How New GCodes Are Authored

I wanted to provide an example of how new GCodes are added to firmwares in off-the-shelf workflows, since it is somewhat common that machine developers need to work across these layers when developing new equipment.

- GCode Programs like the one below use

GxxandMxxcodes to define program operations.

L01 G21 ; use millimeters

L02 G28 ; run the homing routine

L03 G92 X110 Y120 Z30 ; set current position to (110, 120, 30)

L04

L05 G0 X10 Y10 Z10 F6000 ; "rapid" in *units per minute*

L06

L07 M3 S5000 ; turn the spindle on, at 5000 RPM

L08

L09 G1 Z-3.5 F100 ; plunge from (10, 10, 10) to (10, 10, -3.5)

L10 G1 X20 ; draw a square, go to the right,

L11 G1 Y20 ; go backwards 10mm

L12 G1 X10 ; go to the left 10mm

L13 G1 Y10 ; go forwards 10mm

L14 G1 Z10 ; go up to Z10, exiting the material

L15

L16 M5 ; stop the spindle

L17 G0 X110 Y120 Z30 ; return to the position after homing (at 6000)

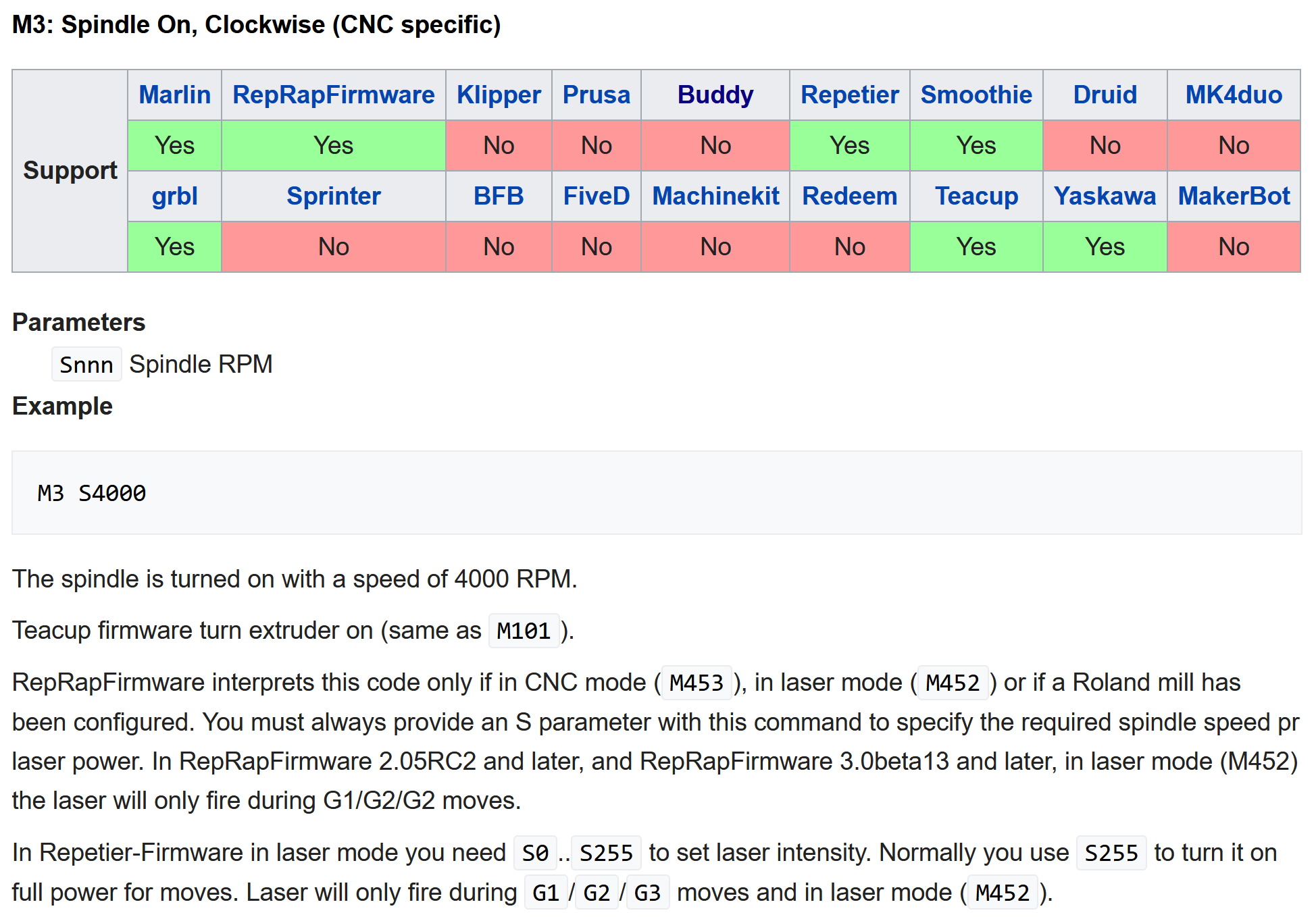

- Machine programmers use resources like RepRap’s GCode Table to track what individual codes (like the

M3at Line 07 above) should do (and whether they are supported on the particular firmware they are using). Machine vendors with closed controllers should provide a similar table.

- Each of those codes is implemented in firmware, below I show the snippet of cpp that defines the switch for any “M” code - here I am looking at the Marlin firmware, popular among hobbyist FFF printers. This snippet shows some compile flags

HAS_CUTTERthat are related to build-time firmware configurations. So, even if we can find this snippet of code, we still won’t know if the firmware that is currently running on our controller has implemented it - we would need to look at the configuration file as well.

// in Marlin/src/GCode/GCode.cpp

// line 477

case 'M': switch (parser.codenum) {

// ...

#if HAS_CUTTER

case 3: M3_M4(false); break; // M3: Turn ON Laser | Spindle (clockwise), set Power | Speed

case 4: M3_M4(true ); break; // M4: Turn ON Laser | Spindle (counter-clockwise), set Power | Speed

case 5: M5(); break; // M5: Turn OFF Laser | Spindle

#endif

// ...

}

// exit line 1172

- The actual implementation of the code can be found deeper in the firmware source, with another selection of compiler flags (

ENABLED(LASER_FEATURE)).

// in Marlin/src/GCode/control/M3-M5.cpp

void GCodeSuite::M3_M4(const bool is_M4) {

#if LASER_SAFETY_TIMEOUT_MS > 0

reset_stepper_timeout(); // Reset timeout to allow subsequent G-code to power the laser (imm.)

#endif

if (cutter.cutter_mode == CUTTER_MODE_STANDARD)

planner.synchronize(); // Wait for previous movement commands (G0/G1/G2/G3) to complete before changing power

#if ENABLED(LASER_FEATURE)

if (parser.seen_test('I')) {

cutter.cutter_mode = is_M4 ? CUTTER_MODE_DYNAMIC : CUTTER_MODE_CONTINUOUS;

cutter.inline_power(0);

cutter.set_enabled(true);

}

#endif

auto get_s_power = [] {

if (parser.seenval('S')) {

const float v = parser.value_float();

cutter.menuPower = cutter.unitPower = TERN(LASER_POWER_TRAP, constrain( v, 0, CUTTER_POWER_MAX), cutter.power_to_range(v));

}

else if (parser.seenval('O')) { // pwr in PWM units

const float v = parser.value_float();

cutter.menuPower = cutter.unitPower = CUTTER_PWM_TO_SPWR(constrain(v, 0, 255));

}

else if (cutter.cutter_mode == CUTTER_MODE_STANDARD)

cutter.menuPower = cutter.unitPower = cutter.cpwr_to_upwr(SPEED_POWER_STARTUP);

// PWM not implied, power converted to OCR from unit definition and on/off if not PWM.

cutter.power = TERN(SPINDLE_LASER_USE_PWM, cutter.upower_to_ocr(cutter.unitPower), cutter.unitPower > 0 ? 255 : 0);

};

if (cutter.cutter_mode == CUTTER_MODE_CONTINUOUS || cutter.cutter_mode == CUTTER_MODE_DYNAMIC) { // Laser power in inline mode

#if ENABLED(LASER_FEATURE)

planner.laser_inline.status.isPowered = true; // M3 or M4 is powered either way

get_s_power(); // Update cutter.power if seen

#if ENABLED(LASER_POWER_SYNC)

// With power sync we only set power so it does not effect queued inline power sets

planner.buffer_sync_block(BLOCK_BIT_LASER_PWR); // Send the flag, queueing inline power

#else

planner.synchronize();

cutter.inline_power(cutter.power);

#endif

#endif

}

else {

cutter.set_enabled(true);

get_s_power();

cutter.apply_power(

#if ENABLED(SPINDLE_SERVO)

cutter.unitPower

#elif ENABLED(SPINDLE_LASER_USE_PWM)

cutter.upower_to_ocr(cutter.unitPower)

#else

cutter.unitPower > 0 ? 255 : 0

#endif

);

TERN_(SPINDLE_CHANGE_DIR, cutter.set_reverse(is_M4));

}

}