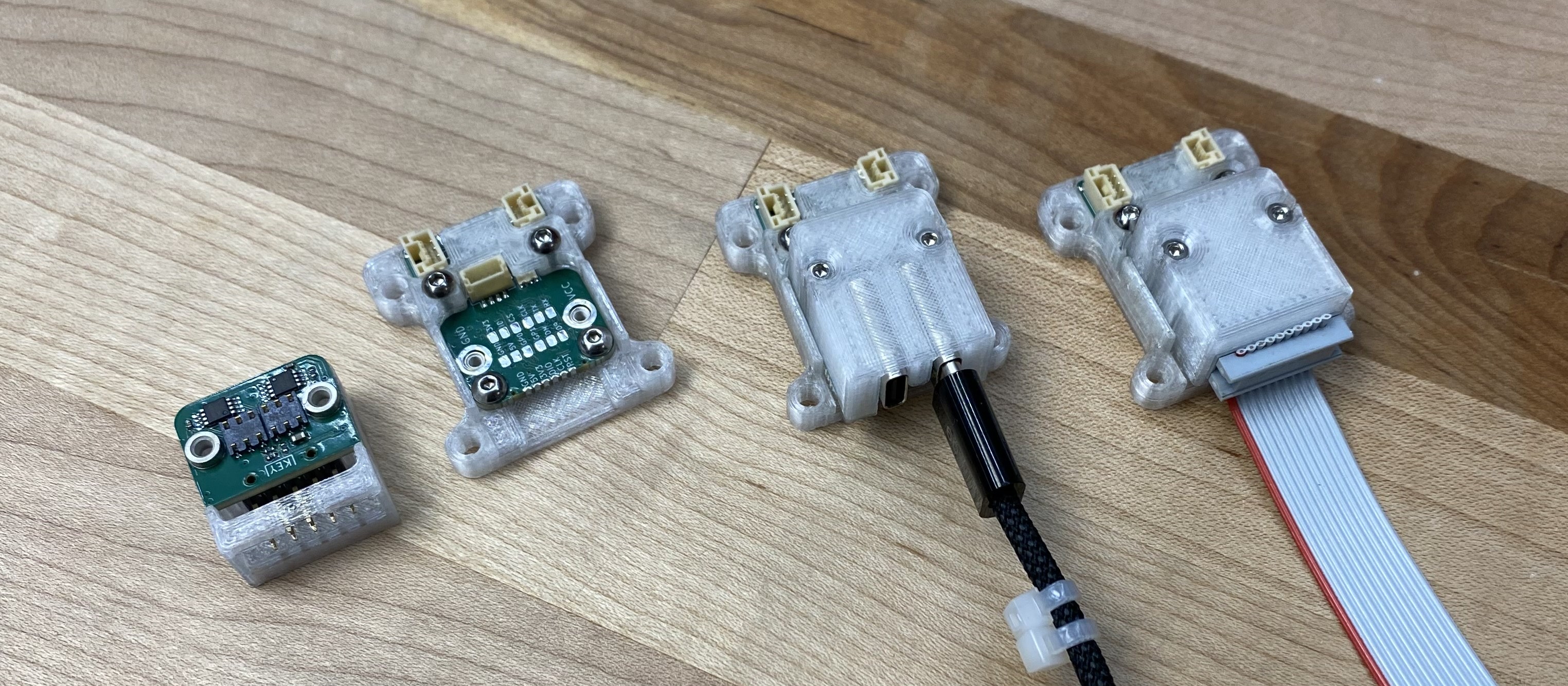

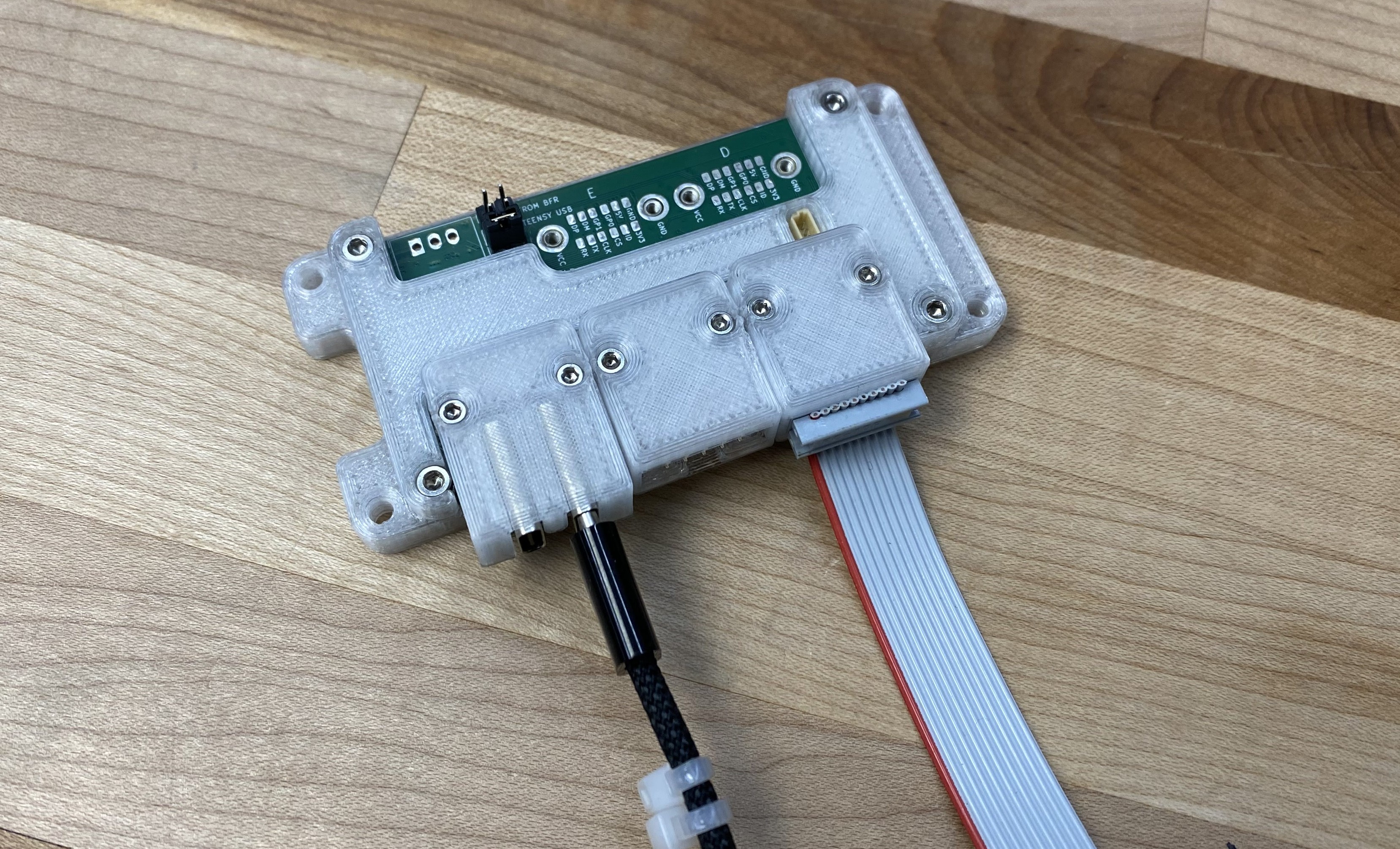

Closed-Loop Stepper Driver w/ 14-bit Encoder and Current Measurement

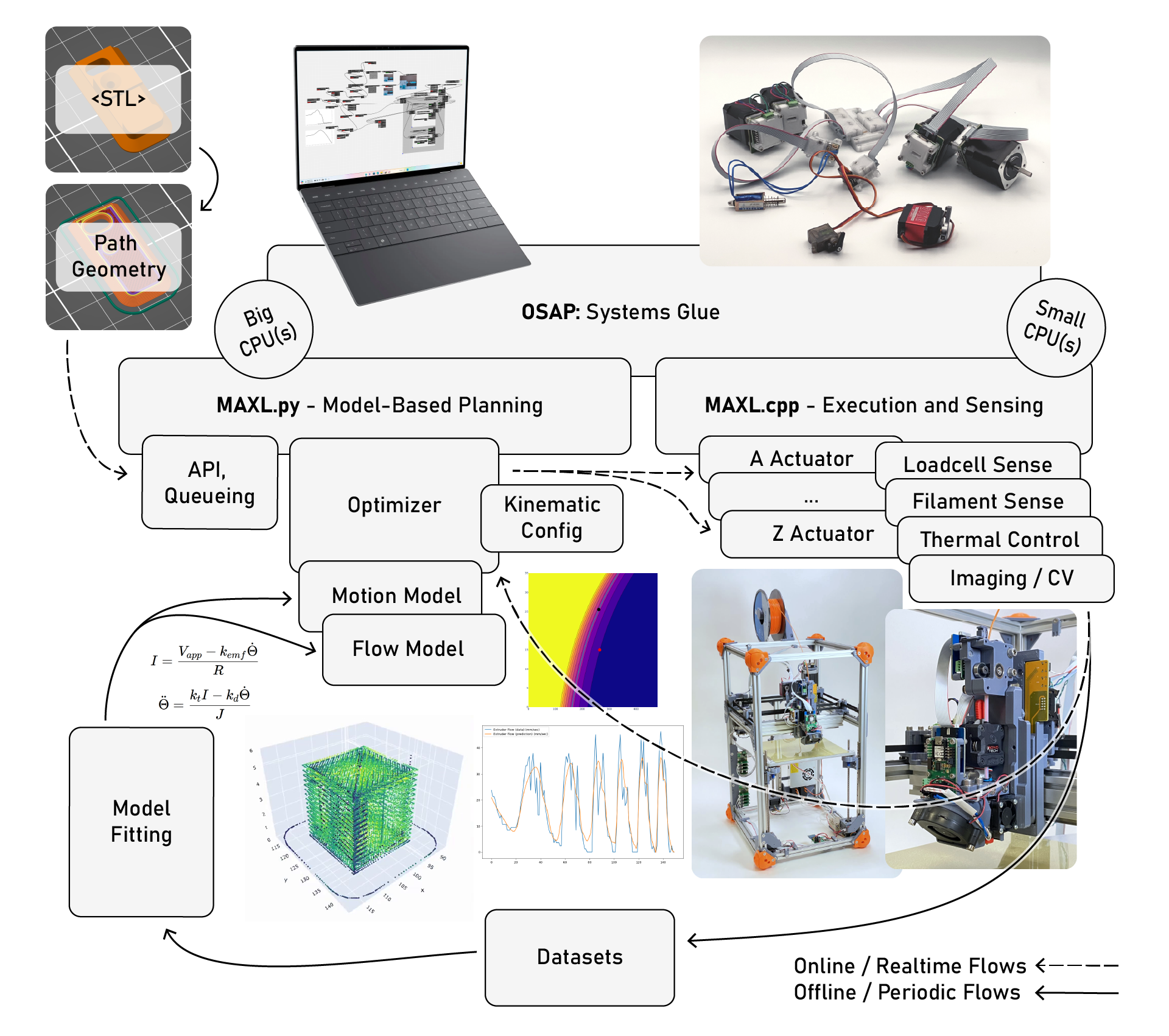

$$I = \frac{V_{app} - k_{emf}\dot{\Theta}}{R}$$

$$\ddot{\Theta} = \frac{k_tI - k_d\dot{\Theta}}{J}$$

Optimizing path w/ compression model for extrusion (from data) and simple motor models.

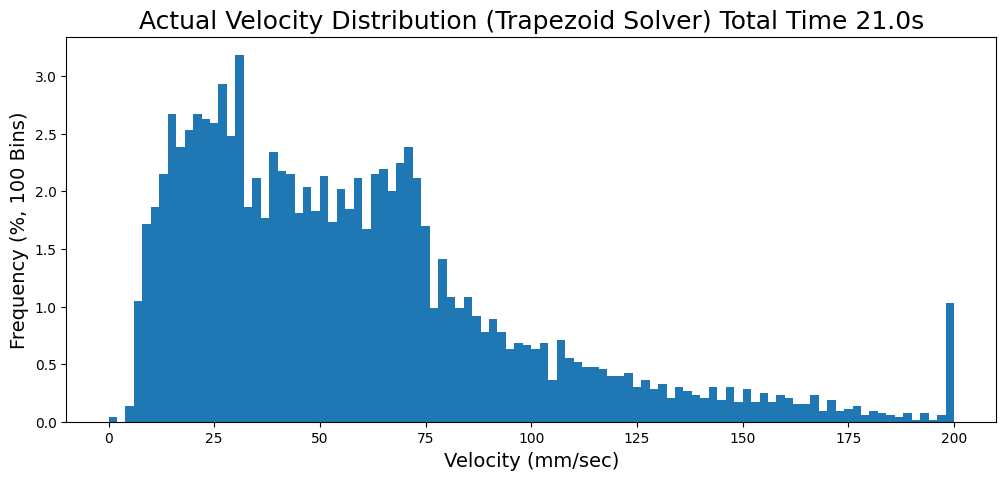

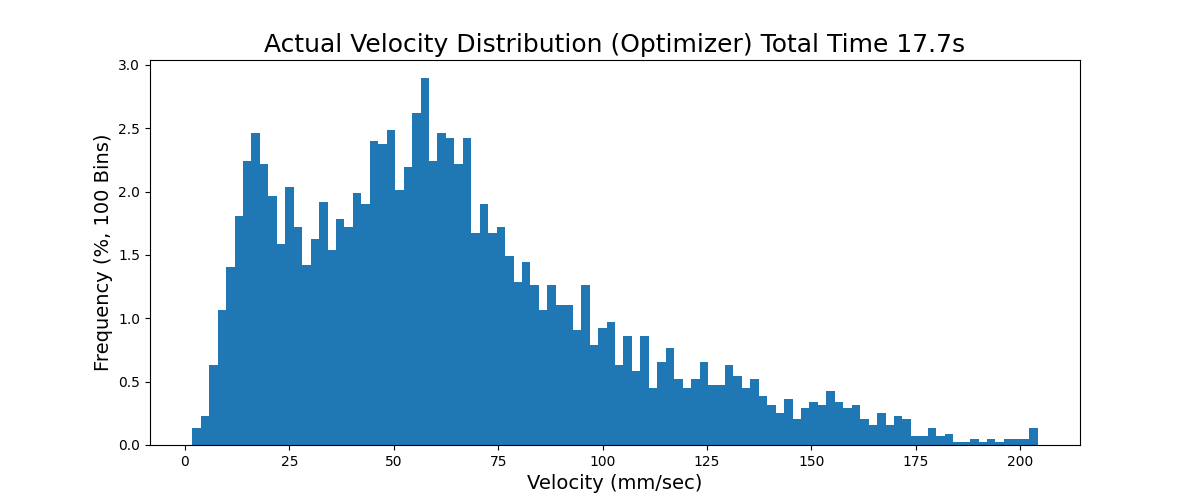

Path Solved with Trapezoids (common in SOTA)

Path Solved with MPC (this work) (14% speedup)

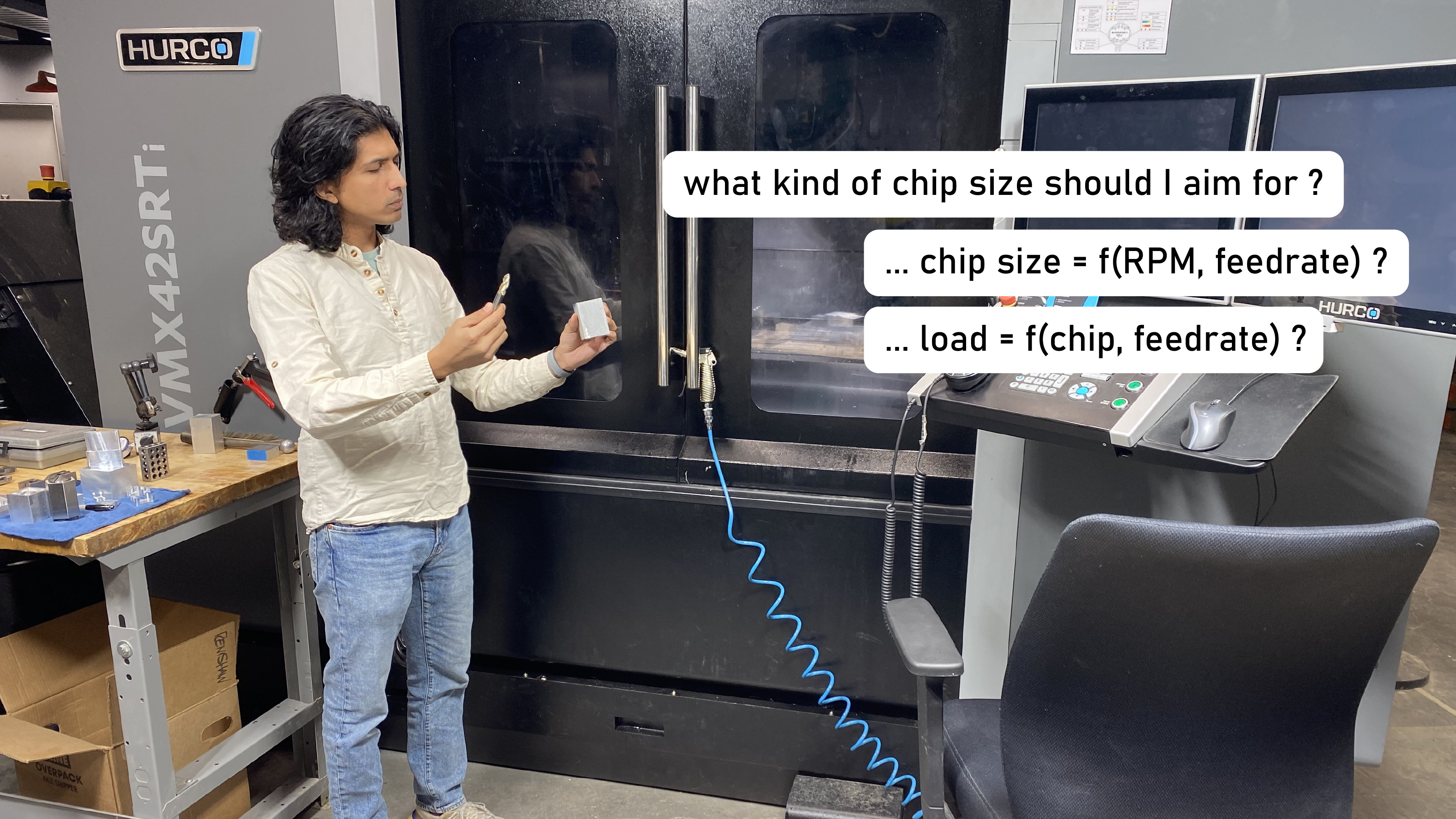

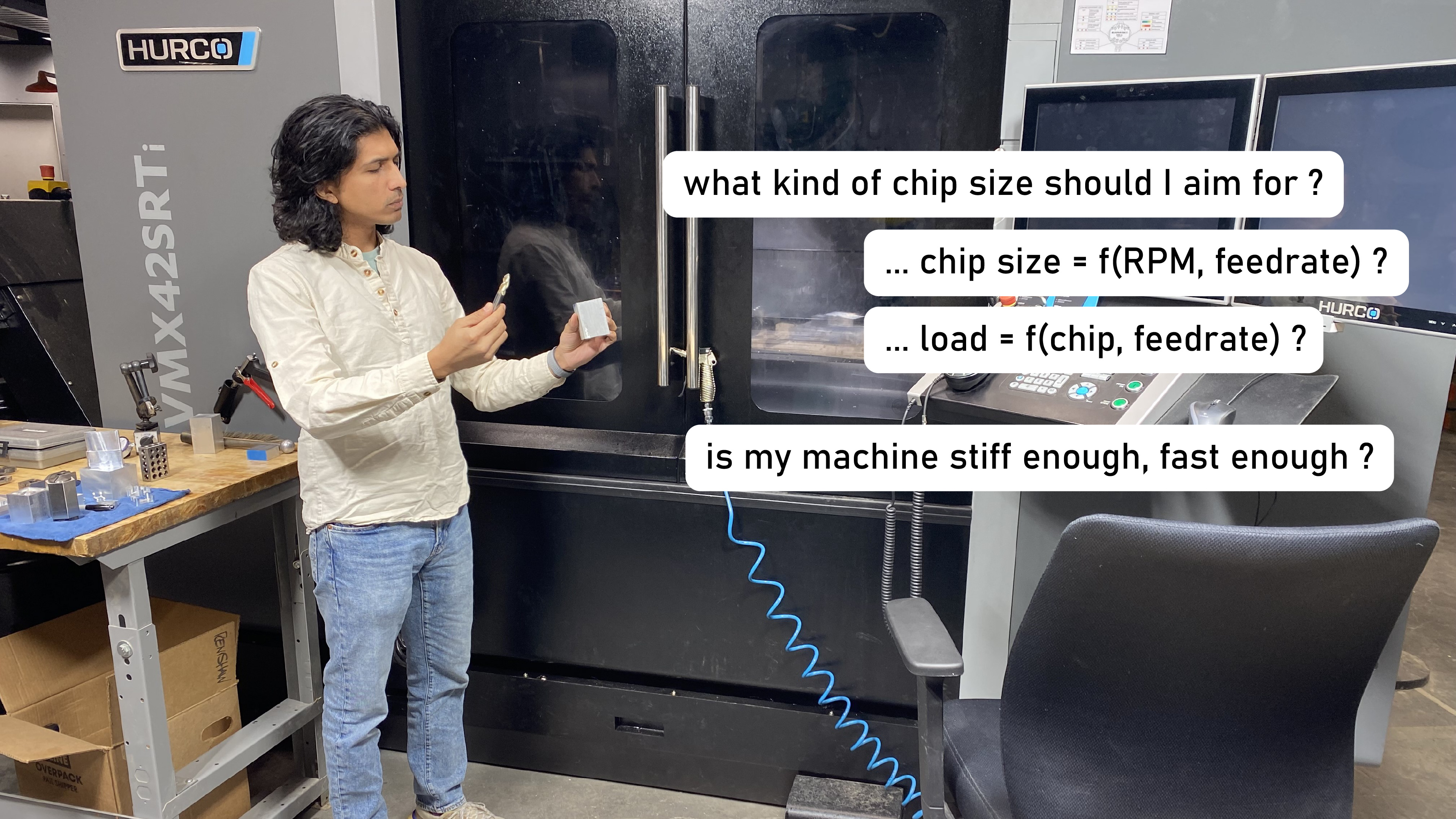

Cutting Force per unit of Depth

$$F_t = K_{tc}ah(\theta) + K_{te}a$$

$$F_r = K_{rc}ah(\theta) + K_{re}a$$

$\theta$ is chip thickness$K_{tc}, K_{rc}$ are cutting force coefficients

$K_{te}, K_{re}$ are edge force coefficients

Dunwoody, Keith. Automated identification of cutting force coefficients and tool dynamics on

CNC machines. Diss. University of British Columbia, 2010.

Sharma, Chetan. Automatic modeling of machining processes. Diss. Massachusetts Institute of

Technology, 2021.

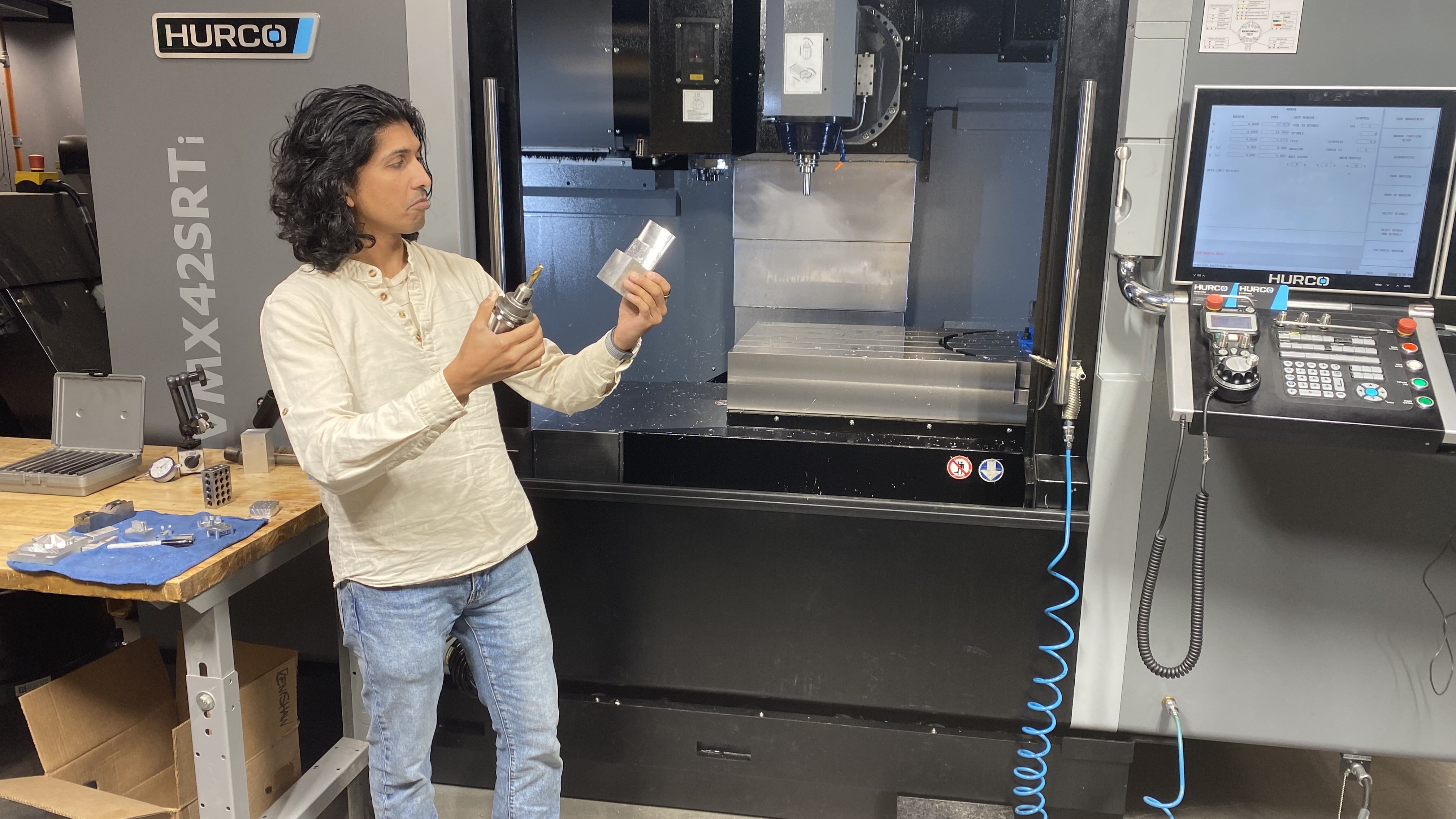

SOTA Resonance Testing

Bort, Carlos Maximiliano Giorgio, Marco Leonesio, and Paolo Bosetti. "A model-based adaptive

controller for chatter mitigation and productivity enhancement in CNC milling machines."

Robotics and Computer-Integrated Manufacturing 40 (2016): 34-43.

... from publication in-progress

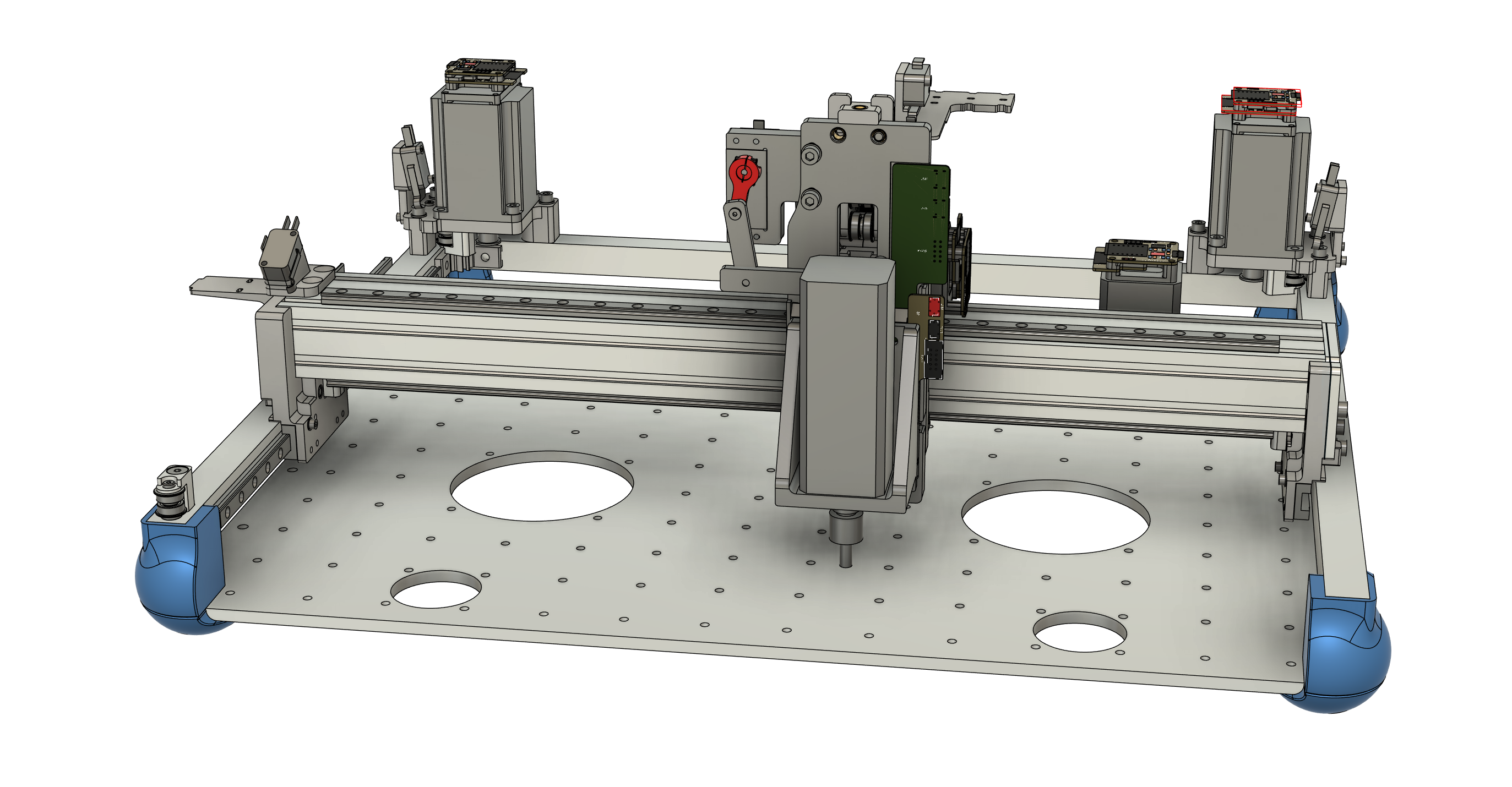

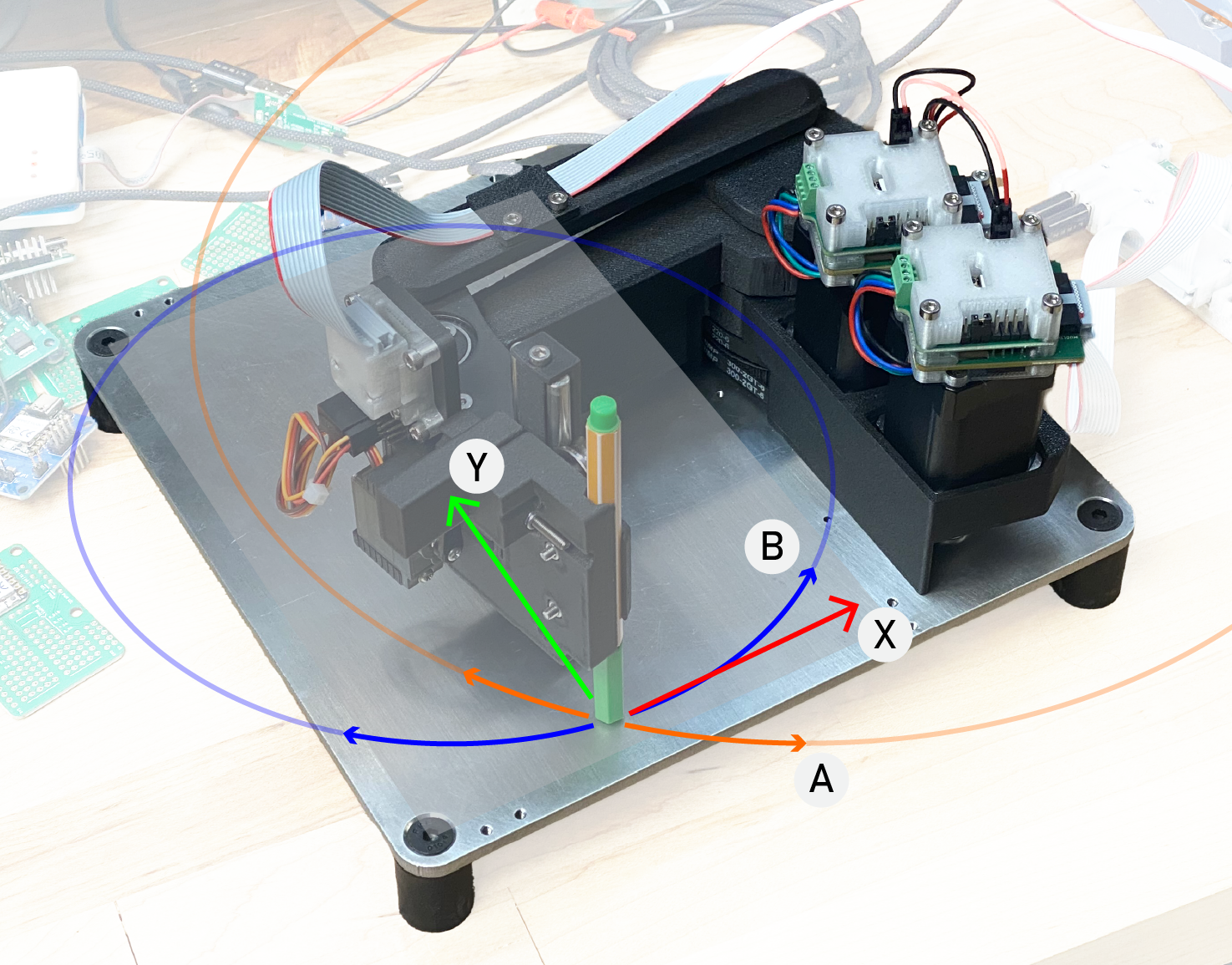

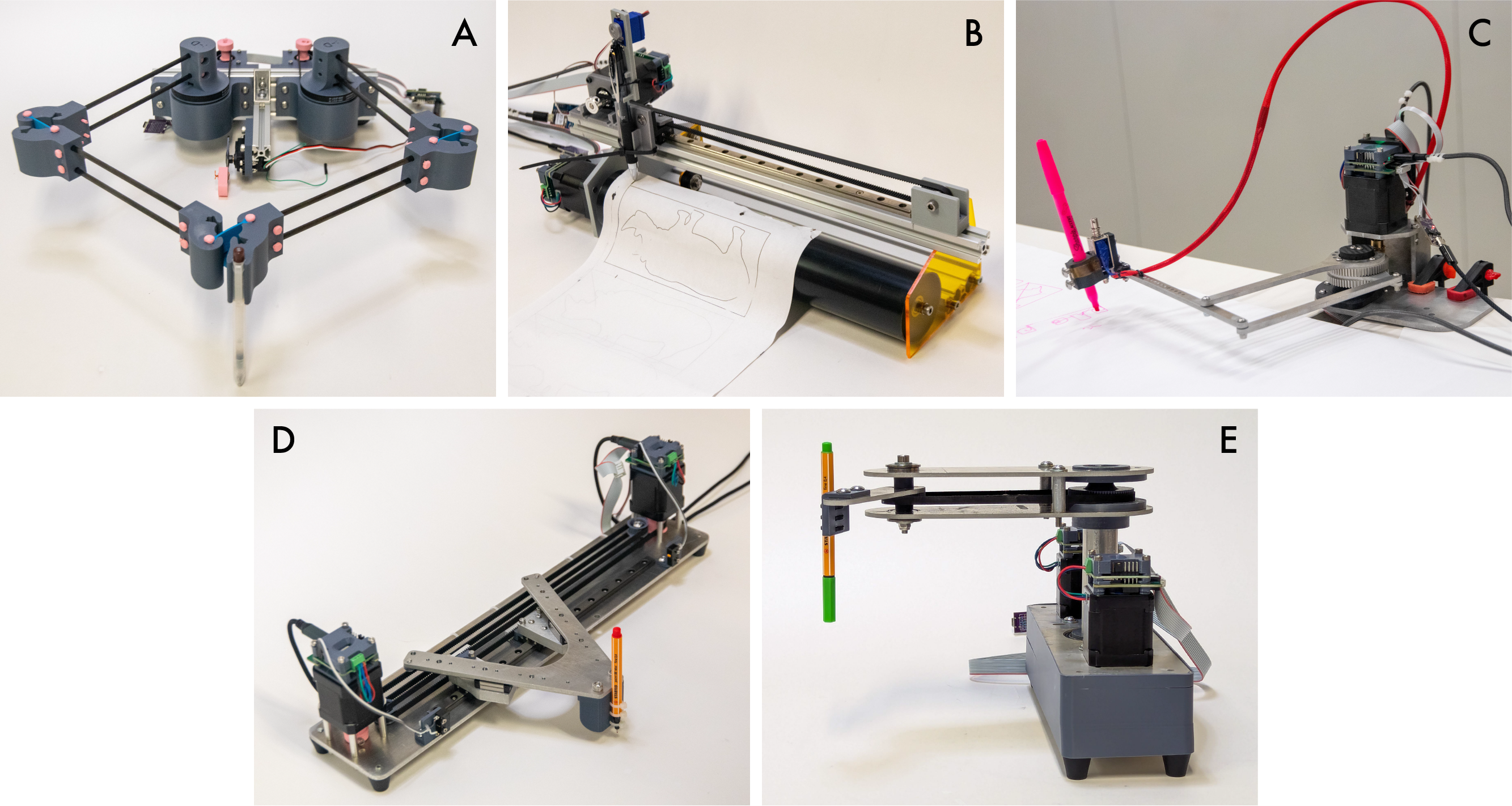

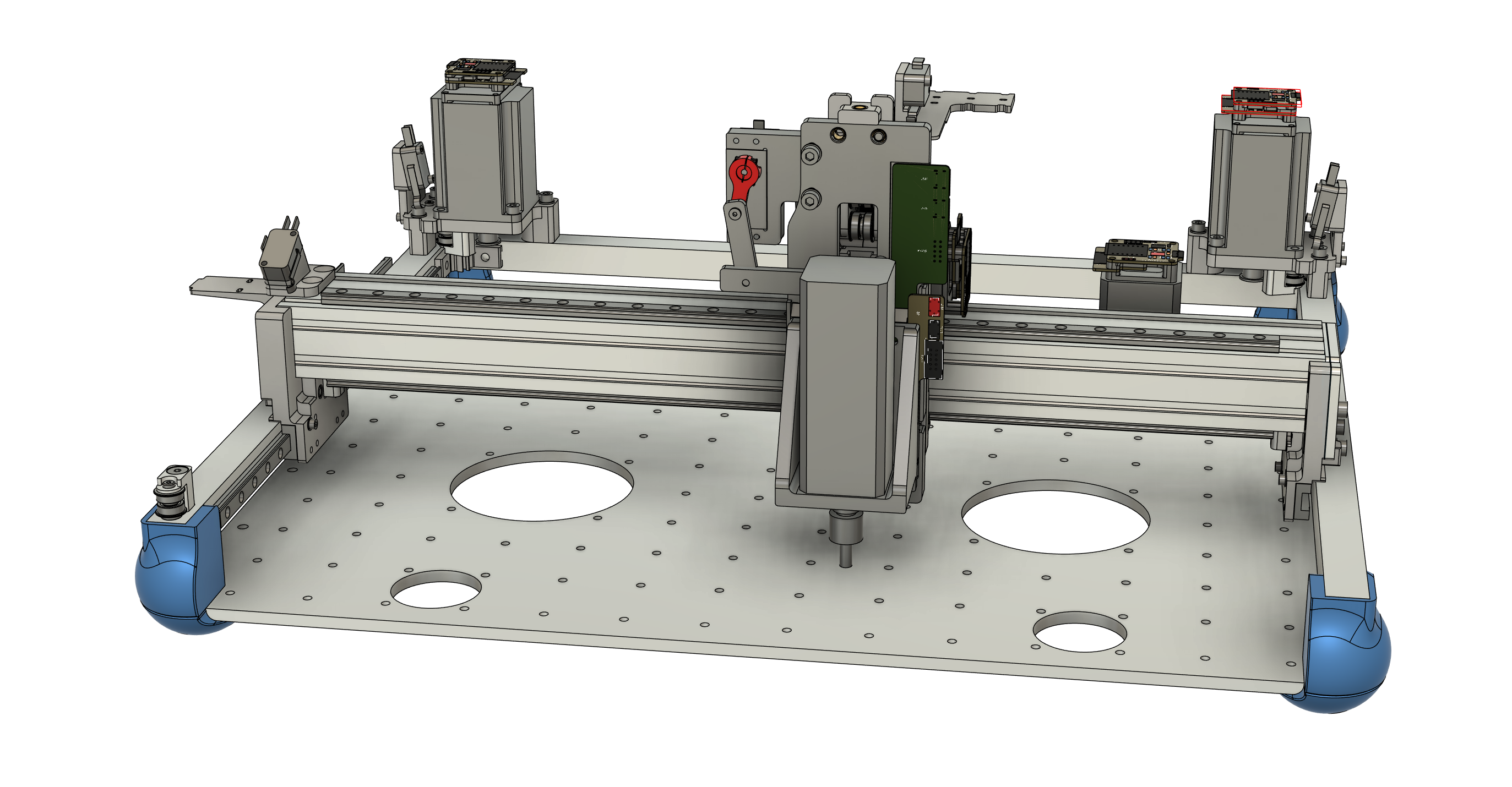

Plotter Comp 2025

Parameters:

January 28-31 @ MIT EDS Shop

4-6 Machine Builders

Materials and Controllers Provided

January 28-31 @ MIT EDS Shop

4-6 Machine Builders

Materials and Controllers Provided

Constraints:

Comp Regulation Pens (Stabilo Mini 88)

100x100mm Drawing Area

Comp Regulation Pens (Stabilo Mini 88)

100x100mm Drawing Area

Evaluation (Participants):

10x Comp Regulation SVG's

Speed

Precision

Accuracy

BOM Cost

Fabrication Complexity

10x Comp Regulation SVG's

Speed

Precision

Accuracy

BOM Cost

Fabrication Complexity

Evaluation (MAXL):

Heterogeneity of Kinematics

Performance

Ease of Setup

Inspectability, Debuggability, Extensibility

Heterogeneity of Kinematics

Performance

Ease of Setup

Inspectability, Debuggability, Extensibility

G21

G28

G92 X110 Y120 Z30

G0 X10 Y10 Z10 F6000

M3 S5000

G1 Z-3.5 F600

G1 X20

G1 Y20

G1 X10

G1 Y10

G1 Z10

M5

G0 X110 Y120 Z30

await machine.home()

machine.set_current_position([110, 120, 30])

await machine.goto_now([10, 10, 10], target_rate = 100)

await spindle.await_rpm(5000)

await machine.goto_via_queue([10, 10, -3.5], target_rate = 10)

await machine.goto_via_queue([20, 10, -3.5], target_rate = 10)

await machine.goto_via_queue([20, 20, -3.5], target_rate = 10)

await machine.goto_via_queue([20, 10, -3.5], target_rate = 10)

await machine.goto_via_queue([10, 10, 10], target_rate = 10)

await spindle.await_rpm(0)

await machine.goto_now([110, 120, 30], target_rate = 100)

The same basic program, articulated as GCode, or as calls to our Python API.

Moyer, Ilan Ellison. A gestalt framework for virtual machine control of automated tools. Diss.

Massachusetts Institute of Technology, 2013.

Peek, Nadya Meile. Making machines that make: object-oriented hardware meets object-oriented software. Diss. Massachusetts Institute of Technology, 2016.

Peek, Nadya Meile. Making machines that make: object-oriented hardware meets object-oriented software. Diss. Massachusetts Institute of Technology, 2016.

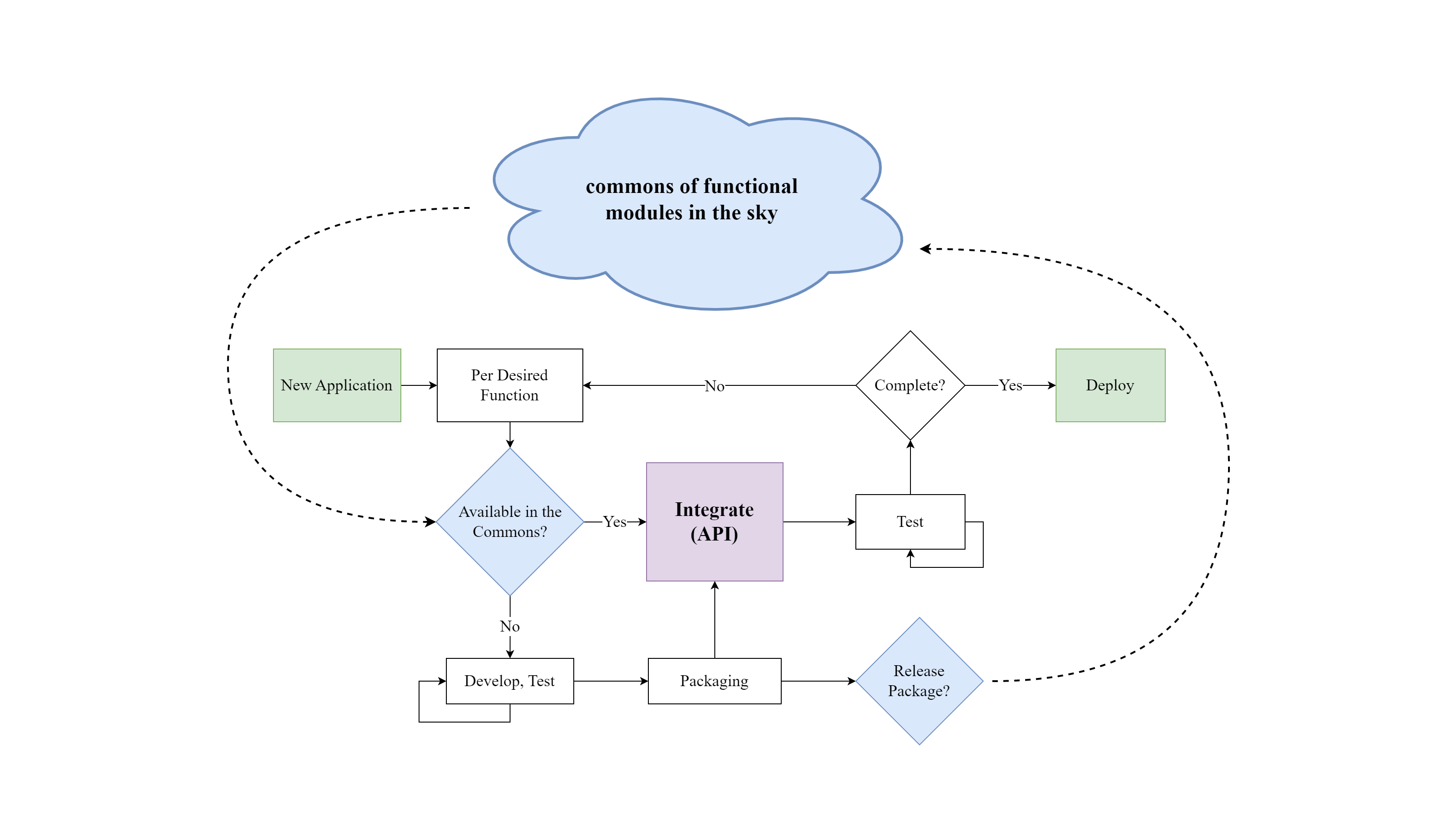

We can bottle complex routines into higher level APIs...

await machine.route_shape(svg = "target_file/file.svg", material = "plywood, 3.5mm")

And we can easily inspect some lower levels:

async def home(self, switch: Callable[[], Awaitable[Tuple[int, bool]]], rate: float = 20, backoff: float = 10):

# move towards the switch at `rate`

self.goto_velocity(rate)

# await the switch signal

while True:

time, limit = await switch()

if limit:

# get the DOF's position as reconciled with the limit switch's actual trigger time

states = self.get_states_at_time(time)

pos_at_hit = states[0]

# stop once we've hit the limit

await self.halt()

break

else:

await asyncio.sleep(0)

# backoff from the switch

await self.goto_pos_and_await(pos_at_hit + backoff)

Firmwares contain function implementations.

// in hbridge firmware

float readAvailableVCC(void){

const float r1 = 10000.0F;

const float r2 = 470.0F;

// it's this oddball, no-init ADC stuff,

// teensy is 10-bits basically, y'all

uint16_t val = analogRead(PIN_SENSE_VCC);

// convert to voltage,

float vout = (float)(val) * (3.3F / 1024.0F);

// that's at 10k - sense - 470r - gnd,

// vout = (vcc x r2) / (r1 + r2)

// (vout * (r1 + r2)) / r2 = vcc

float vcc = (vout * (r1 + r2)) / r2;

return vcc;

}

// one line to generate an interface

BUILD_RPC(readAvailableVCC, "", "");

We can access those from other contexts

via proxy classes.

# auto-generated proxy,

class HBridgeProxy:

# ...

async def read_available_vcc(self) -> float:

result = await self._read_available_vcc_rpc.call()

return cast(float, result)

# ...

These interfaces are generated automatically, using information

provided by the firmware.

We can use those interfaces to author, debug and modify high-level logic without mucking

about in hardware.

# discover all devices

system_map = await osap.netrunner.update_map()

# build a proxy, check existence

hbridge = HbridgeSamd21DuallyProxy(osap, "hbridge_dually")

try:

await hbridge.begin()

except NameError:

print("no hbridge found, check connections...")

print("... request voltage")

await hbridge.set_pd_request_voltage(15)

print("... await voltage")

while True:

vcc_avail = await hbridge.read_available_vcc()

print(F"avail: ${vcc_avail:.2f}")

if vcc_avail > 14.0:

break

print("pulse...")

for _ in range(100):

print("...")

await hbridge.pulse_bridge(2.0, 1000)

await asyncio.sleep(1.75)

await hbridge.pulse_bridge(-1.0, 50)

await asyncio.sleep(1)

print("... done!")

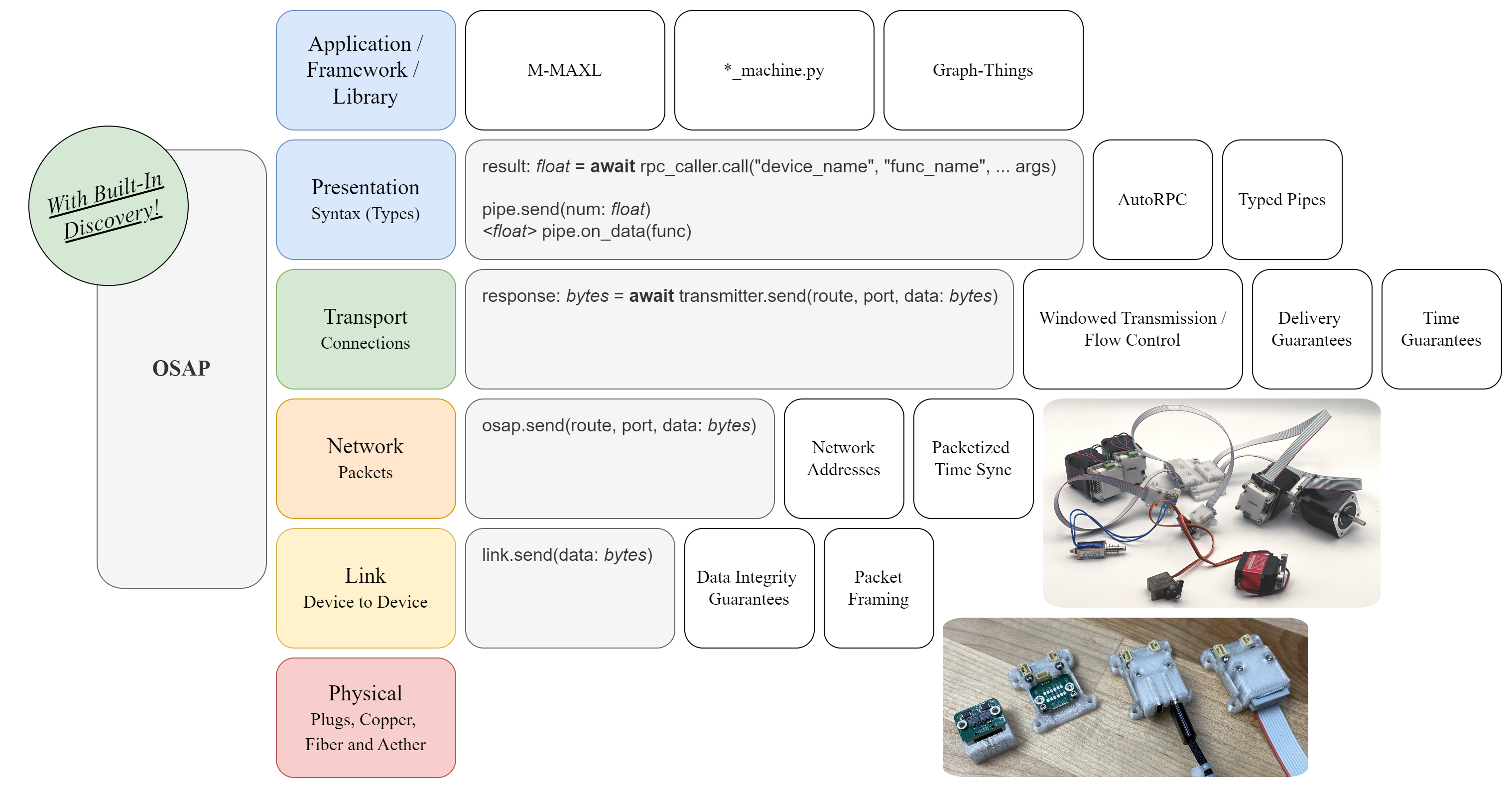

Automatic generation of software interfaces: single-source-of-truth, self-describing modular devices

for distributed systems.

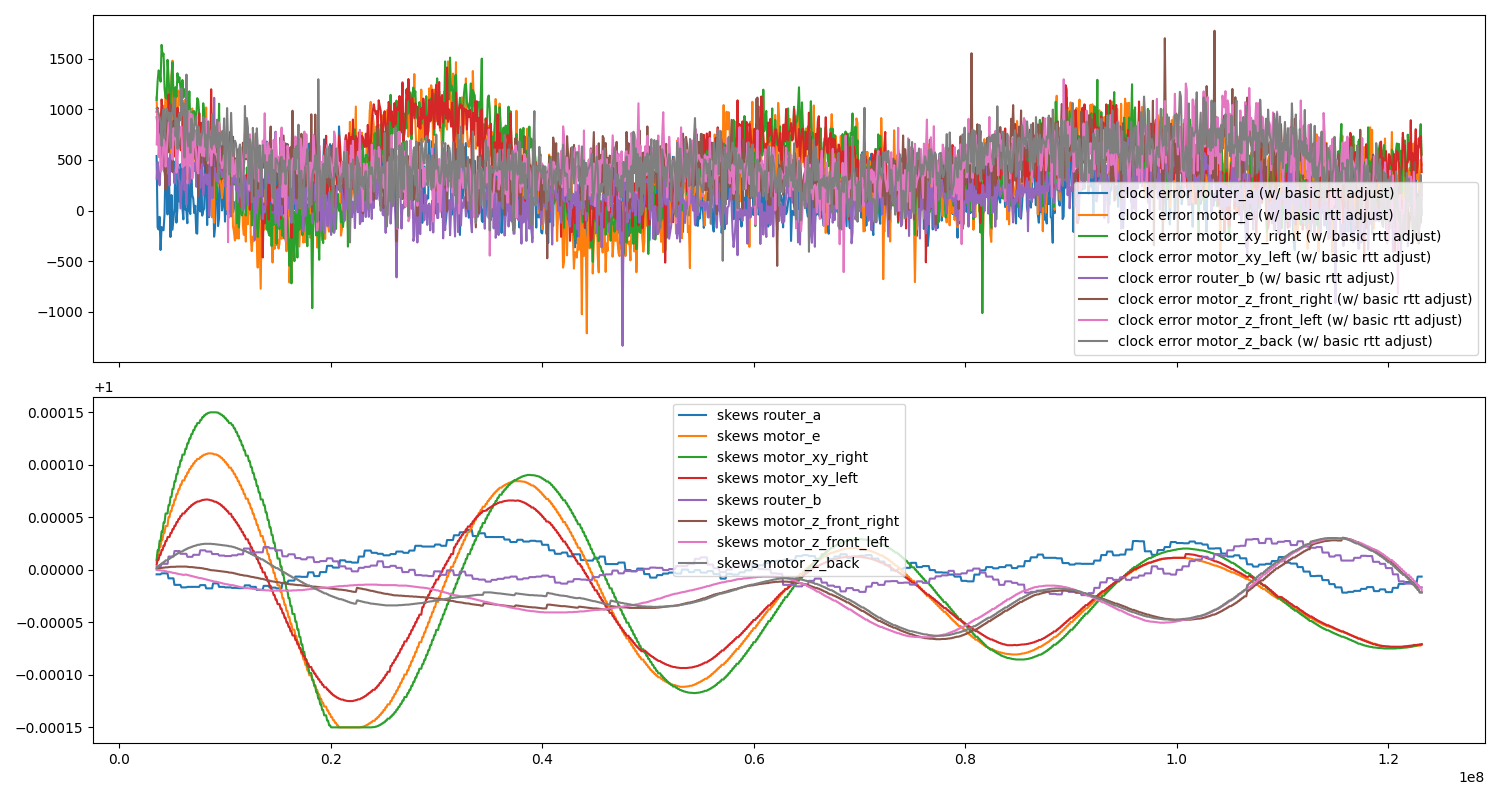

Distributed Clock Sync on 'any' Link: with under 1ms Error Target: 50us

Mills, David L. 1991. “Internet Time Synchronization: The Network Time Protocol.” IEEE Transactions on Communications 39 (10): 1482-93.

Eidson, John C, Mike Fischer, and Joe White. 2002. “IEEE-1588™ Standard for a Precision Clock Synchronization Protocol for Networked Measurement and Control Systems.” In Proceedings of the 34th Annual Precise Time and Time Interval Systems and Applications Meeting, 243-54.

Ciuffoletti, Augusto. "Using simple diffusion to synchronize the clocks in a distributed system." 14th International Conference on Distributed Computing Systems. IEEE, 1994.

Eidson, John C, Mike Fischer, and Joe White. 2002. “IEEE-1588™ Standard for a Precision Clock Synchronization Protocol for Networked Measurement and Control Systems.” In Proceedings of the 34th Annual Precise Time and Time Interval Systems and Applications Meeting, 243-54.

Ciuffoletti, Augusto. "Using simple diffusion to synchronize the clocks in a distributed system." 14th International Conference on Distributed Computing Systems. IEEE, 1994.

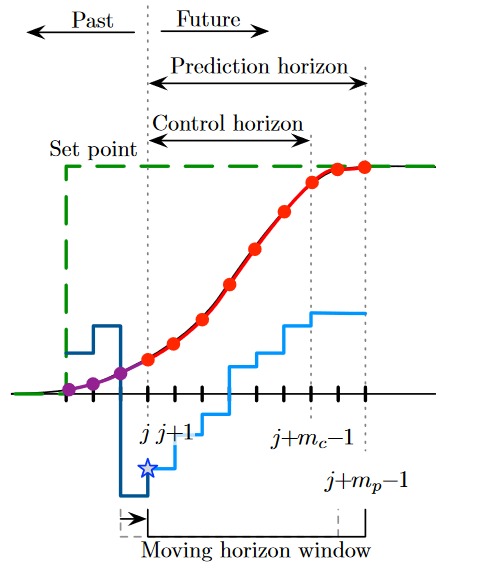

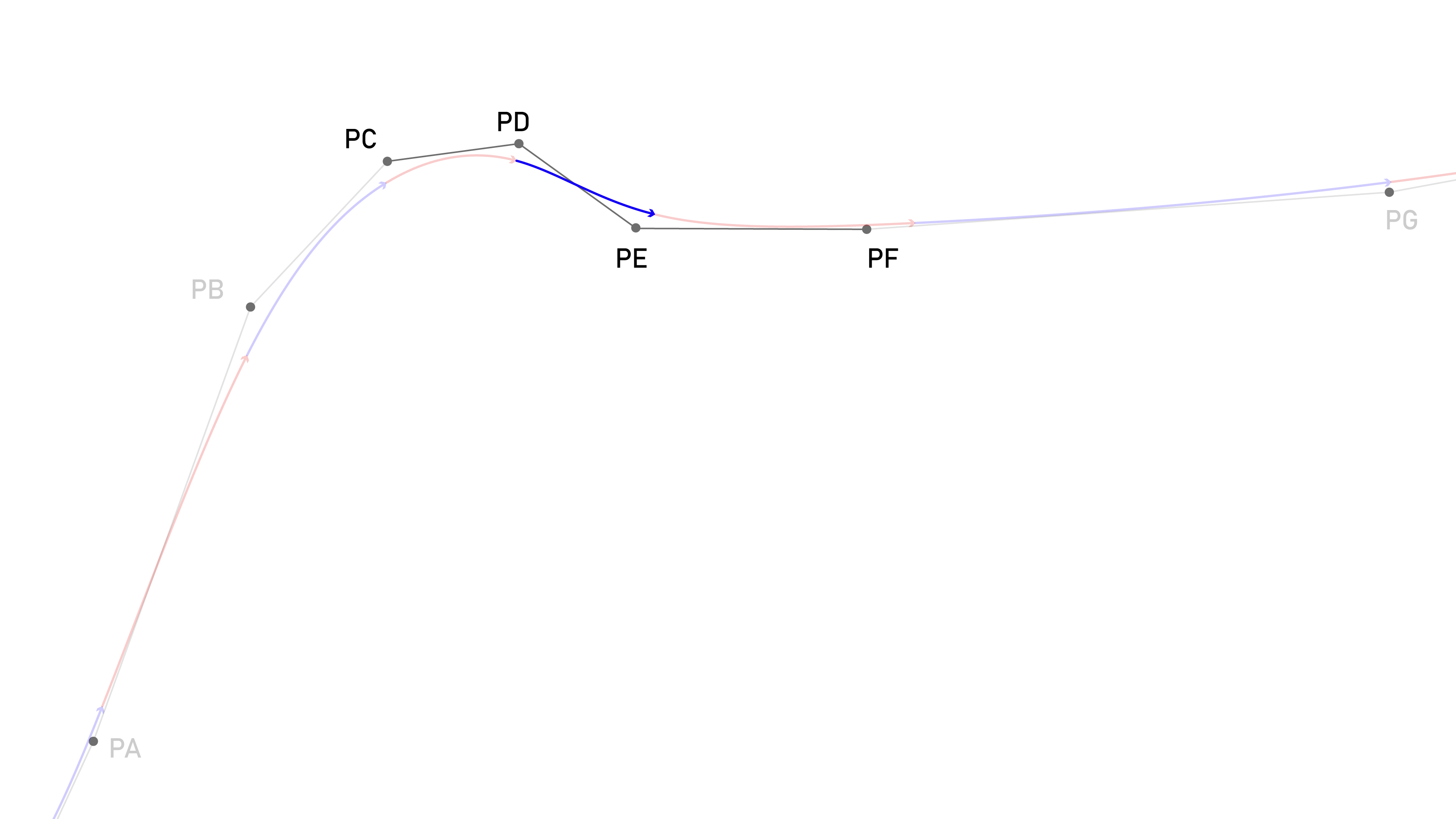

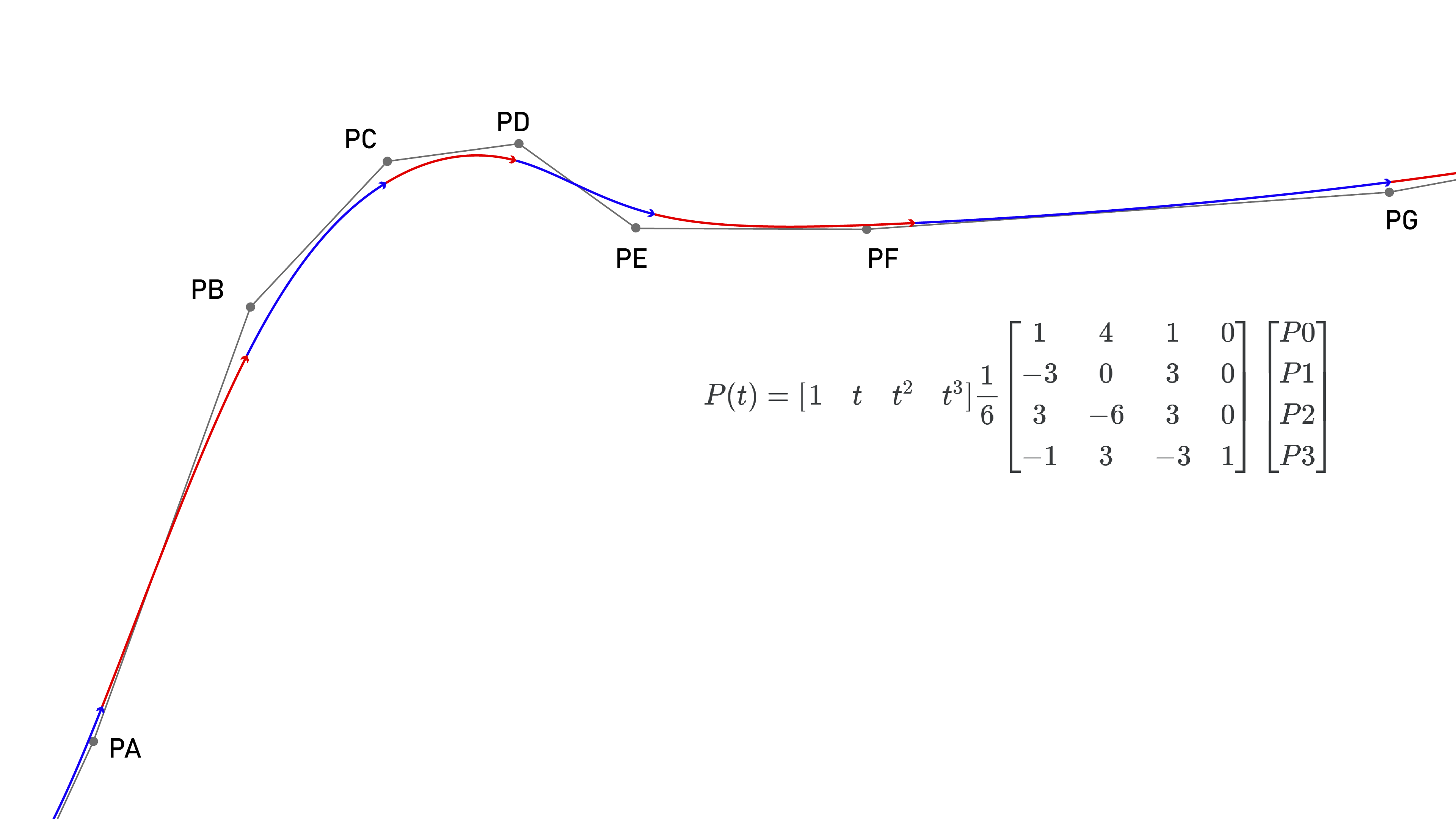

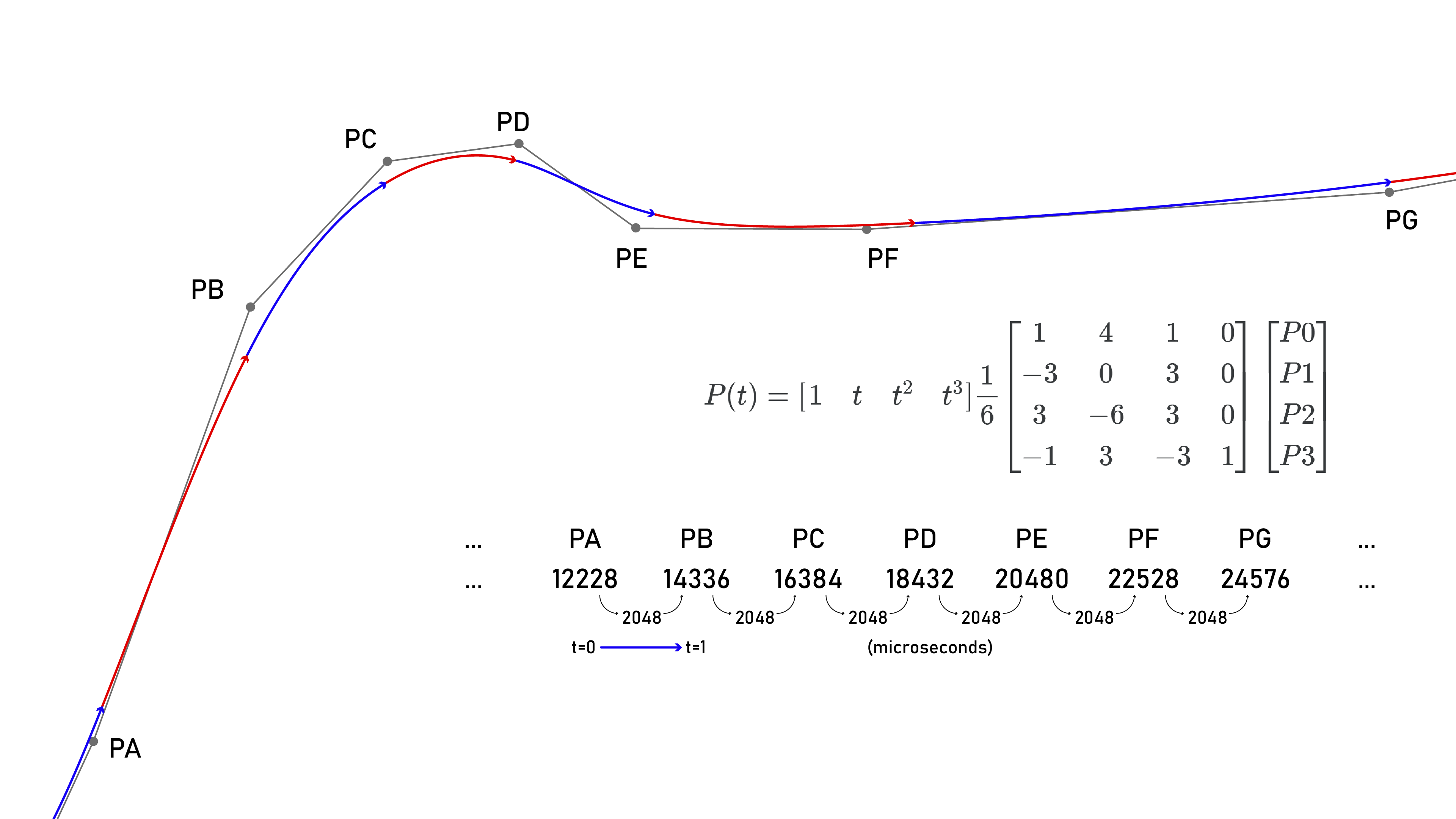

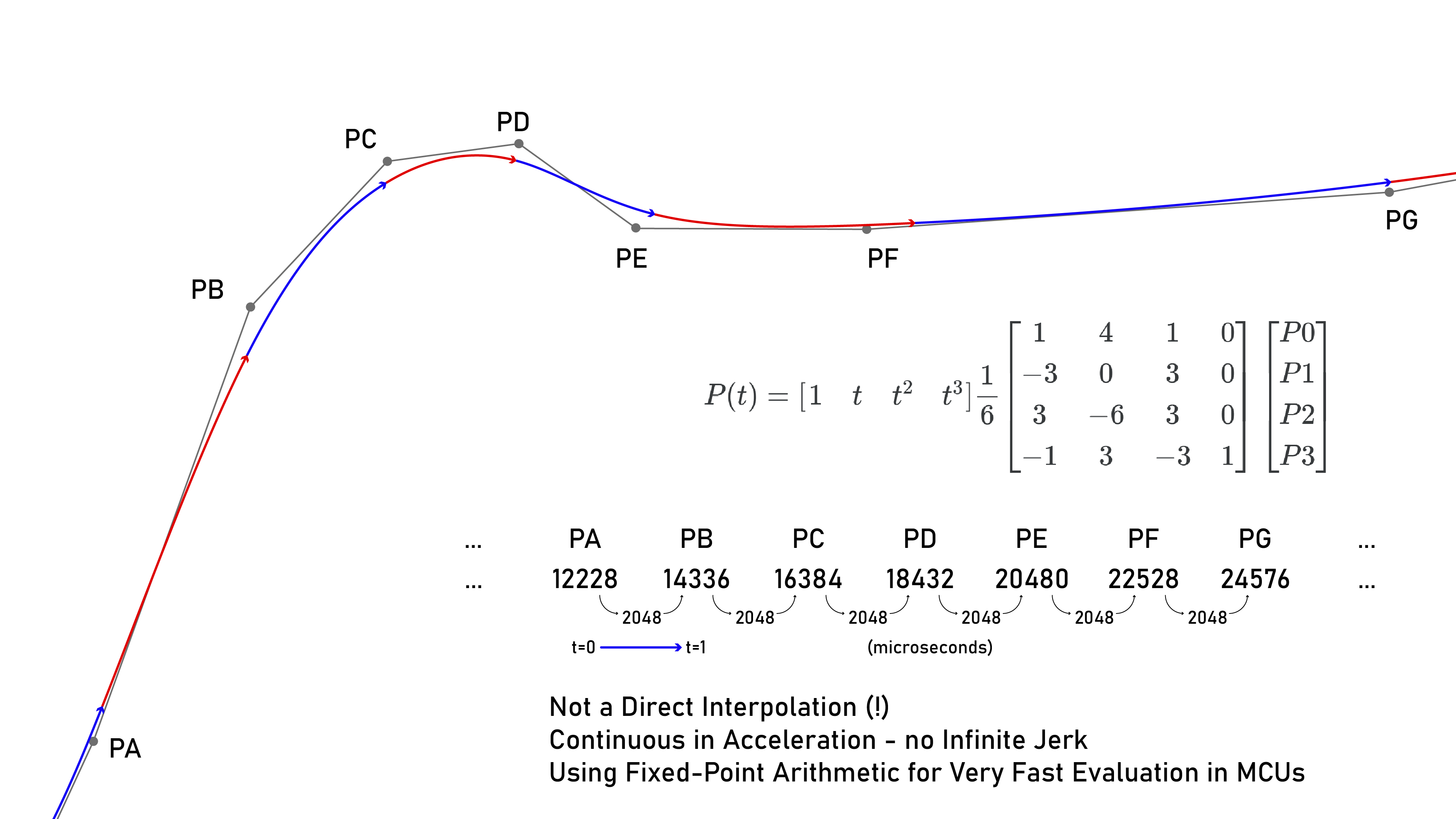

Fixed-Interval Basis Spline Segmentation

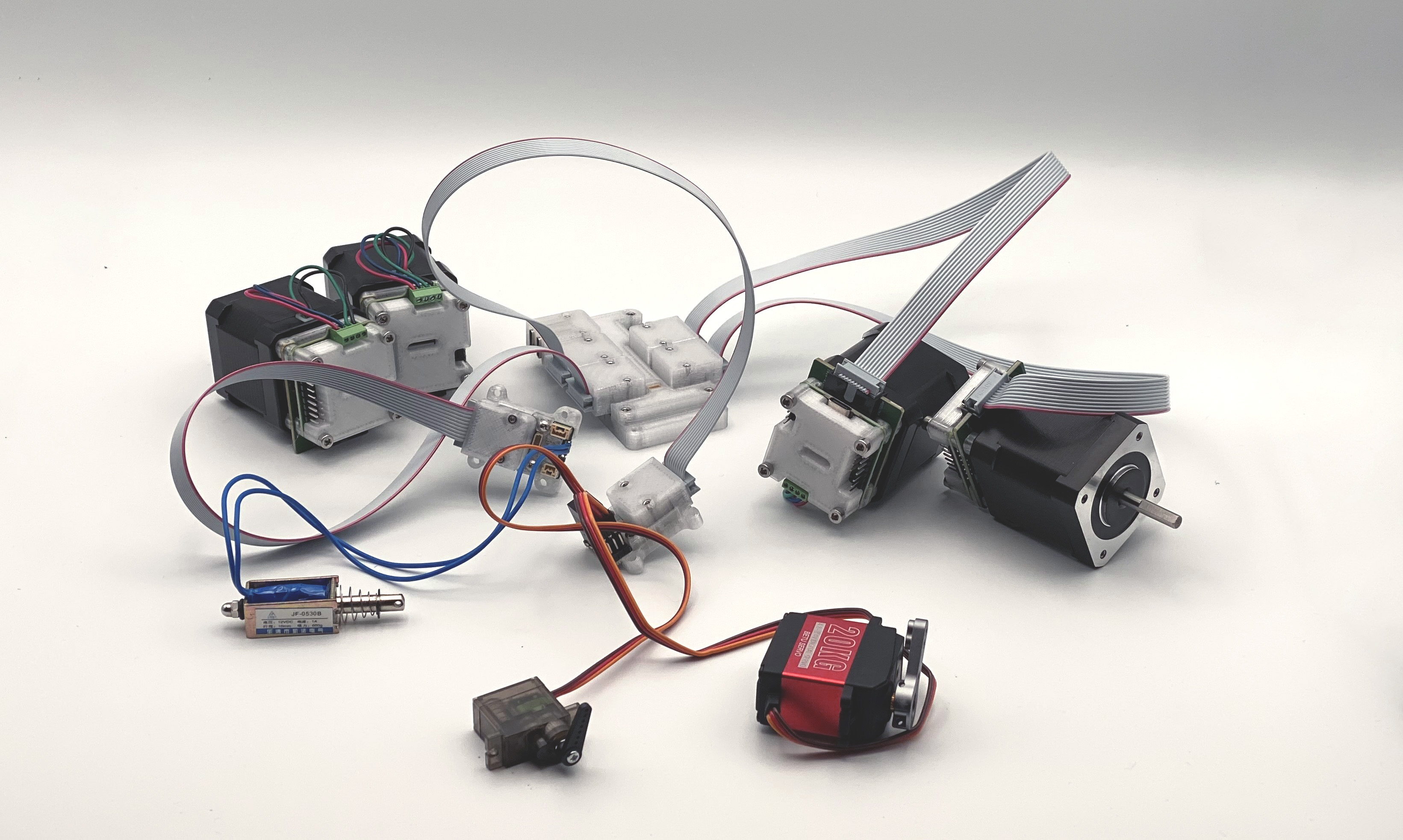

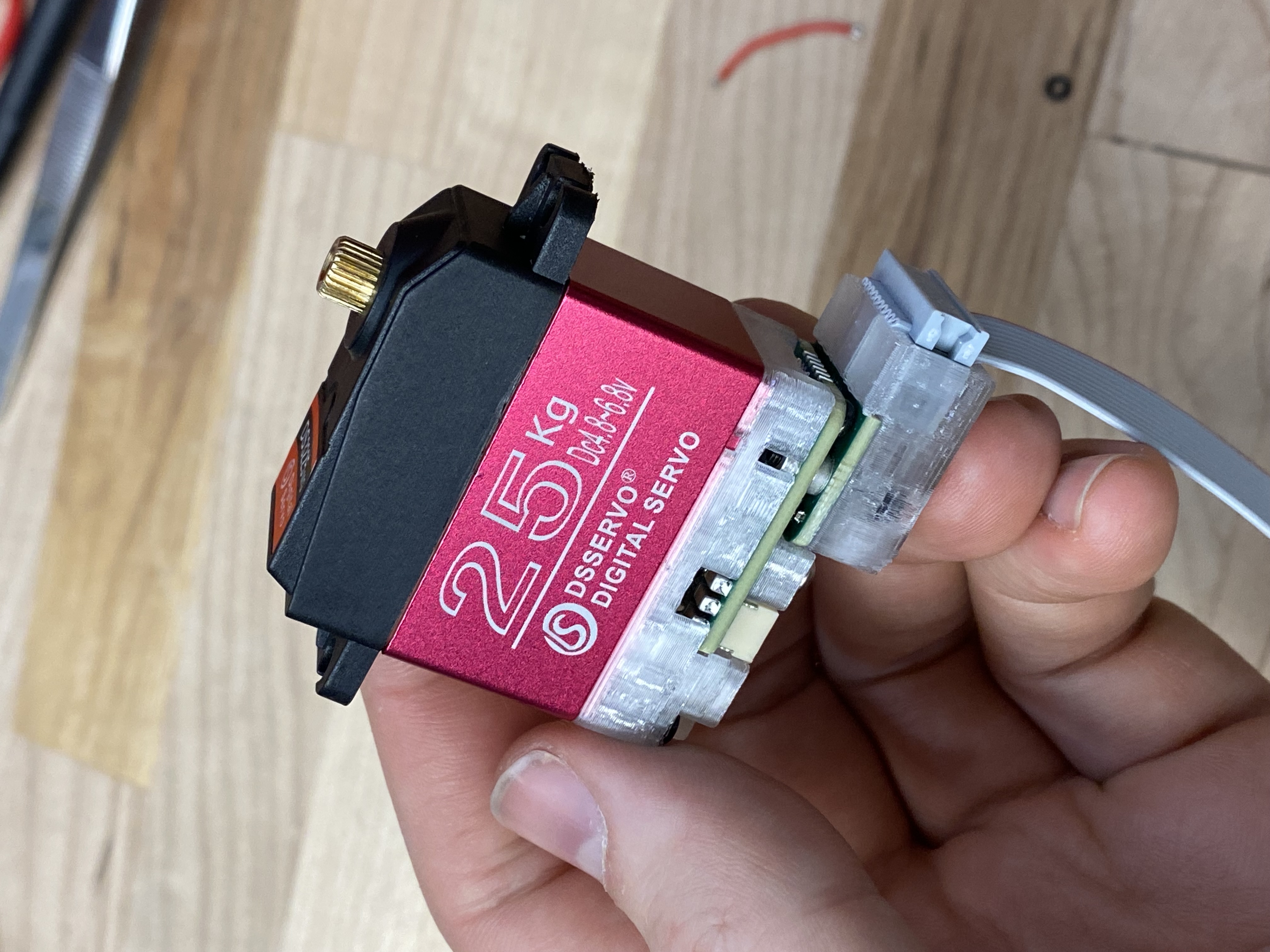

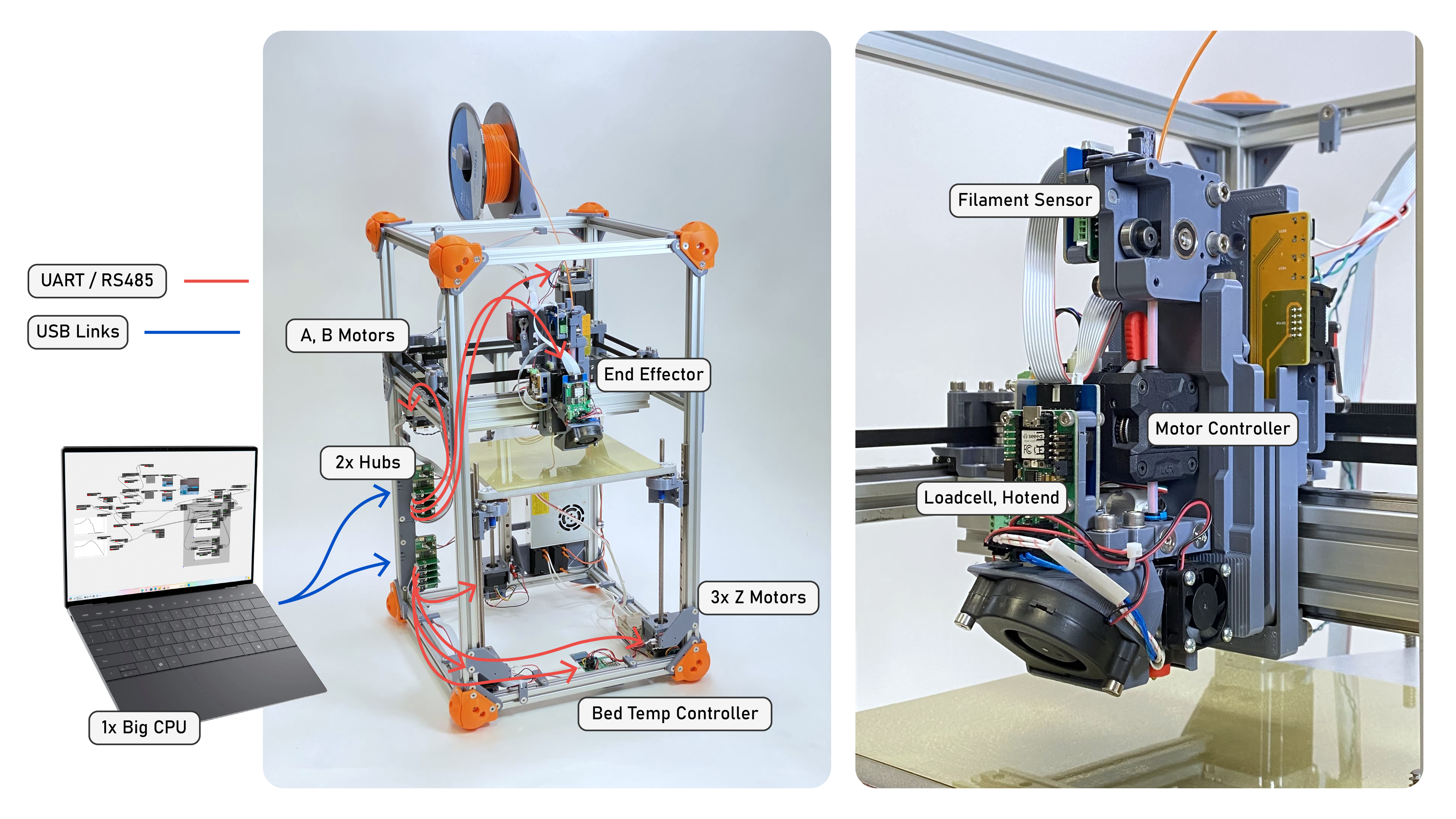

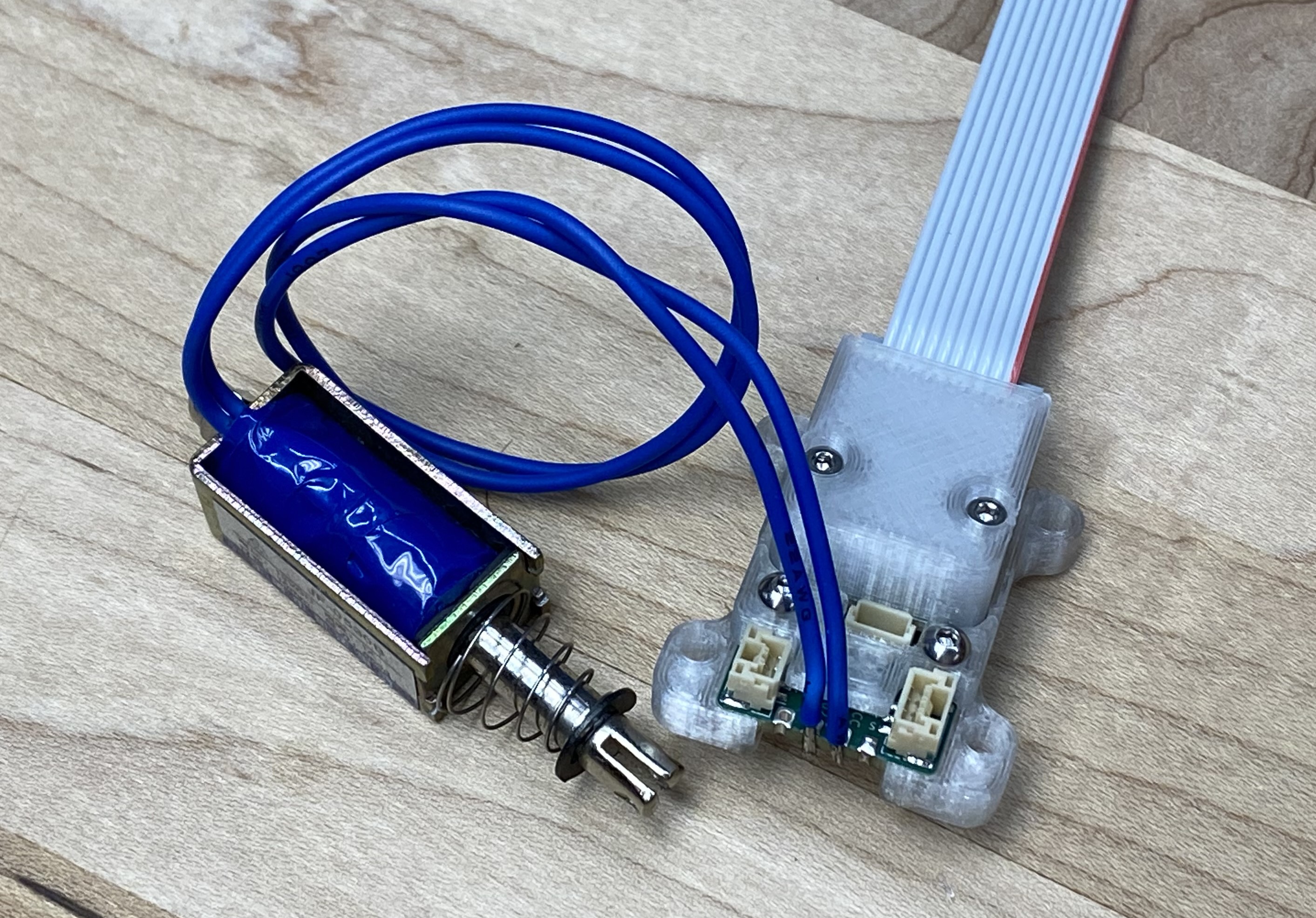

Swappable PHY's mean we can generalize modules across link layer technologies.

Hubs like this one let us assemble systems that span multiple link types.

Read, Jake Robert. Distributed dataflow machine controllers. Diss. Massachusetts Institute of

Technology, 2020.

mods.cba.mit.edu (Neil Gershenfeld + CBA), "Dynamic Toolchains" (Hannah Twigg-Smith, Nadya Peek)

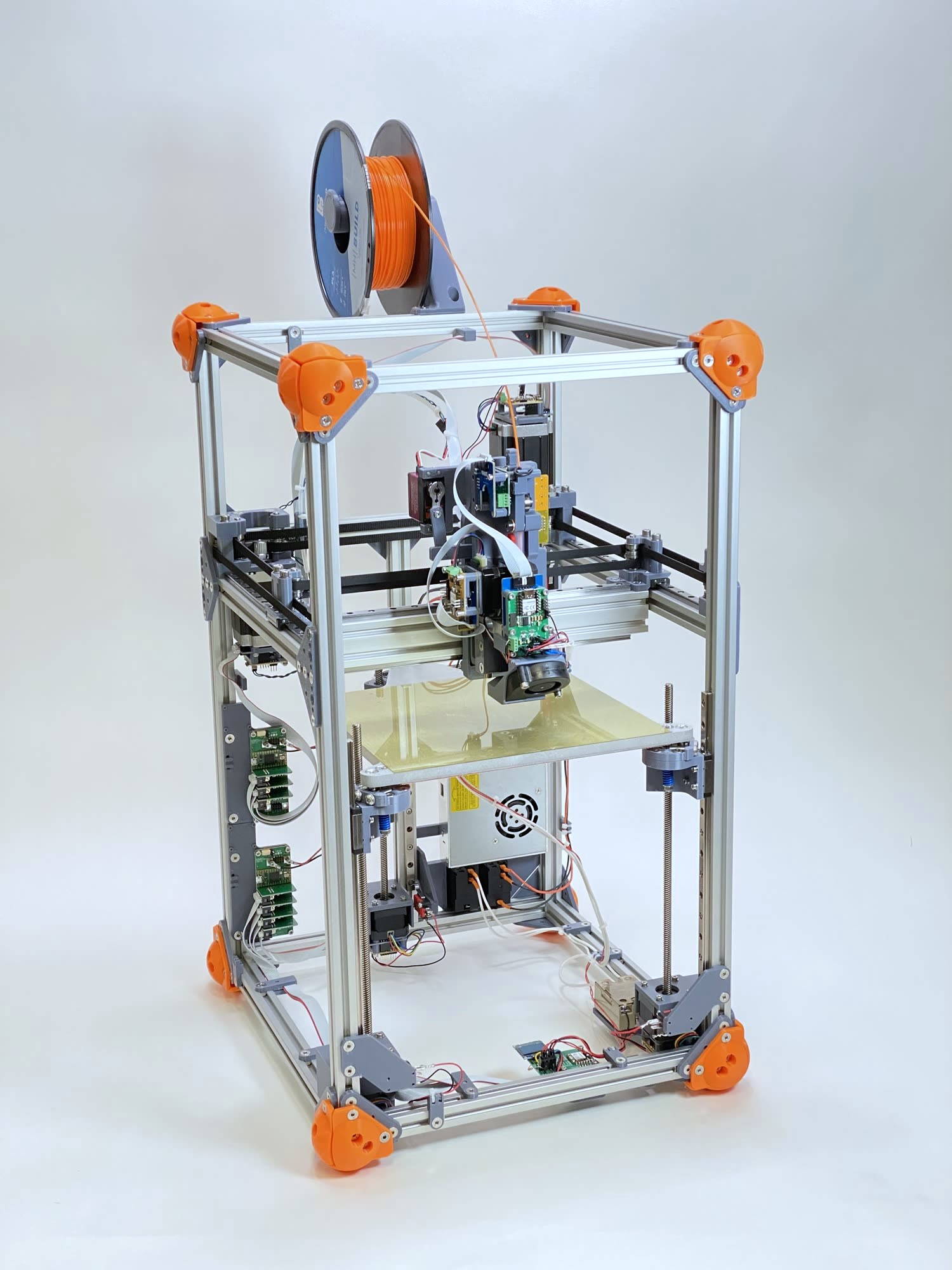

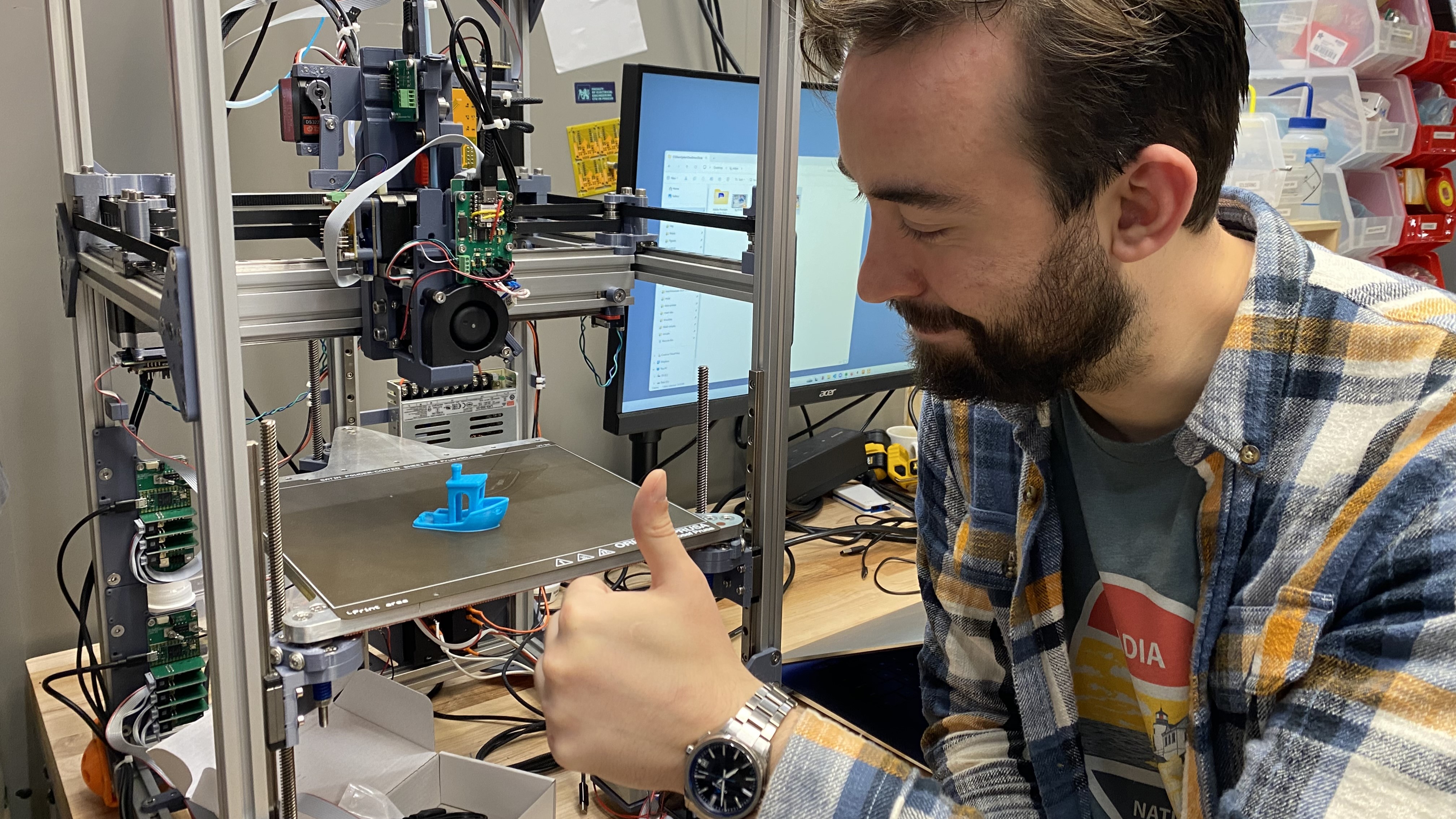

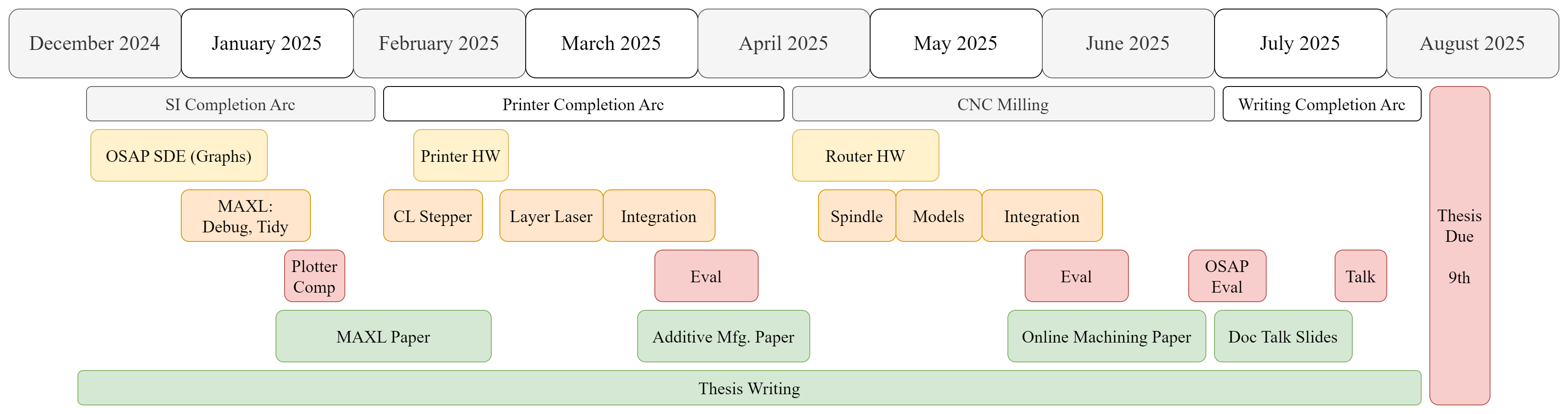

Printer Completion

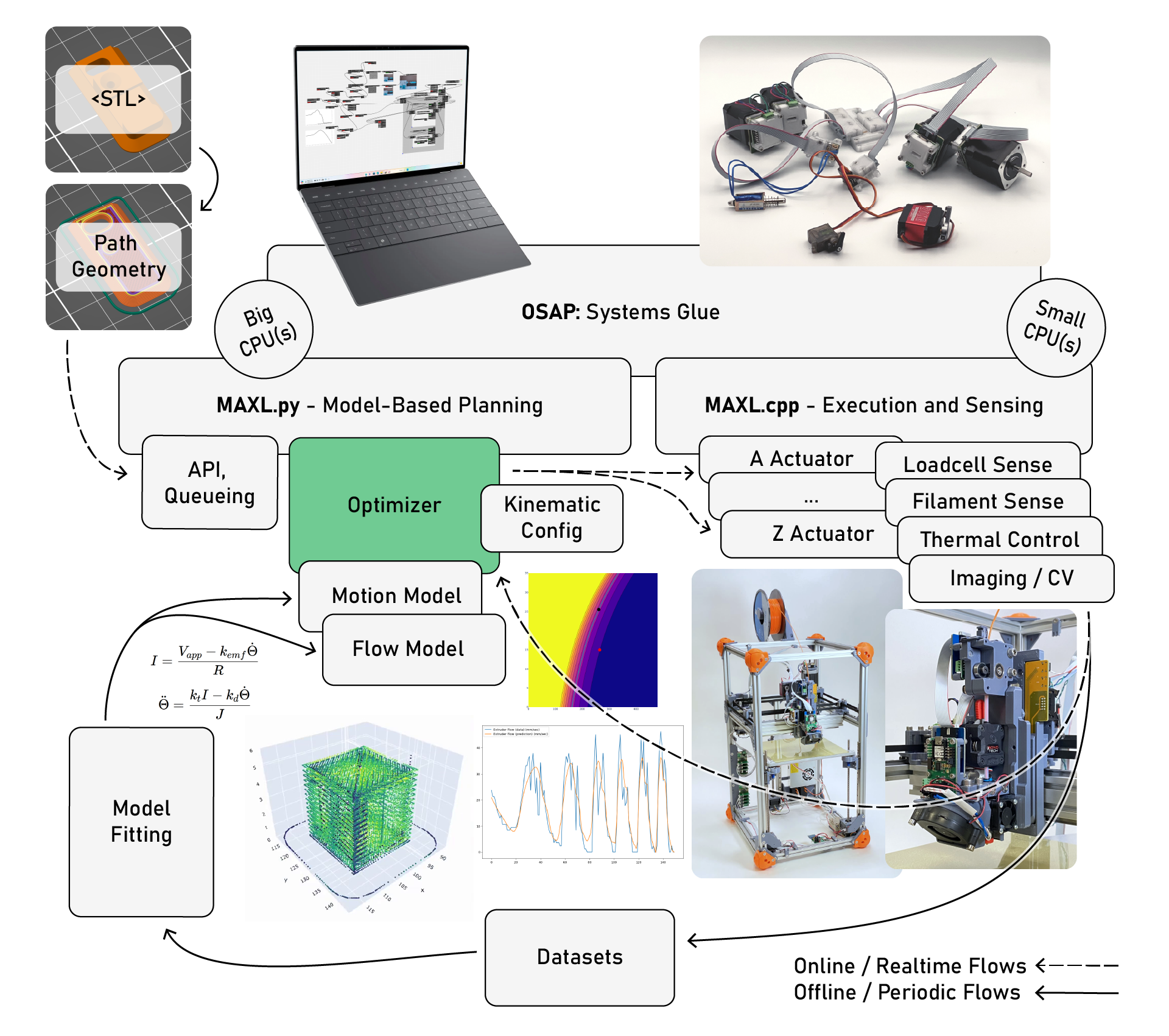

Bring the optimizer online, and close the outer loop - improving models continuously.

Evaluate:

- Performance (speed, precision) vs. SOTA

- Heterogeneity of materials.

- Number of parameters reduced.

- Performance (speed, precision) vs. SOTA

- Heterogeneity of materials.

- Number of parameters reduced.

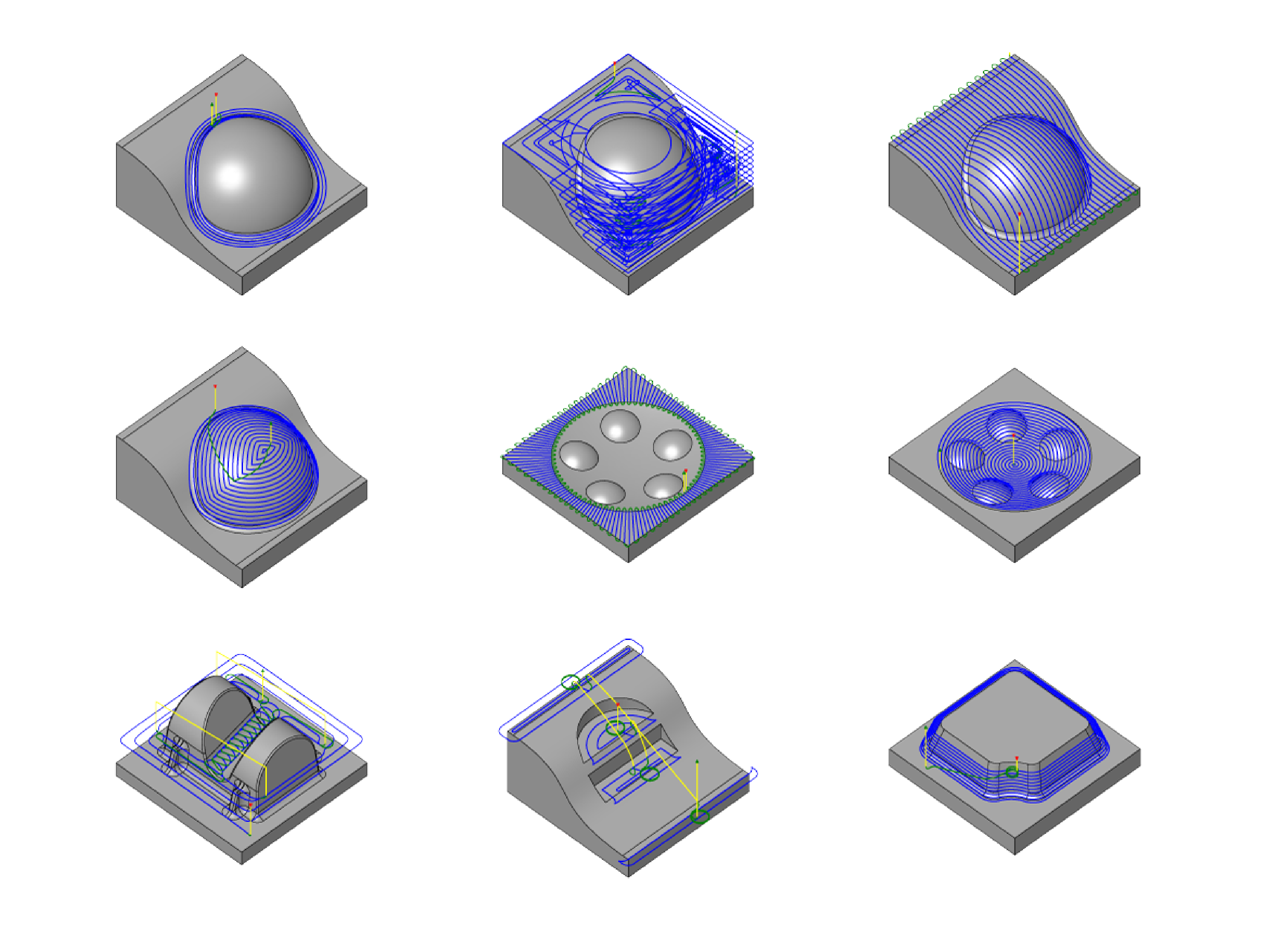

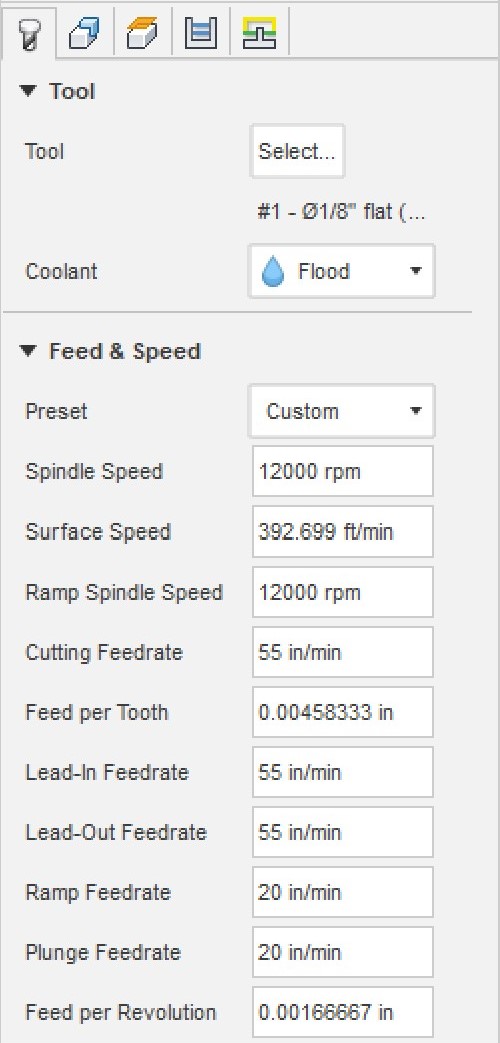

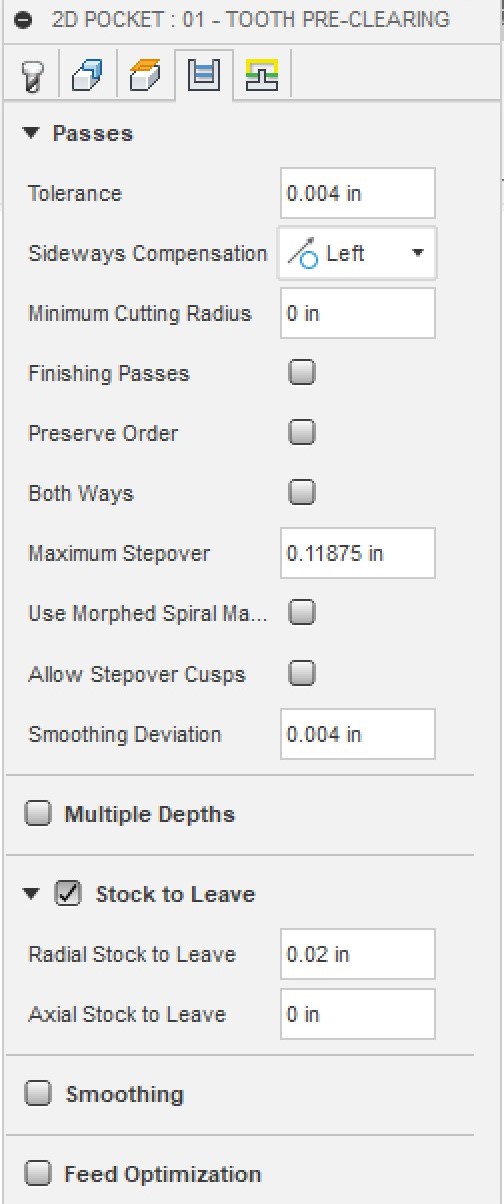

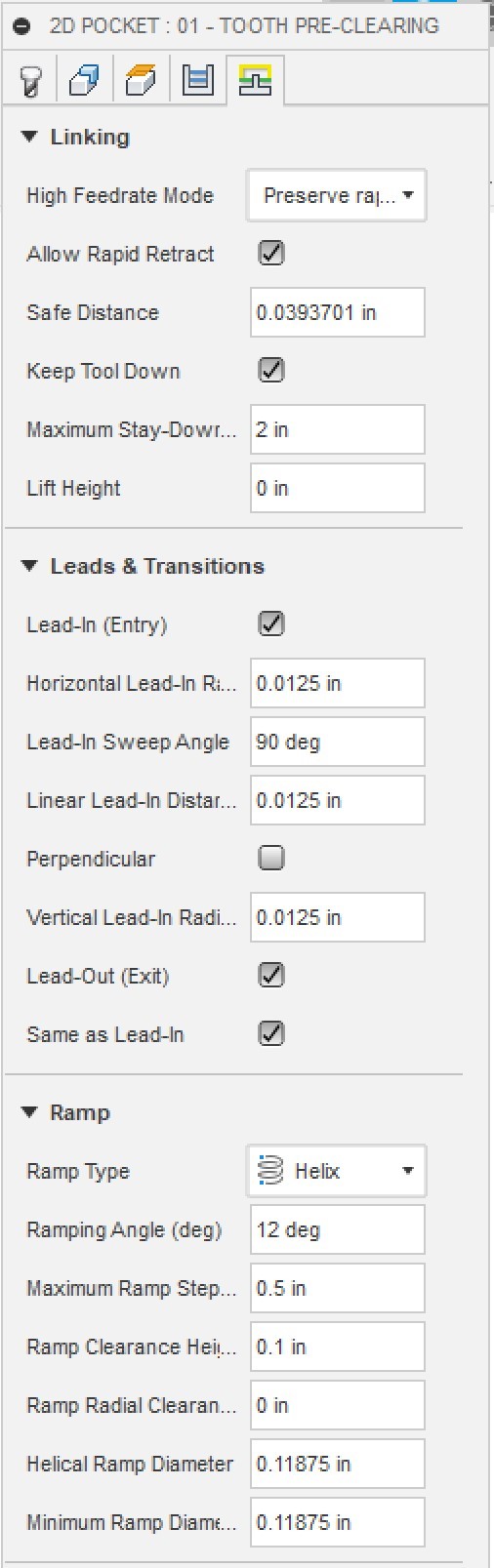

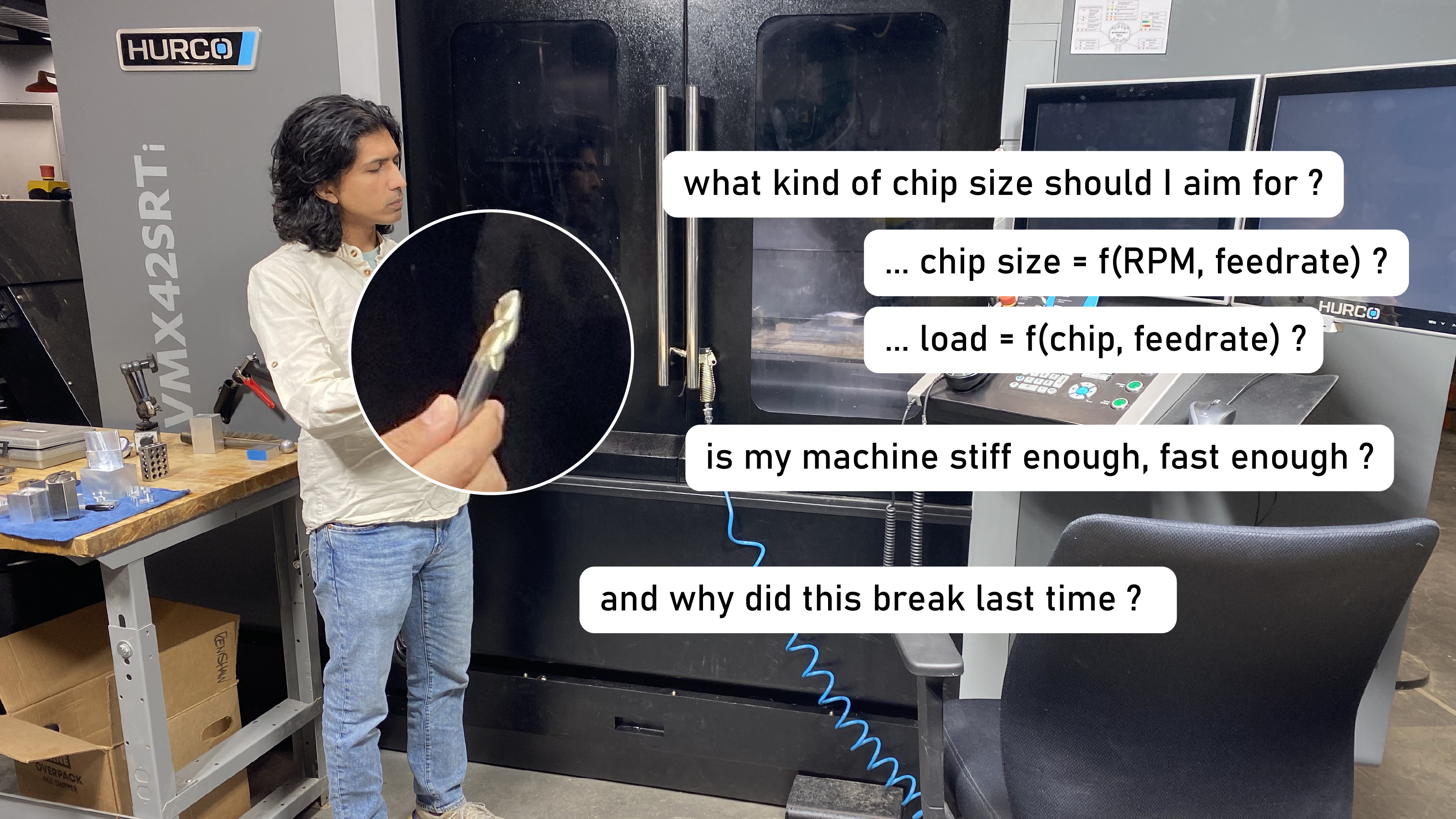

CNC Machining

Develop cutting and resonance models, deploy them in real time.

Evaluate:

- Performance vs. SOTA

- Adaptability across Materials and Tools

- Number of parameters reduced.

- Performance vs. SOTA

- Adaptability across Materials and Tools

- Number of parameters reduced.

MAXL

Polish MAXL interfaces, run the Plotter Comp

Evaluate:

- Spline Lossiness

- Performance

- Heterogeneity of Kinematics

- Deployability

- Spline Lossiness

- Performance

- Heterogeneity of Kinematics

- Deployability

OSAP

Continue development, Evaluate!

Evaluate:

- Size and Time overhead

- Networking overhead

- Time sync precision and jitter

- Reliability

- Size and Time overhead

- Networking overhead

- Time sync precision and jitter

- Reliability

Simple MLP to fit flow, given extruder history.

W/ Yuval Mamana

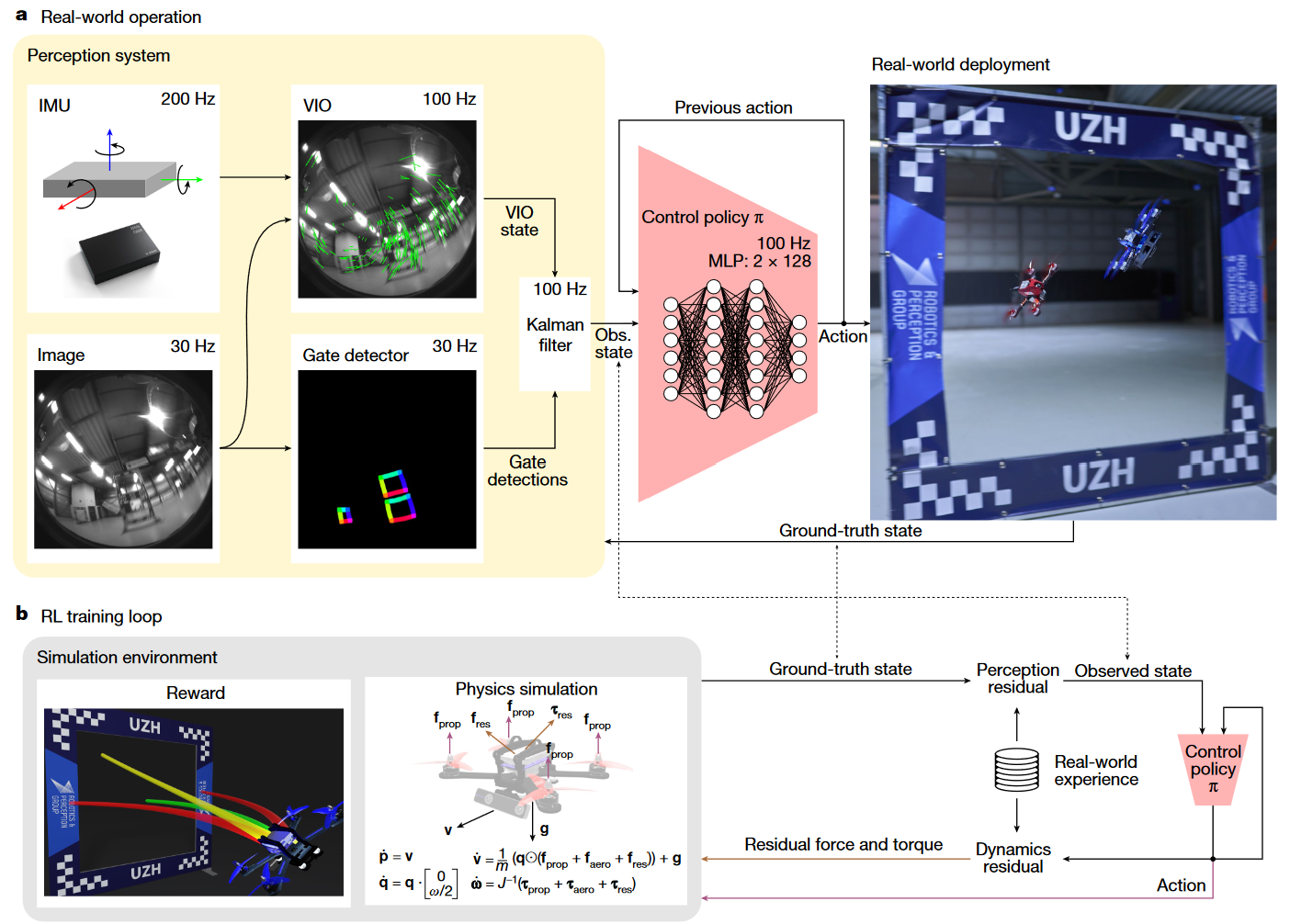

Kaufmann, Elia, et al. "Champion-level drone racing using deep reinforcement learning."

Nature 620.7976

(2023): 982-987.